1/4 Inch Aluminum Strips - Aluminum 3003/ All Applications Prime Finished Aluminum Coil/ Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

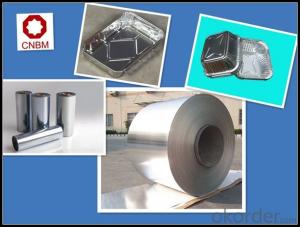

All Applications Prime Finished Aluminum Coil/ Sheet

Main Specification:

Alloy:1235/8011/8079

Temper:H14/H16/H24/H26

Thickness:0.2mm-0.3mm

| Product Name | aluminum coil |

| Alloy No. | 1050, 1060, 3003, 5052, etc |

| Thickness | 0.02-100 mm |

| Width | 40-2550 mm |

| Length | 100-6000 mm |

| Application | Gutter, constructions, decorations, air conditioning and radiators etc. |

| Package | Eye to wall or eye to air |

| MOQ | 3MT |

Applications

Super performance, 40u foil tape. Ideal for sealing joints / seams against moisture and vapor on foil jacketing insulation. Suitable for many other permanent sealing, holding, splicing or masking applications requiring the protection offered by a foil backing.Auminum foil can be divided by shape rolled aluminum foil and sheet of aluminum foil.Aluminum foil deep processing of wool roll most is supply, only a handful of handicraft industry with flake aluminum foil packing occasions.

1) What is your delivery time?

Our regular production time is over 30 days, It depends on the order quantity also.

2) What is your payment term?

We accept T/T, LC at sight, Usance LC 30, 60, 90, 120, 180 DAYS.

3) What is your price structure?

Our foil price is based on Shanghai Metal Price(SMM), not LME, but we could offer LME+ Conversion for your reference.

4) What is your Delivery term?

We do FOB, CFR, CIF, we don't do DDP

.

- Q: What types of aluminum strips are known for their durability and longevity?

- <p>Yes, there are several types of aluminum strips known for their durability and longevity. These include 3003-H14, 5052-H32, and 6061-T6 aluminum alloys. 3003-H14 is known for its excellent corrosion resistance and formability, making it ideal for applications requiring high durability. 5052-H32 offers good strength, corrosion resistance, and weldability, suitable for marine and structural applications. 6061-T6 is valued for its high strength-to-weight ratio and is commonly used in aerospace and automotive industries where long-lasting performance is crucial. Proper surface treatments and coatings can further enhance the durability and longevity of aluminum strips.</p>

- Q: The question asks for the cost of an aluminum strip.

- <p>The cost of an aluminum strip varies greatly depending on factors such as its size, thickness, quality, and market demand. Prices can range from a few dollars for small, thin strips to hundreds or even thousands for large, thick, or high-quality strips. To get an accurate price, it's best to check with suppliers or online marketplaces for current rates based on the specific dimensions and grade of aluminum you require.</p>

- Q: Is it possible to utilize aluminum strips in the construction of solar panels?

- <p>Yes, aluminum strips can be used in the construction of solar panels. They are often utilized as a component in the framing or as a conductive material in the solar cell's structure. Aluminum is lightweight, durable, and has good thermal conductivity, which makes it suitable for various applications within solar panel design. It can be used to create a protective frame, enhance heat dissipation, or serve as a part of the electrical conductors within the panel.</p>

- Q: What is the standard thickness for aluminum strip roofing materials?

- <p>The recommended thickness for aluminum strip roofing varies depending on the specific application and local building codes. Generally, aluminum strip roofing is available in thicknesses ranging from 0.018 to 0.032 inches (0.46 to 0.81 mm). For residential applications, a thickness of 0.024 to 0.028 inches (0.61 to 0.71 mm) is commonly used, while commercial buildings might require a thicker strip, around 0.032 inches (0.81 mm) for added durability and longevity. Always consult with a roofing professional or follow local building codes to determine the appropriate thickness for your specific project.</p>

- Q: This question asks about the criteria to assess whether a roof can bear the weight of an aluminum strip roof.

- <p>To determine if your roof can support an aluminum strip roof, you should consider the following: First, assess the structural integrity of your existing roof, including the strength of the rafters and the overall condition of the roof structure. Second, calculate the weight of the aluminum strip roof and compare it to the load-bearing capacity of your roof. Third, consult with a structural engineer or roofing professional who can provide a professional assessment. Lastly, ensure that your roof has adequate ventilation and drainage to prevent damage from moisture buildup, which can be exacerbated by the addition of an aluminum strip roof.</p>

- Q: Is it possible to apply paint to aluminum strips?

- <p>Yes, aluminum strips can be painted. However, proper surface preparation is crucial for good adhesion and durability of the paint. This typically involves cleaning the aluminum to remove any grease or contaminants, followed by etching or using a primer designed for aluminum to promote better paint adherence. After priming, the aluminum can be painted with a suitable paint, such as acrylic or epoxy, which are known for their compatibility with metal surfaces. It's important to follow the manufacturer's instructions for the specific paint and primer used to ensure the best results.</p>

- Q: Explain the environmental effects of utilizing recycled aluminum.

- <p>The use of recycled aluminum has a significant positive impact on the environment. It reduces the need for mining bauxite, which is the primary source of aluminum, thereby decreasing deforestation and habitat destruction. Recycling aluminum also conserves energy, as it requires only 5% of the energy needed to produce aluminum from raw materials. This energy conservation leads to reduced greenhouse gas emissions, contributing to the fight against climate change. Additionally, recycling aluminum reduces the amount of waste sent to landfills, lessening the environmental burden of waste disposal. Overall, the use of recycled aluminum promotes sustainability and helps protect natural resources.</p>

- Q: This question asks about the ease of installation for aluminum strips.

- <p>Aluminum strips are generally easy to install. They are lightweight and can be cut to size with basic tools. Installation usually involves peeling off a protective backing and adhering the strip to a clean, dry surface. For best results, it's important to ensure the surface is free of dust and grease. Some types of aluminum strips may require additional fasteners or adhesive for a secure fit, but overall, the process is straightforward and can be done by most DIYers with a little patience and attention to detail.</p>

- Q: Can the 6 square aluminum wires carry 3 pieces of air?

- Yes, please feel free to use it.

- Q: Is it possible to use aluminum strips as a covering for window or door frames?

- <p>Yes, you can use aluminum strips to cover window or door frames. Aluminum is a durable and lightweight material that can provide a sleek finish to your frames. It is resistant to corrosion and weathering, making it suitable for both indoor and outdoor applications. Aluminum strips can be easily cut and shaped to fit the contours of your frames, and they can be painted or anodized to match your desired aesthetic. However, ensure proper installation to maintain structural integrity and weatherproofing.</p>

Send your message to us

1/4 Inch Aluminum Strips - Aluminum 3003/ All Applications Prime Finished Aluminum Coil/ Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords