Wholesale Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coil for Casting:

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Coil for Casting

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

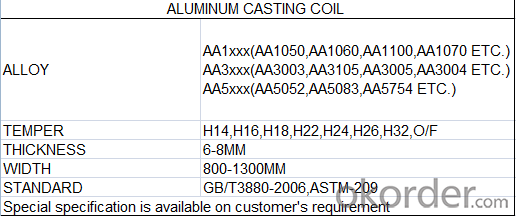

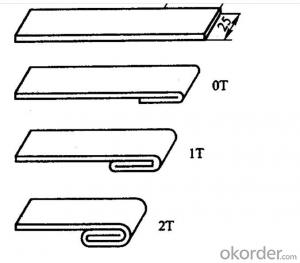

3. Aluminum Coil for Casting

4. Aluminum Coil for Casting

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Coil for Casting

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q: Can aluminum coils be used in solar panel installations?

- Indeed, solar panel installations can make use of aluminum coils. The lightweight properties, corrosion resistance, and remarkable thermal conductivity of aluminum make it a favored material for constructing solar panels. Frequently, aluminum coils are employed as the supportive backing material for solar panels, ensuring both structural stability and effective heat dissipation. Additionally, these coils are commonly utilized in the production of solar mounting systems, which securely hold the panels in position. All in all, aluminum coils present a dependable and efficient choice for solar panel installations.

- Q: Can aluminum coils be used in the production of heat exchangers?

- Indeed, the utilization of aluminum coils in the fabrication of heat exchangers is feasible. Aluminum has gained significant popularity as a preferred material for heat exchangers owing to its exceptional thermal conductivity, which facilitates effective heat transfer. Moreover, its lightweight nature and resistance to corrosion render it a durable and enduring choice for heat exchanger implementations. The incorporation of aluminum coils in heat exchangers is widespread across diverse sectors such as HVAC, refrigeration, automotive, and aerospace.

- Q: How does aluminum ingot be processed to aluminum coil (aluminum sheet)?

- First it should be made into blank and then put on the rolling mill.

- Q: What are the tensile strength properties of aluminum coils?

- The tensile strength properties of aluminum coils can vary depending on the specific alloy and temper of the aluminum. Generally, aluminum has a good tensile strength, ranging from 70 to 700 MPa (megapascals). The specific tensile strength of aluminum coils can be determined through material testing and analysis.

- Q: How do aluminum coils perform in high-temperature applications?

- Aluminum coils perform exceptionally well in high-temperature applications. Aluminum is known for its excellent heat conductivity and high melting point, allowing it to withstand extreme temperatures without losing its structural integrity. This makes aluminum coils a popular choice for various industries that require heat transfer and dissipation, such as automotive, aerospace, and HVAC systems. One of the key advantages of aluminum coils in high-temperature applications is their ability to efficiently transfer heat. Aluminum has a thermal conductivity that is much higher than other commonly used metals, such as copper or steel. This means that aluminum coils can quickly and effectively transfer heat from one area to another, ensuring efficient heat dissipation and preventing overheating. Additionally, aluminum has a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit), which is significantly higher than many other metals. This allows aluminum coils to withstand high temperatures without deforming, warping, or losing their structural integrity. Their stability at high temperatures makes them suitable for applications where heat resistance is crucial, such as in engine cooling systems or industrial ovens. Furthermore, aluminum coils are lightweight compared to other metals, which is another advantage in high-temperature applications. Their low density allows for easier handling and installation, reducing the overall weight of the system. This is particularly important in industries like automotive and aerospace, where weight reduction is a significant factor for improving fuel efficiency and overall performance. In summary, aluminum coils are highly reliable and perform exceptionally well in high-temperature applications. Their excellent heat conductivity, high melting point, and lightweight properties make them an ideal choice for industries that require efficient heat transfer, heat dissipation, and heat resistance.

- Q: helicopters rotorblades are made of honeycombed aluminum to give them strength, so isn't it a good idea for automakers to use the same technology to strengthen the frames of autos to make them lesslikely to cave in during a side impact auto accident?

- hmm, so if a helicopter rotor collided with say a tree, you think the rotor would survive?

- Q: Can aluminum coils be used for electrical applications?

- Yes, aluminum coils can be used for electrical applications. Aluminum is a widely used material in the electrical industry due to its excellent conductivity, lightweight properties, and corrosion resistance. Aluminum coils are commonly used in various electrical applications such as transformers, motors, generators, and coils for inductors and solenoids. They offer advantages such as high thermal conductivity and low eddy current losses, making them efficient in transferring and distributing electrical power. Additionally, aluminum coils are cost-effective compared to copper coils, making them a preferred choice for many electrical applications. However, it is important to note that aluminum has a lower electrical conductivity compared to copper, so the coil design and dimensions may need to be adjusted accordingly to ensure optimal performance.

- Q: How are aluminum coils used in insulation applications?

- Aluminum coils are commonly used in insulation applications as they are lightweight, durable, and have excellent thermal conductivity properties. They are typically used to create a radiant barrier or reflective insulation, where they are installed between the outer walls or roofs of a building and the insulation material. The reflective surface of the aluminum coil helps to reflect radiant heat away from the building, reducing heat transfer and improving energy efficiency. Additionally, aluminum coils are also used in HVAC systems to create air ducts that ensure proper insulation and prevent heat loss or gain.

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- when this phenomenon occurs in feeding occurs when you say the phenomenon, when parking tension shock or mutation, the inner drum contraction material, inner sleeve trace diameter decreases, emergency stop when the inertia torque increase, will influence on the oil film, and is the inner bag sleeve is not tight, causing the inner diameter decreases due to aluminum transfer from the inner ring to slide staggered, outer ring, the outer ring can be transferred to the volume of the material into a neat is not neat, not fully delivered appeared loose layer.

- Q: What precautions should be taken when handling aluminum coils to ensure safety?

- <p>When using aluminum coils, safety measures include wearing appropriate personal protective equipment such as gloves and safety glasses to prevent cuts and eye injuries. Ensure the work area is well-ventilated to avoid inhaling fumes from any processes involving the coils. Keep the coils dry to prevent electrical hazards. Use proper handling equipment to avoid back injuries from heavy loads. Always follow the manufacturer's guidelines for the specific aluminum coil products being used. Regularly inspect the coils for any signs of damage or wear that could lead to accidents.</p>

Send your message to us

Wholesale Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords