Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Grain Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Wooden Grain Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Grain Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

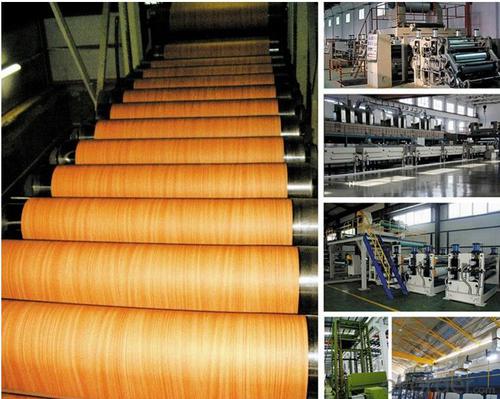

5. Image of Wooden Grain Coating Aluminum Coil with High Quality

6. Package and shipping of Wooden Grain Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: Aluminum extrusions are bars made with hollow cavities that allow each to be joined easily, using special connectors. The primary difficulty when painting aluminum extrusions centers on the fact that they are nonporous and durable. Each of these traits creates a complication of its own.

- Your question supposes that you need to Paint the Aluminum Extrusion. The more common thing to do is to Anodize the extrusion. This process coats all surfaces with a hard durable coating. There are several colors available. Actually It's common to use Urethane's to paint Aluminum and the primer isn't simply made for metal, but is specifically for Aluminum. A lot of Airplanes are coated every day in this manner. Methods for coating the insides of tubing have been used for a very long time. You basically fill the tube with primer or coating then drain the excess out (dip method) and difficult shapes can be powder coated or electro static coated. Extrusions can be roller coated after cleaning, vinyls work very well with out priming. Think Toothpaste tubes.

- Q: Hey everybody I'm trying to improve the performance of my vintage metal Coleman cooler I just got. To test it I filled it up with water bottles and 5lbs of cubed ice from Stop and Shop and left it in the closet with the dorm's AC set to 65. When I got back 28 hours later the ice was completely melted. The water still kept the drinks cool for several days after that, but I'm frustrated that the ice melted in a single day.

- It's perfect if you are just starting out or if you're a seasoned carpenter. you will like it for sure ! It has almost 20.000 woodworking plans and you have a CAD/DWG software to view and edit the plans. You have step-by-step instructions with photos and high quality blueprints and schematics. If you are a beginner this is the easiest way to start your woodworking projects, and if you already have experience you can anyway find a lot of interesting ideas!

- Q: Explain how aluminum coils function to shield against electromagnetic interference.

- <p>Aluminum coils protect against electromagnetic interference (EMI) through a process known as electromagnetic shielding. Aluminum, being a conductive material, can reflect and absorb EMI, preventing it from penetrating the protected area. When an aluminum coil is used as a shield, it creates an electric field that interacts with the EMI, either reflecting the interference back or absorbing it, thus reducing its impact on sensitive electronic equipment. The high conductivity of aluminum also allows it to distribute the EMI evenly across its surface, minimizing the effect of any single point of entry. This shielding is crucial in various applications, such as in electronic devices and communication systems, to ensure reliable performance and data integrity.</p>

- Q: What is the typical coefficient of friction for aluminum coils?

- The coefficient of friction for aluminum coils can differ based on numerous factors, including surface conditions, lubrication, and the specific aluminum alloy employed. Nevertheless, compared to other materials, aluminum coils generally exhibit a relatively low coefficient of friction. Typically, it ranges from 0.1 to 0.4.

- Q: What are the different coil coating options available for aluminum coils?

- There are several different coil coating options available for aluminum coils, each offering unique benefits and properties. 1. Polyester: Polyester coil coating is a popular choice due to its durability and cost-effectiveness. It provides good resistance to weathering, UV rays, and chemical exposure. Polyester coatings are available in a wide range of colors and finishes, making them suitable for various aesthetic applications. 2. Polyvinylidene Fluoride (PVDF): PVDF coatings offer superior durability and resistance to UV rays, weathering, and chemicals. They have excellent color retention and can withstand harsh environmental conditions. PVDF coatings are commonly used in architectural applications where long-term durability and aesthetics are critical. 3. Polyurethane: Polyurethane coil coatings provide excellent adhesion, flexibility, and impact resistance. They are known for their high gloss and vibrant colors. Polyurethane coatings are often used in applications requiring superior resistance to abrasion, such as appliances and automotive components. 4. Epoxy: Epoxy coil coatings offer excellent corrosion resistance and adhesion properties. They are commonly used in industrial applications where protection against chemicals and harsh environments is required. Epoxy coatings can be applied as a primer or a topcoat, depending on the specific requirements. 5. Acrylic: Acrylic coil coatings provide good weather resistance, color retention, and gloss. They are often used in outdoor applications where exposure to UV rays and environmental conditions is a concern. Acrylic coatings can be formulated to achieve different levels of durability and flexibility. 6. Silicone Modified Polyester (SMP): SMP coil coatings combine the benefits of polyester and silicone, offering enhanced weather resistance and durability. They provide excellent color retention, gloss retention, and resistance to chalking. SMP coatings are commonly used in architectural and industrial applications. It is important to consider the specific requirements of the application, including durability, aesthetics, and environmental conditions, when selecting the appropriate coil coating option for aluminum coils. Consulting with a coil coating expert can help determine the best option based on the desired performance and appearance.

- Q: This question asks about the environmental impact of aluminum coils, which are commonly used in various industries.

- <p>Aluminum coils have both positive and negative environmental impacts. On the positive side, aluminum is highly recyclable, and its use in coils reduces the need for raw material extraction, thus conserving natural resources. The recycling process also consumes less energy compared to primary aluminum production, reducing greenhouse gas emissions. However, the production of aluminum coils involves energy-intensive processes that can contribute to carbon emissions. Additionally, if not properly managed, the waste from aluminum production can pollute water bodies and soil. Overall, the environmental impact depends on the balance between recycling and production practices, as well as waste management.</p>

- Q: How are aluminum coils used in the production of heat sinks?

- Aluminum coils play a vital role in the production of heat sinks due to their excellent thermal conductivity and malleability. Heat sinks are designed to dissipate the excess heat generated by electronic components such as processors, integrated circuits, and power transistors. By utilizing aluminum coils in the manufacturing process of heat sinks, several key advantages are realized. Firstly, aluminum coils possess high thermal conductivity, which allows for efficient transfer of heat from the electronic component to the heat sink. This is crucial for maintaining the optimal operating temperature of the electronic device, as excess heat can cause performance degradation and even permanent damage. The high thermal conductivity of aluminum ensures that the heat is rapidly dissipated away from the electronic component, preventing overheating. Secondly, aluminum coils are highly malleable, making them easy to shape and mold into various designs required for heat sinks. Heat sinks are available in different sizes and shapes, with the most common being finned heat sinks. The fins on the heat sink increase the surface area, allowing for greater heat dissipation. Aluminum coils can be easily formed into these fin shapes, enabling the heat sink to effectively release heat into the surrounding environment. Additionally, aluminum coils are lightweight and corrosion-resistant, making them ideal for use in heat sinks. The lightweight nature of aluminum ensures that the heat sink does not add significant weight to the electronic device, which is especially important in applications where weight restrictions are crucial, such as aerospace or portable electronics. Moreover, the corrosion-resistant properties of aluminum ensure the longevity and durability of the heat sink, even in harsh environments. In conclusion, aluminum coils are essential components in the production of heat sinks due to their high thermal conductivity, malleability, lightweight, and corrosion-resistant properties. By incorporating aluminum coils into the manufacturing process of heat sinks, efficient heat dissipation and improved performance of electronic components can be achieved, ultimately prolonging the lifespan of electronic devices.

- Q: How do aluminum coils perform in corrosive environments?

- Due to their inherent properties and protective coatings, aluminum coils exhibit exceptional performance in corrosive environments. When exposed to air, aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against corrosion. This oxide layer displays high resistance to various corrosive agents, including saltwater, acids, and atmospheric pollutants. Moreover, aluminum coils can receive additional protection through diverse coatings and treatments, further enhancing their resistance to corrosion. These protective coatings can be organic, such as paint or lacquer, or inorganic, like anodizing or chemical conversion coatings. The combination of aluminum's natural oxide layer and supplementary protective coatings makes aluminum coils highly reliable and durable in corrosive environments. This corrosion resistance is especially advantageous in industries such as marine, chemical processing, and coastal applications, where exposure to saltwater or aggressive chemicals is commonplace. In addition, aluminum coils are lightweight, contributing to their versatility and ease of installation, making them suitable for a wide range of corrosive environments. This lightweight property also aids in reducing transportation costs and energy consumption during the installation process. In conclusion, aluminum coils are well-suited for corrosive environments due to their inherent corrosion resistance and the availability of protective coatings. Their durability, lightweight nature, and resistance to corrosion make them the ideal choice for numerous industries and applications, where longevity and performance are essential considerations.

- Q: What are the applications of aluminum coils?

- Due to their unique properties and versatility, aluminum coils find wide-ranging applications in various industries. The construction industry is one major field where these coils are extensively used. They are lightweight, durable, and resistant to corrosion, making them suitable for roofing, siding, and insulation purposes. Additionally, aluminum coils are commonly employed in the production of gutters, downspouts, and ventilation systems for buildings. In the automotive sector, aluminum coils are utilized for manufacturing different components like heat shields, radiators, and condensers. The lightweight nature of aluminum makes it an ideal choice for enhancing fuel efficiency and reducing the overall weight of vehicles. Moreover, aluminum coils are employed in the production of heat exchangers and air conditioning systems in automobiles. The packaging industry also heavily relies on aluminum coils. They are commonly used to manufacture beverage cans, food containers, and packaging materials. Aluminum's high ductility and excellent formability make it a preferred material for producing these products. Additionally, aluminum coils act as a barrier against moisture, light, and oxygen, ensuring the preservation and protection of the packaged contents. In the electrical and electronics industry, aluminum coils find a crucial application. They are utilized in the production of transformers, power distribution systems, and electrical conductors. The high electrical conductivity and low density of aluminum make it advantageous for these purposes. Furthermore, aluminum coils are employed in the manufacturing of appliances such as refrigerators, air conditioners, and washing machines. They are also utilized in the production of furniture, decorative items, and various consumer goods. In conclusion, aluminum coils have vast and diverse applications in industries ranging from construction and automotive to packaging, electrical, and consumer goods. The combination of lightweight, durability, corrosion resistance, and excellent formability make aluminum coils an indispensable material in numerous sectors.

- Q: What are the different protective film options for aluminum coils?

- There are several protective film options available for aluminum coils, each offering specific benefits and suitability for different applications. Some common options include: 1. PVC (Polyvinyl Chloride) Film: PVC films are widely used for protecting aluminum coils due to their excellent resistance to moisture, chemicals, and abrasion. They provide a high level of surface protection and are available in various thicknesses and adhesive strengths. 2. PE (Polyethylene) Film: PE films are another popular choice for protecting aluminum coils. They offer good resistance to moisture and UV radiation and are generally more cost-effective than PVC films. PE films are available in different grades, including low-density polyethylene (LDPE) and linear low-density polyethylene (LLDPE). 3. PP (Polypropylene) Film: PP films are known for their excellent tear resistance and high tensile strength. They provide good protection against mechanical damage and are suitable for applications where coils may undergo rough handling or transportation. 4. PET (Polyethylene Terephthalate) Film: PET films offer outstanding clarity and transparency, making them ideal for applications where visual inspection of the coils is required. They also provide good resistance to heat, chemicals, and abrasion. 5. Adhesive Coatings: In addition to films, adhesive coatings are sometimes used to protect aluminum coils. These coatings are typically applied directly to the surface of the coil and form a protective layer against moisture, corrosion, and scratching. When selecting a protective film for aluminum coils, it is essential to consider factors such as the intended application, environmental conditions, handling processes, and desired level of protection. Consulting with a supplier or manufacturer can help determine the most suitable option for specific requirements.

Send your message to us

Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords