Aluminum 3xxx Quality D.C. Aluminum Circles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Circles D.C Quality 3XXX Description

Aluminum Circles D.C Quality 3XXX is made from aluminum coils 3xxx.Aluminum circles D.C quality 3XXX has great ductility, heat conductivity, anti-corrosion and moisture resistance properties.

Aluminum Circles D.C Quality 3XXX are widely used for kitchen wares including fried pans, non-sticky pans, cooking pots,hard anodized cookware, pressure cooker and house hold utensils.

2.Main Features of the Aluminum Circles D.C Quality 3XXX

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

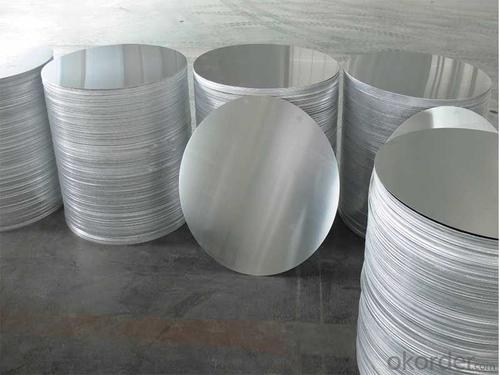

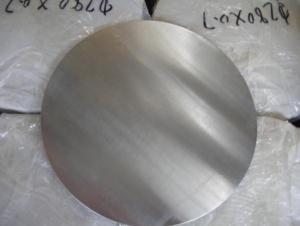

3.Aluminum Circles D.C Quality 3XXX Images

4.Aluminum Circles D.C Quality 3XXX Specification

| Alloy | AA3xxx (AA3003 etc) |

| Temper | O.H14 |

| Thickness | 0.5mm-4mm |

| Diagonal | 100mm-1200mm |

| Standard | GB/T 3880-2006 |

5. FAQ of Aluminum Circles D.C Quality 3XXX

A.When will you deliver the products?

The aluminum aluminum sheets 1xxx C.C quality will be delivered within 35 days after receiving advanced payment or original L/C.

B. Now which countries do you export your goods?

Now we export to South East Asia,Africa, North America,South America ect.

- Q: Is it possible to recycle old aluminum products and what are the benefits of doing so?

- <p>Yes, old aluminum products can be recycled. Recycling aluminum is highly beneficial as it conserves resources, saves energy, and reduces waste. The process of recycling aluminum requires only 5% of the energy needed to produce new aluminum from raw materials, making it an environmentally friendly option. Additionally, recycling helps to decrease the amount of aluminum that ends up in landfills, thus reducing the environmental impact of mining and processing new aluminum.</p>

- Q: What measures should be taken to ensure safety when handling or using aluminum products?

- <p>When using aluminum products, safety precautions include handling with care to avoid sharp edges that may cause cuts. Ensure proper ventilation when working with aluminum powder or dust to prevent respiratory issues or fire hazards. Avoid using aluminum cookware for acidic or alkaline foods as it can react and leach aluminum into the food. Always follow the manufacturer's instructions for use and cleaning, and wear appropriate protective gear such as gloves and masks when necessary.</p>

- Q: Is it possible for aluminum to penetrate the skin and be absorbed into the body?

- <p>Aluminum can be absorbed through the skin, but the rate and extent of absorption are generally low. The skin acts as a barrier and only allows minimal absorption of aluminum. Most aluminum exposure comes from ingestion, not dermal absorption. The body's ability to absorb aluminum can be influenced by factors such as the form of aluminum, the condition of the skin, and the duration of exposure. However, it's important to note that aluminum is commonly found in everyday products and is generally considered safe in the amounts typically encountered.</p>

- Q: This question asks for a comparison between aluminum and other metals, highlighting their distinct properties and characteristics.

- <p>Aluminum is a lightweight, corrosion-resistant metal with a low density, making it ideal for applications requiring strength without excessive weight. It is also a good conductor of heat and electricity. Unlike other metals like iron or copper, aluminum is not magnetic and has a lower melting point. It is also more abundant and cheaper to produce than many other metals, which makes it widely used in industries such as construction, transportation, and packaging. Aluminum's reactivity means it forms a protective oxide layer when exposed to air, which prevents further corrosion. In contrast, metals like stainless steel offer greater strength and resistance to corrosion, while copper has superior electrical conductivity. Each metal has its unique properties that make it suitable for specific applications.</p>

- Q: This question asks about the process through which aluminum deteriorates over time due to environmental factors.

- <p>Aluminum corrodes through a process called oxidation. When exposed to air, aluminum reacts with oxygen to form a thin, protective layer of aluminum oxide on its surface. This layer prevents further corrosion. However, in the presence of moisture, acids, or other corrosive substances, the aluminum oxide layer can break down, leading to further oxidation and eventual pitting or thinning of the aluminum. The rate of corrosion can be influenced by factors such as temperature, humidity, and the presence of impurities in the aluminum. Proper protective measures, such as coatings or anodizing, can help prevent or slow down the corrosion process.</p>

- Q: This question asks for various methods that can be used to recycle aluminum.

- <p>Recycling aluminum can be done through several methods, including mechanical recycling, which involves melting and reprocessing aluminum without altering its chemical properties. This is the most common method due to its efficiency and cost-effectiveness. Another method is chemical recycling, where aluminum is treated with chemicals to break it down into its constituent elements, which can then be repurposed. Additionally, aluminum can be recycled through a process called hydrometallurgical recycling, which uses aqueous solutions to extract aluminum from waste. Finally, sorting and collection play a crucial role in ensuring that aluminum waste is directed to appropriate recycling facilities where these methods can be applied.</p>

- Q: Describe the process of electrolysis used in aluminum production.

- <p>The process of electrolysis for aluminum production involves the Hall-H茅roult process, which is the primary method for extracting aluminum from its ore, bauxite. First, bauxite is refined to produce aluminum oxide (alumina). This alumina is then dissolved in a molten cryolite bath, which lowers the melting point and increases the electrical conductivity. Large amounts of electricity are passed through the bath, causing the alumina to decompose into aluminum metal and oxygen gas. The aluminum collects at the bottom of the cell and is periodically tapped off, while the oxygen is released into the atmosphere. This energy-intensive process is crucial for the aluminum industry, as it allows for the production of large quantities of aluminum, a key material in various industries.</p>

- Q: Can recycled aluminum be utilized in the production of solar panels and other renewable energy technologies?

- <p>Yes, recycled aluminum can be used to make solar panels and other renewable energy sources. Aluminum is a key component in solar panel frames and mounting structures due to its lightweight, high strength, and corrosion resistance. Recycling aluminum saves energy and resources compared to mining and refining new aluminum. Additionally, recycled aluminum can be used in wind turbines, hydroelectric generators, and other renewable energy technologies where its properties are beneficial. The use of recycled materials in renewable energy production contributes to a more sustainable and circular economy.</p>

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

Send your message to us

Aluminum 3xxx Quality D.C. Aluminum Circles

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches