Aluminum Coil Size Color Coated Aluminium Coils for Indoor Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Color Coated Aluminium Coils for Indoor Metal Wall ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Color Coated Aluminium Coils for Indoor Metal Wall ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

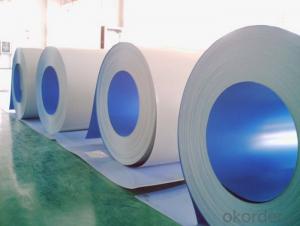

3. Color Coated Aluminium Coils for Indoor Metal Wall ACP Images

4. Color Coated Aluminium Coils for Indoor Metal Wall ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Color Coated Aluminium Coils for Indoor Metal Wall ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: Are aluminum coils affected by magnetic fields?

- No, aluminum coils are not affected by magnetic fields as aluminum is not a magnetic material.

- Q: How do I deal with too much aluminum powder when the aluminum strips are divided?

- At present, dust removal system distribution bag filter and water dust collector two kinds.

- Q: This question asks about the common applications of aluminum coil in everyday life.

- <p>Aluminum coil is widely used in daily life due to its lightweight, corrosion resistance, and thermal conductivity. It's commonly used in construction for roofing and siding, in the automotive industry for car parts, and in the packaging industry for food and beverage cans. It's also used in electrical applications like transformers and wiring due to its good conductivity. In the kitchen, aluminum foil is used for cooking and food storage, and in the HVAC industry for heat exchangers and ductwork. Its versatility makes aluminum coil an essential material in many industries and everyday applications.</p>

- Q: What are the different surface treatments available for aluminum coils?

- Aluminum coils offer a range of surface treatments, each with its own advantages and applications. The options include: 1. Mill Finish: This is the untreated standard surface of aluminum coils. It has a dull appearance and is suitable for industrial or structural uses where aesthetics are not a priority. 2. Anodizing: Anodizing is an electrochemical process that forms a protective oxide layer on the surface of aluminum coils. This treatment improves corrosion resistance, durability, and appearance. Anodized coils are often used in architectural applications like building exteriors and window frames. 3. Paint Coating: Various paints can be applied to aluminum coils to enhance their appearance, protect against corrosion, and provide additional functionality like heat reflection or insulation. Different thicknesses and finishes are available, catering to general use or specific industries like automotive or aerospace. 4. Brushed Finish: This treatment involves brushing abrasive materials onto the surface of aluminum coils to create a textured finish. Brushed coils have distinct patterns and are commonly used in decorative applications, interior design, or signage. 5. Embossed Finish: Aluminum coils can be embossed with patterns or textures to enhance their appearance or functionality. This process alters the surface, creating raised or recessed designs. Embossed coils find applications in architecture, automotive, and packaging. 6. Laminating: Aluminum coils can be laminated with various materials like films or foils for added protection, insulation, or decorative effects. The type of lamination material used determines the appearance, durability, or functionality enhancements. These examples highlight the available surface treatments for aluminum coils. The choice depends on specific requirements such as aesthetics, corrosion resistance, durability, or functionality. Selecting the appropriate treatment ensures the desired performance and longevity of the coils in their intended use.

- Q: Are aluminum coils suitable for electrical insulation?

- No, aluminum coils are not suitable for electrical insulation as aluminum is a conductor of electricity, meaning it allows the flow of electric current rather than insulating it.

- Q: Are aluminum coils suitable for insulation jacketing?

- Indeed, insulation jacketing can be effectively achieved with aluminum coils. Renowned for their exceptional thermal properties, durability, and resistance to corrosion, aluminum coils are a highly favored choice for jacketing material. They find extensive application across diverse industries such as HVAC, oil and gas, and petrochemical, where they serve to insulate pipe systems and equipment. By enveloping insulation materials, aluminum coils play a crucial role in safeguarding against moisture infiltration and sustaining thermal efficiency. Moreover, their lightweight composition ensures effortless installation and transportation. Ultimately, aluminum coils emerge as a dependable and efficient solution for insulation jacketing endeavors.

- Q: On Square-D service panels, are the main lugs rated for aluminum wire? Or do I need to use an anti-oxidant compound? What about on Milbank outdoor meter bases?

- No you do not have to use any type compound on it.

- Q: How are aluminum coils protected from corrosion?

- Aluminum coils are protected from corrosion through various methods and coatings. One common method is anodizing, which involves immersing the coils in an electrolyte solution and passing an electric current through them. This process forms a thick oxide layer on the surface of the aluminum, providing excellent corrosion resistance. Another method is the application of a protective coating. Aluminum coils can be coated with organic or inorganic coatings, such as polyester, epoxy, or polyvinylidene fluoride (PVDF). These coatings act as a barrier, preventing moisture and corrosive substances from reaching the aluminum surface. Additionally, aluminum coils can be protected through the use of sacrificial coatings. This involves applying a layer of a more reactive metal, such as zinc or magnesium, onto the aluminum surface. These sacrificial coatings corrode before the aluminum does, effectively protecting it from corrosive elements. Regular cleaning and maintenance also play a crucial role in preventing corrosion. Accumulated dirt, debris, and corrosive substances should be regularly removed from the surface of the coils to maintain their corrosion resistance. Overall, a combination of anodizing, protective coatings, sacrificial coatings, and proper maintenance ensures that aluminum coils are effectively protected from corrosion, extending their lifespan and maintaining their performance.

- Q: Are aluminum coils suitable for thermal insulation?

- No, aluminum coils are not suitable for thermal insulation. Aluminum is a highly conductive material, meaning it readily transfers heat. This makes it ineffective in preventing heat transfer between different areas or maintaining a desired temperature within a space. For thermal insulation purposes, materials with low thermal conductivity, such as fiberglass, mineral wool, or foam insulation, are preferred as they minimize heat transfer and provide better insulation.

- Q: A cube of solid aluminum has a volume of 1.00 m3 at 20°C. What temperature change is required to produce a 130 cm3 increase in the volume of the cube?

- The linear expansivity of aluminum is 23 x10^-6 /K. Bulk expansivity is 3 x 23 x10^-6 / k For 130 [cm^3] the temperature required is 130 [cm] ^3/ 3 x 23 x10^-6 = 0.00013/[3 x 23 x10^-6] = 1.88 K ========================= If each side of the cube of side 1m expands by e, then its new volume = [1+e]^3 = 1 + 3e + 3e^2 +e^3. Neglecting high powers of e as negligible, the increase in volume is 3e. But e = 23 x10^-6 x rise in temperature 3e = 3*23 x10^-6 x rise in temperature. Given 3e = 0.00013 0.00013= 3*23 x10^-6 x rise in temperature Rise in temperature = 0.00013 / 3*23 x10^-6 = 1.88 K

Send your message to us

Aluminum Coil Size Color Coated Aluminium Coils for Indoor Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords