Wholesale Mill Finish Aluminum Roof Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Alloy | AA1100, AA3003, AA3005, AA3105, AA8011 |

Temper | H16-18, H46 |

Thickness | 0.15mm – 1.0mm |

Width | 900mm – 1600mm |

Length | 200m – 2000m |

Chemical Composition (WT %)

| Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Others | Rem. Al |

AA1100 | 0.116 | 0.478 | 0.069 | / | / | / | / | / | / | / | 99.70 |

AA3003 H16-18 | 0.59 | 0.66 | 0.01 | 0.32 | 0.21 | Tr | Tr | Tr | 0.02 | Tr | 98.15 |

AA3003 H46 | 0.6 | 0.7 | 0.05-0.20 | 1.0-1.5 | / | / | / | 0.10 | / | 0.20 | 97.02 |

AA3005 | 0.6 | 0.7 | 0.3 | 1.0-1.5 | 0.2-0.6 | 0.10 | / | 0.25 | 0.10 | 0.20 | 96.10 |

AA3105 | 0.6 | 0.7 | 0.3 | 0.3-0.8 | 0.2-0.8 | 0.20 | / | 0.40 | 0.10 | 0.20 | 96.45 |

AA8011 | 0.5-0.9 | 0.6-1.0 | 0.10 | 0.20 | 0.05 | 0.05 | / | 0.10 | 0.08 | 0.20 | 97.72 |

Mechanical Properties

| 0.2% Proof stress (Kg/Sqmm) | Ultimate tensile strength (MPa) | % Elongation | Bend test (180 Degree) | % Earing | Depth height (mm) |

AA1100 H16-18 | NA | 150-180 | 2.00 | NA | NA | NA |

AA3003 H16-18 | NA | 178.4 | 3.00 | NA | NA | NA |

AA3003 H46 | 165-205 | >145 | ≥1 | NA | NA | NA |

AA3005 H46 | NA | 195-250 | >180 | > 2 | NA | NA |

AA3105 H46 | 175-225 | >145 | ≥1 | NA | NA | NA |

AA8011 H16-18 | NA | 145-180 | 1.00 | NA | NA | NA |

Embossed color coatedaluminum coil

the company can produce the aluminum coil pattern are: classic orange peel pattern,and variation orange peel pattern (also called as bugs’ pattern). Thicknessspecification is 0.2mm ~ 0.6mm, width less than 1600mm. The materials used arefluorocarbon coated aluminum, polyester coated aluminum coil, aluminum roll,light aluminum, brushed aluminum rolls.

By embossing the surface of aluminum coil elegant, streamlined good, solidsense. Embossed aluminum coil aluminum coil can not only increase the thicknessof the aluminum coil thickness of 0.1 ~ 0.25mm. At the same time can enhance thestrength of aluminum coil, stiffness, and does not affect the original surfacelayer of the aluminum coil with the performance.

Embossed aluminum coil, wide range of uses. Mainly used for indoor and outdoordecoration, freezer, refrigerator, decorative aluminum products, bags, centralair conditioning and ventilation nozzles, and mechanical equipment enclosuresand so on. Is a new decorative material.

Thecompany has two production lines embossed aluminum coil: one for the simpleformula: put through Unwinder mechanical embossing roll winder windingembossed, convenient and quick. Another is the compound: that is embosseddirectly into the device placed in the coating line, coating and embossingsynchronization, when the coating needs of embossed aluminum coil, through thehydraulic transmission, the embossing machine, under the pressure rollerengagement, aluminum coating line directly in the embossing roll, fast, lowcost, no turnover.

Thickness range

0.2mm—0.6mm

Width range

800mm—1590mm

Technical parameters

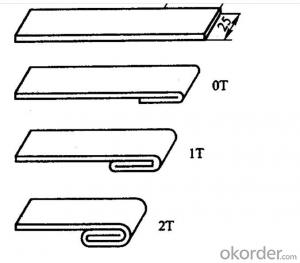

Aluminum thickness | Coating thickness | MEK | T-bend | Impact | Adhesion | Pencil hardness | Boiling water proof |

0.20-0.60mm | ≥18±1um | ≥100times | ≤3T | 50kg.cm | 0grade | ≥HB | no change within 2 hours |

Performance and Application

Embossed aluminum coil for roofing is coatedwith high-performance polyester paints. And its each performance index is up toor exceeds the national standard. With its glorious colors, little chromatism,strong impact and easy machinability, the product serves as a premium materialin roofing, electric appliances, etc.

- Q: Are aluminum coils suitable for HVAC systems?

- Indeed, HVAC systems can utilize aluminum coils as they prove to be a suitable choice. When compared to conventional copper coils, aluminum coils present numerous advantages. Notably, their heightened resistance to corrosion aids in prolonging the lifespan of the HVAC system. Moreover, aluminum coils possess superior heat transfer properties, facilitating more efficient cooling and heating processes. Additionally, their lighter weight allows for effortless installation and manageable handling during maintenance or repairs. Consequently, aluminum coils emerge as a dependable and cost-effective alternative for HVAC systems.

- Q: What are the common alloys used in aluminum coil production?

- The common alloys used in aluminum coil production are 3003, 3105, 5052, and 6061.

- Q: What are the different surface finishes available for aluminum coils?

- There are several different surface finishes available for aluminum coils, including mill finish, brushed finish, embossed finish, anodized finish, and painted finish.

- Q: What are the uses of aluminum coils?

- Aluminum coils have a wide range of uses across various industries. One of the primary uses of aluminum coils is in the manufacturing of HVAC systems and air conditioning units. The coils are used to transfer heat and cool air, making them essential components in these systems. Additionally, aluminum coils are also commonly used in the construction industry for roofing, cladding, and insulation purposes. They are lightweight, durable, and resistant to corrosion, making them ideal for outdoor applications. The automotive industry also utilizes aluminum coils in the production of vehicles. They are used in the manufacturing of various parts, including radiators, heat exchangers, and condensers, due to their excellent heat transfer properties. Aluminum coils are also extensively used in the packaging industry. They are used to produce cans and containers for food and beverages. Aluminum is a great choice for packaging as it is lightweight, recyclable, and provides a barrier against moisture, oxygen, and light, ensuring the quality and freshness of the enclosed products. Furthermore, aluminum coils find applications in electrical wiring, where they are used as conductors due to their high electrical conductivity. They are also used in the production of electronics, such as laptops, smartphones, and tablets, as they offer excellent heat dissipation properties. Overall, the uses of aluminum coils are diverse and varied, ranging from HVAC systems and construction to automotive, packaging, and electrical applications. The versatility, durability, and excellent properties of aluminum make it a preferred material choice in many industries.

- Q: What is the minimum width of aluminum coils?

- The minimum width of aluminum coils can vary depending on the specific requirements and manufacturing capabilities, but it is typically around 0.5 inches or 12.7 millimeters.

- Q: Can aluminum coils be used for electrical enclosures?

- Electrical enclosures can indeed utilize aluminum coils. Aluminum, being a lightweight and durable substance, boasts exceptional electrical conductivity and heat dissipation capabilities. Furthermore, it exhibits commendable resistance to corrosion, rendering it appropriate for diverse environmental circumstances. Due to its malleability, aluminum coils effortlessly adopt various shapes and sizes, rendering them highly adaptable for enclosure designs. Moreover, aluminum represents a cost-effective alternative when compared to metals such as stainless steel. Nonetheless, it remains crucial to guarantee adequate insulation and grounding to avert any potential electrical hazards when employing aluminum coils in electrical enclosures.

- Q: Roll presented above 1 complete circles are brineling put on work roll after the new rolling, less than 12 volumes in the aluminum surface will be presented in the corresponding position of a straight roller, a roller indentation in the above, check the work roll above a pit. Replace the upper support roll for only a few days. Want to know what's going on?Should not be bearing problems, because the bearings have been used for almost 4 years, it should not be bearing problems, and now they are suspected of bending cylinder seal problems, oil seepage phenomenon.

- For a few days and roll crushed?Whether or not the work roll tilt and the positive and negative camber of the roll are controlled, the work roll is running abnormally, and the backup roller is rubbed.

- Q: Are aluminum coils suitable for heat sinks?

- Yes, aluminum coils are suitable for heat sinks. Aluminum is a popular choice for heat sinks due to its excellent thermal conductivity and low cost. The high thermal conductivity of aluminum allows it to efficiently transfer heat away from a heat source towards the fins of the heat sink, where it can be dissipated into the surrounding environment. Additionally, aluminum is lightweight and easily formed into various shapes, making it a versatile material for heat sink applications. Overall, aluminum coils are a suitable choice for heat sinks, providing effective heat dissipation and cost-effectiveness.

- Q: What are the typical thickness tolerances for aluminum coils?

- The typical thickness tolerances for aluminum coils depend on the specific application and industry standards. However, in general, the thickness tolerances for aluminum coils can range from +/- 0.002 inches to +/- 0.005 inches.

- Q: Explain the distinctions among various types of aluminum coils, including their properties and applications.

- <p>Aluminum coils are differentiated based on their alloy composition, thickness, temper, and surface finish. Common types include 1000 series coils, which are pure aluminum with high ductility but low strength; 3000 series, known for their formability and used in cookware; 5000 series, which are non-heat-treatable and corrosion-resistant; and 6000 series, offering a balance of strength and corrosion resistance. Thickness varies from thin gauges for flexible applications to thick gauges for structural use. Tempers range from soft (O temper) to fully hard (H temper), affecting the coil's hardness and strength. Surface finishes can be plain, coated, or embossed, impacting aesthetics and performance. Each type is chosen based on specific industry requirements like construction, automotive, or packaging.</p>

Send your message to us

Wholesale Mill Finish Aluminum Roof Coils

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords