D.C Quality Aluminum Circles for Cookware 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

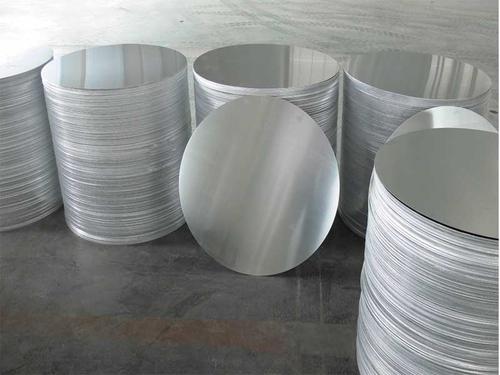

1.Structure of D.C Quality Aluminum Circles for Cookware 1XXX

D.C Quality Aluminum Circles for Cookware 1XXX is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of D.C Quality Aluminum Circles for Cookware 1XXX

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

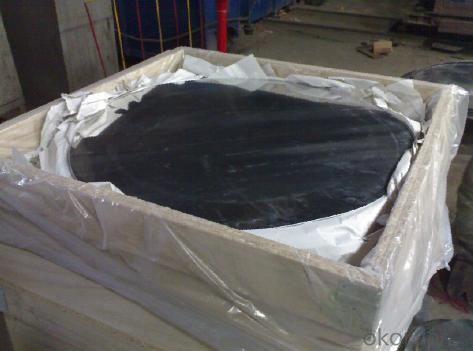

3. Image of D.C Quality Aluminum Circles for Cookware 1XXX

4. Product Specification of D.C Quality Aluminum Circles for Cookware 1XXX

| ALLOY | TEMPER | THICKNESS | DIAMETER | FINAL USAGE |

| AA5052 | H18 | 0.2MM-3MM | 100MM-1000MM | POT |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

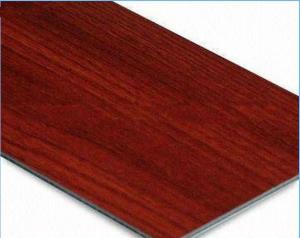

- Q: What are the differences between fire-resistant aluminum-plastic panels and ordinary aluminum-plastic plates? What are the standards for fire protection on aluminum flooring for business premises?

- In other words purely from the fire level, said the fire aluminum (plastic) composite board at least the corresponding level is B,

- Q: How to open the aluminum plate

- Aluminum-plastic plate openings will crack, then it is not called aluminum-plastic plate, or is defective defective

- Q: Do you have a board on the back of an aluminum - plastic panel for exterior decoration and advertising

- You can be other materials, do billboards, the purpose is to save some money!

- Q: OKorder side there is no production of new materials, aluminum-plastic plate manufacturers? I want to use the pillars, the need to process the arc, very anxious to solve!

- I am not in OKorder in Kunming, do not know useful to you! The last time I do in Liupanshui do gas station is also need to pack pillars, Party is also required to use new materials, aluminum-plastic plate, I find a long time did not find, and later from Kunming cloud like building materials, anyway, OKorder is not here from us Far, useful words remember to adopt! Thank you

- Q: What are the specifications of the aluminum-plastic plate? What are the aluminum-plastic board manufacturers?

- Aluminum plate specifications a lot, you can also order, the main specifications are 1220X2440X4mm; 1220X2440X3mm

- Q: Want to collect OKorder aluminum veneer aluminum curtain wall more curtain wall company, thank you! Will be thank you!

- Can be said that the specific point is not with the OCT Jellyfish that the same

- Q: Will the aluminum plate can make a wardrobe?

- Aluminum-plastic composite board is a chemically treated coated aluminum sheet for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials. The unique performance of the aluminum-plastic composite panel itself determines its wide range of uses: it can be used for building facades, curtain wall panels, retrofits of old buildings, interior walls and ceilings, advertising signs, display stands, engineering. Belonging to a new type of building decoration materials.

- Q: 8 # of the aluminum-plastic plate unit price,

- If the price should be 180-240 yuan / square it

- Q: Aluminum plate is not assembled aluminum plate is not paste the clock

- Aluminum plate by the coating, extrusion, bonding method made of aluminum on both sides, the middle layer of polyethylene three composite panels. The surface is generally coated, mainly as a decorative material. The general language used to paste the wall.

- Q: What is the use of aluminum-plastic plate

- Aluminum-plastic plate is also called aluminum-plastic composite panels, is a chemically treated aluminum coating for the surface material, with polyethylene plastic as the core material, in the special aluminum-plastic plate production equipment from the processing of composite materials.

Send your message to us

D.C Quality Aluminum Circles for Cookware 1XXX

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords