Alcoa Aluminum Coil Primrose Yellow Coated Sheet Metal Roofing Material

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

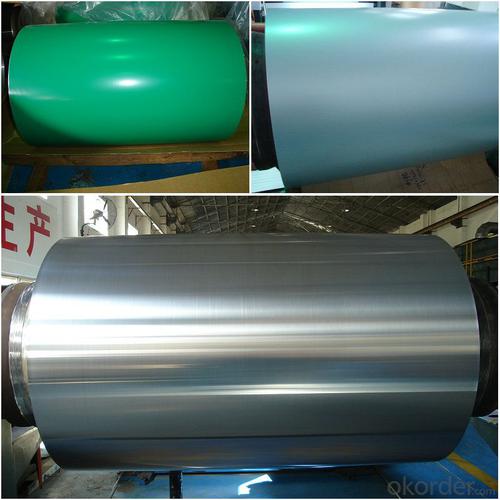

Color coated aluminum coil

isa material with excellent acid-resistance and alkali-resistance. The coating layer is even with bright color to last for a very long time. It is a greendecoration material with the characters of environment protection,flame-resistance, and groovy colors. In nowadays, the color coatedaluminum coil has become the popular material for top grade decoration. With our advance professional aluminum coated technique, wecan custom various aluminum coils ,like coated aluminum coil , Color coatedaluminum coil , embossed aluminum sheet with the color and size which youdemands.

1)Process: pre-treatment, continuous painting and baking for times .

2)Material: high quality material, aluminum sheets from South West AluminumIndustry Company in China, pre-treatment material from Henkel & Chemtellfrom Germany, more than 70% of PVDF coating from PPG Corp., the USA andpolyester from Sweden Becker Industrial Coating Co., Ltd.

3) Ourproducts can keep excellent quality and stability.

4)Thickness: 0.06 - 1.0mm; width: 20 - 1,590mm

Applications:

The aluminum coils are widely used in ACP/curtainpanel/honey comb panel/shutter/roofing and most of the decoration areas. Withthe superior quality and advanced management, our products had been export toEuro/North America /East Asia and many other areas and countries.

Used for manufacturedecorative materials, such as aluminum veneers, ACP aluminum composite panels,honeycomb panels, aluminum roofing, lighting decoration, household electricalappliances, food package(such as pop can cover and ring-pull),and furnitureetc.:

1) Exteriorapplications: wall cladding, facades, roofs and canopies, tunnels, columncovers or renovations;

2) Interiorapplications: wall cladding, ceilings, bathrooms, kitchens and balconies;

3)Advertisement and market applications: display platforms, signboards, fasciasand shop fronts;

4) Transportand industrial applications

Aluminum Coil:Chinalco Ruimin / Southwest Aluminum / Alnan Aluminum / Nanping Aluminum inchina

Pre-treatment:Henkel from

Paint:

<3>AluminumCoil size

Alloy: Mainly A1100,A3003, A3005, A3105, A5052, A5182, A8011 or others

Temper: MainlyH14, H16, H18, H24, H26, H44, H46 or others

Thickness:0.06mm-1.0mm

Width: 30mm-1590mm,our slitting machine can do width cutting from 0.2mm to 1.0mmthickness.

Length: 1200mm more or less

<4>ProductionTypes

PVDF / PE /Chromate Mill Finish / Single side brushed / Orange peel embossed / Hydrophilic coatedaluminum foil for air condition

PVDF Coating Thickness:

PVDF 2 Coating: Bottom (7µm±1),Top(17µm±1)

PVDF 3 Coating: Bottom (7µm±1),Top(17µm±1),Varnish(10µm±1)

PE Coating Thickness:

PE 1 Coating: 7µm±1(<0.1mm)>0.1mm)

PE 2 Coating: Bottom (7µm±1),Top(17µm±1)

Backing: 7µm±1

Epoxy: 7µm±1

Can Ring-Pull: 3µm±1 (both sides)

Can Cover: inside (10µm±1) outside(3µm±1)

Color:

PVDF Color

Solid:

Ivory white color series

Deep solid color series: brown / deep grey / coffee/ black

Bright-colored solid color series: green / yellow

Deep bright-colored solid color series: blue / red

Metallic:

White silver grey color

Medium silver grey color

Flash silver color

Mica:

Mica champagne color

Mica gold color

PE Color:

Solid Color:

White series: white, milky white, grey white,ivory, matt white, high gloss white and so on.

Colorful series: green, yellow, red, grey, brownand so on.

Metallic Color:

Solid silver series: flash silver, fine silver,silver grey and so on.

Colorful silver series: champagne silver, galaxyblack and so on.

Pearly-lustre Color series:

Solid pearl series: white

Colorful pearl series: pink, light grey, sky blue,light green and so on.

<5>More Specifications

Coil Weight: 0.5-4Ton/Coil, or by buyer's option

Interior Diameter: 405mm or 505mm or 150mm or 75mm

Color: RAL Standard or by your sample

Min order: 7Ton for one size one color

Delivery: 15-20days for generalspecification and 35days for special specification after receiving the deposit.

Terms of Payment: T/T FIRST or L/C AT SIGHT

<6>Packing

Damp proof film, Kraft paper, Steel strip, woodenpallet /Case

PE Aluminum Coating Coils for ACP

Featuresof PE Aluminum Sheet:

1.Adopting precision rolling coating technology, our PVDF and PE coated coil canensure excellent adhesive without coating omission.

2. For thePE coated aluminum coil we produced, there are various colors for your choice.

3. Usinginfrared heating technology to protect environment from pollution.

4. Ourcoated aluminum coil has four-roller coating line, uniform coating thicknessand good features.

RawMaterial of the PE Aluminum Coating Coils:

1. Aluminum Coil: high strength aluminum withalloy of AA1100 (aluminum alloy is available with AA3003, AA3005, AA5005according to customer)

2. Surface Paint: PE, PVDF and specialpaints.

Specification of PE Aluminum Coating Coil

Width: 20mm~1590mm

Thickness: 0.06mm~1.0mm

External Diameter: ≤ 1500mm

Internal Diameter: 405mm, 505mm, 150mm, 75mm

Coil weight: ≤ 4000kg

PE coated aluminum coil is processed throughthe technics of roller coating and baking with precise polyester paints. Itscolor is glossy and with variety of colors enabling you to choose easily.Chromatic aberration is small, impact resistance is strong and easy to beprocessed, and all its performance has reached or surpassed the nationalcriteria. The products are widely used in indoor and door decoration, ceilings,room surface tiles, corrugated boards, wallpanels, advertisement boards, counters, home appliances, decoration in and outof autos and boats.

Performance of thecoating

Aluminum Thickness | Coating Thickness | MEK | T- Bend | Impact | Adhesion | Pencil Hardness | Boiling Water Proof |

0.3-1.5mm | ≥18μm | ≥100 Times | ≤2T | 50 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.2-0.28mm | ≥18μm | ≥100 Times | ≤2T | 30kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.15-0.18mm | ≥18μm | ≥100 Times | ≤3T | 20 kg•cm | 0 Grade | ≥HB | no change within 2 hours |

0.08-0.12mm | ≥16μm | ≥80 Times | ≤4T | 10 kg•cm | ≤1 Grade | ≥HB | no change within 1 hour |

0.022-0.06mm | ≥12μm | ≥50 Times | - | - | ≤1Grade | ≥HB | no change within1 hour |

Color of Card

PE (polyester)

PE

Color Match

For custom' color requests, we can deal as following:

1. Supply a physical sample of custom color. A color sample on metal ispreferred. If other, it is also acceptable. But the color matching rate may benot good as color on metal.

2. New color sample is usually offered by our paint supplier in 5-7 days,special color should be in 7-10 days.

3. Upon receipt of color sample, please approve in writing as soon as possible.Once you approved, we will arrange purchasing and production.

Note: Color difference maybe occurred in different production batch, so it issuggested all panels are placed in one order for same project. And keep samedirection as arrow on protective film when installing to avoid any colordifference by vision

- Q: What precautions should be taken while using tools for handling aluminum coils?

- <p>When handling aluminum coil tools, it's crucial to follow safety measures to prevent accidents. Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and closed-toe shoes. Ensure the tools are in good condition and well-maintained. Keep the work area clean and free of debris to avoid slips or trips. Be cautious of sharp edges on the aluminum coils, as they can cause cuts. Use lifting equipment when necessary and never attempt to lift heavy coils manually. Follow all manufacturer guidelines for the safe operation of the tools. Regularly inspect the tools for any signs of wear or damage and replace them as needed.</p>

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils play a key role in enhancing the energy efficiency of appliances. The use of aluminum in coil form allows for efficient heat transfer, which is essential for appliances that require cooling or heating mechanisms. Firstly, aluminum coils have excellent thermal conductivity. This means that they can quickly absorb and dissipate heat, resulting in more efficient cooling or heating processes. This is especially important in appliances such as refrigerators, air conditioners, and heat pumps, where effective heat transfer is crucial for maintaining the desired temperature. Moreover, aluminum coils are lightweight yet durable, making them an ideal choice for energy-efficient appliances. The lightweight nature of aluminum reduces the overall weight of the appliance, which leads to lower energy consumption during transportation and installation. Additionally, the durability of aluminum ensures a longer lifespan for the appliance, reducing the need for frequent maintenance or replacement. Furthermore, aluminum is highly resistant to corrosion, which is a common issue in appliances that involve contact with water or moisture. By using aluminum coils, manufacturers can ensure the longevity and reliability of the appliance, thus contributing to energy efficiency by reducing the need for repairs or replacements. Lastly, aluminum is a highly recyclable material. Using aluminum coils in appliances promotes sustainability and reduces the environmental impact. By choosing energy-efficient appliances that incorporate aluminum coils, consumers can support the circular economy and contribute to a more sustainable future. In conclusion, aluminum coils greatly contribute to the energy efficiency of appliances. Their excellent thermal conductivity, lightweight yet durable nature, corrosion resistance, and recyclability make them an ideal choice for enhancing the performance and sustainability of energy-efficient appliances.

- Q: I know aluminum has gone up in price. I know very little about gutter material. Durability, leaf guards, etc. I am on a limited income, and need the most and best for my few bucks. Thanks Lee

- ALUMINUM!!!!!!!!!!!!!!!!!!

- Q: Just wondering if an aluminum and Fluoride bond can be created by boiling fluoridated water in aluminum cookware?

- Yes. okorder /

- Q: How much fluorocarbon and polyester paint should be used in production of aluminum coil and aluminum-plastic panel?

- The theoretical calculation is very complicated and far from actual result. In general, the manufacturer knows how much area and how thick their products can be painted.

- Q: I have a 94 Gt Mustang that has had a little work done to it so far. The boy I bought it from had an aftermarket cam put in it, had the heads ported and polished. He also had the heads shaved a little. My question is.........Would having aluminum heads with roller rocker arms installed help it enough to justify doing it. If it would, how Much would it help? I am not exactly sure how much life and duration my cam is running, but it idle pretty rough. I believe my compression is about 9.5 to 1.

- Well using aluminum heads would be enough to justify doing it because i have aluminum heads and im at 11:1 compression. These heads are 9.5:1 compression with 11:1 compression with twin turbos. Now you are running with straight motor and shoud be fine. Now if you are going to get that pony a supercharger I would suggest getting cast iron heads with a chrome finish to manage this power gain. I have had these for about 40K miles and are still fine. I will eventually change to cast iron with a chrome finish. Hope this helps.

- Q: This question asks about the current market demand for aluminum coil, which is a versatile material used in various industries.

- <p>The market demand for aluminum coil is significant and growing due to its wide range of applications across industries such as construction, automotive, aerospace, packaging, and electronics. Its lightweight, corrosion resistance, and recyclability make it a preferred material for many applications. The demand is influenced by economic growth, technological advancements, and sustainability initiatives. As countries focus on greener construction and manufacturing processes, the demand for aluminum coil is expected to increase further.</p>

- Q: How do aluminum coils compare to copper coils in terms of performance?

- Aluminum coils and copper coils are two common types of heat exchanger coils used in heating, ventilation, and air conditioning (HVAC) systems. While both materials are effective in transferring heat, they do differ in terms of performance. Copper coils have long been the preferred choice for HVAC systems due to their superior heat transfer properties. Copper is an excellent conductor of heat, allowing for efficient transfer of thermal energy. This means that copper coils can cool or heat the surrounding air more effectively, resulting in faster and more efficient temperature control. On the other hand, aluminum coils are less efficient in terms of heat transfer compared to copper coils. Aluminum is a poorer conductor of heat, which means that it requires a larger surface area to achieve the same level of heat transfer as copper. Consequently, aluminum coils tend to be larger in size to compensate for their lower heat transfer capabilities. However, aluminum coils do have some advantages over copper coils. Firstly, aluminum is a lightweight material, making it easier to handle and install. This can be particularly beneficial in situations where weight restrictions or handling limitations are a concern. Secondly, aluminum coils are more resistant to corrosion compared to copper coils. Copper is prone to corrosion over time, especially in environments with high humidity or exposure to certain chemicals. Aluminum, on the other hand, naturally forms a protective oxide layer that helps prevent corrosion. This can result in longer-lasting coils and a lower likelihood of refrigerant leaks. In summary, while copper coils offer superior heat transfer capabilities, aluminum coils have their own advantages such as lighter weight and better corrosion resistance. The choice between aluminum and copper coils ultimately depends on the specific requirements of the HVAC system, including the desired performance, budget, and environmental factors.

- Q: Are aluminum coils suitable for food and beverage packaging?

- Yes, aluminum coils are suitable for food and beverage packaging. Aluminum is a versatile material that offers various advantages for packaging applications. It is lightweight, making it easy to transport and handle. Aluminum is also highly resistant to corrosion, which ensures that the packaging remains intact and protects the contents from external factors. Additionally, aluminum has excellent thermal conductivity, allowing for efficient heat transfer, which is beneficial for food and beverage products that require temperature control. It is also impermeable to light, moisture, and oxygen, providing an excellent barrier to maintain the quality and freshness of the packaged items. Furthermore, aluminum is recyclable and can be reused, making it an environmentally friendly choice for packaging. Overall, aluminum coils are a reliable and suitable option for food and beverage packaging due to their durability, protective properties, and sustainability.

- Q: Are aluminum coils suitable for automotive body panels?

- Indeed, automotive body panels can be effectively constructed using aluminum coils. The lightweight nature of aluminum greatly contributes to enhancing fuel efficiency and overall vehicle performance. Furthermore, the exceptional corrosion resistance of aluminum makes it an optimal selection for automotive applications, particularly when the panels are frequently subjected to diverse weather conditions. The impressive strength-to-weight ratio of aluminum further ensures outstanding durability and crash resistance. Moreover, aluminum allows for effortless formation and shaping, enabling the creation of intricate and fashionable designs. In conclusion, the utilization of aluminum coils for automotive body panels presents a multitude of benefits, making it a highly favored option for car manufacturers.

Send your message to us

Alcoa Aluminum Coil Primrose Yellow Coated Sheet Metal Roofing Material

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t.

- Supply Capability:

- 200 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords