Aluminum 2mm Thick Aluminum Sheet Price 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

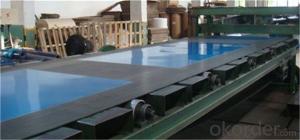

Aluminum Sheet 2mm Thick Aluminum Sheet Price 1060

Packaging & Delivery

| Packaging Details: | 25kg/carton-boxes(35*32*19CM) &Fumigation wooden-pallets (110*110*15cm) 20GP can loading 22 Ton,total 21 pallets,20 CBM. |

| Delivery Detail: | within 25 days |

Specifications

1).Excellent Surface Quality for lighting reflectors.

2).Excellent deep drawing and spinning quality.

3).Anodizing Quality

Aluminium circle/Aluminium discs/disks for cooking utensils Cookware

Aluminum disc Surface Finish: Bright & smooth surface, without flow lines, slightly oiled to avoid White rusting.Smooth,Brightly ,No Zone of Fracture ,No Scratched ,No oil Sludge

We enjoy a good reputation among our customers for our aluminum circle with high quality and competitive price, win high appreciation from our clients with the excellent workman-ship and professional ability. The quality matches with ISO 9001 quality management system.

It is equipped with 5 hot tandem rolling line, 4 cold mill production lines, 4 annealing surface machines and a complete finishing equipment.

Specification:

Alloy

Temper

Specification

Thickness

Diameter

1070,1050,3003,1100

O,H12,H14,H16

0.5-5.0mm

100-1200mm

Aluminum disc chemical Properties(WT.%)

Alloy

Si

Fe

Cu

Mn

Mg

Cr

Ni

Zn

Ca

V

Ti

Other

Min.A1

1050

0.25

0.4

0.05

0.05

0.05

-

-

0.05

-

0.05

0.03

0.03

99.5

1070

0.25

0.25

0.04

0.03

0.03

-

-

0.04

-

0.05

0.03

0.03

99.7

3003

0.6

0.7

0.05-0.2

1.0-1.5

-

-

-

0.1

-

-

-

0.15

96.95-96.75

- Q: Is it possible to utilize aluminum as a material for manufacturing solar cells?

- <p>Aluminum is not typically used to make solar cells due to its properties. Solar cells are usually made from materials like silicon, which is a semiconductor and can efficiently convert sunlight into electricity. Aluminum, being a good conductor, is used in the manufacturing process of solar cells for its electrical conductivity, but not as the active material that generates electricity. It is used in the form of aluminum paste in the back surface field of solar cells to create a conductive layer and in the frame to provide structural support. However, for the photovoltaic conversion process itself, other materials are more suitable.</p>

- Q: Is it possible to recycle old aluminum products and use them to create new aluminum products?

- <p>Yes, old aluminum products can be recycled and reused to make new ones. Recycling aluminum is a highly efficient process that conserves resources and energy. The recycling process involves melting down the old aluminum, which requires significantly less energy compared to extracting aluminum from raw materials. This makes aluminum one of the most recycled materials in the world, with a closed-loop recycling system that allows for continuous reuse without significant loss in quality.</p>

- Q: Is it possible to utilize aluminum as a material for automotive construction?

- <p>Yes, aluminum is commonly used in cars. It is valued for its lightweight properties, which can improve fuel efficiency and reduce emissions. Aluminum is used in various parts of a vehicle, including engine components, body panels, and suspension systems. Its high strength-to-weight ratio and resistance to corrosion make it an ideal material for automotive applications.</p>

- Q: Can reusing old aluminum foil be utilized for cleaning tasks in kitchen or bathroom areas?

- <p>Yes, old aluminum foil can be used for cleaning purposes in a kitchen or bathroom. It's particularly effective for scrubbing pots and pans, removing burnt-on food, and cleaning glass and tiles. The shiny side of the foil can be used to remove scuff marks from floors and the dull side can be used to scrub away stubborn stains. However, it's important to avoid using foil that has been in contact with acidic or corrosive substances, as it may have become damaged or weakened, and could potentially scratch surfaces. Always test on a small, inconspicuous area first to ensure it doesn't damage the surface you're cleaning.</p>

- Q: Is it possible to utilize aluminum in the creation of innovative battery technologies?

- <p>Yes, aluminum can be used to make new types of batteries. Aluminum-air batteries, for instance, are a type of metal-air battery that uses aluminum as the anode and air as the cathode. These batteries have a high energy density and are lightweight, making them suitable for certain applications like electric vehicles and backup power systems. Research is ongoing to improve the efficiency and lifespan of aluminum-based batteries, addressing issues such as aluminum corrosion and the development of efficient air cathodes.</p>

- Q: This question seeks to understand the impact of aluminum exposure on human health, including potential risks and consequences.

- <p>Aluminum is a common element found in the environment, and while it is generally considered safe, there are concerns about its health effects on humans. High levels of aluminum exposure have been linked to neurological disorders, particularly Alzheimer's disease, although the relationship is not definitively proven. Aluminum can also cause bone diseases and anemia, as it can interfere with the absorption of calcium and iron. Long-term exposure to high levels of aluminum may lead to cognitive dysfunction and memory loss. However, the everyday exposure to aluminum from food, water, and medications is considered safe by health authorities, and there is no need for alarm in normal circumstances.</p>

- Q: What is the reaction of aluminum with alkaline solutions and what products are formed?

- <p>Aluminum reacts with alkaline solutions in a process known as an acid-base reaction. When aluminum comes into contact with an alkaline solution, such as sodium hydroxide (NaOH), it forms sodium aluminate (NaAlO2) and hydrogen gas (H2). The reaction can be represented by the following chemical equation: 2Al + 2NaOH + 6H2O 鈫?2NaAl(OH)4 + 3H2. In this reaction, aluminum acts as an acid, donating protons to the hydroxide ions (OH-) from the alkaline solution, resulting in the formation of a salt and hydrogen gas.</p>

- Q: This question asks about the process of producing aluminum, a common metal known for its lightweight and corrosion resistance.

- <p>Aluminum is made through a process called electrolysis. The primary source of aluminum is bauxite ore, which is first refined to produce aluminum oxide. This aluminum oxide is then dissolved in a molten cryolite bath and subjected to electrolysis. A large electric current is passed through the bath, causing the aluminum oxide to break down into aluminum metal and oxygen gas. The aluminum metal sinks to the bottom of the cell and is then tapped off and further processed. This process, known as the Hall-H茅roult process, is the predominant method for producing aluminum on an industrial scale.</p>

- Q: This question asks about the reactivity of aluminum with various substances, including its chemical reactions and properties.

- <p>Aluminum is a highly reactive metal that readily reacts with oxygen to form a protective layer of aluminum oxide on its surface. It can also react with acids, such as hydrochloric or sulfuric acid, to produce hydrogen gas and aluminum salts. In the presence of a strong base, aluminum can react to form aluminates and hydrogen gas. Additionally, aluminum can reduce certain metal oxides, such as iron oxide, in a thermite reaction. However, due to its reactivity, aluminum is often used in alloys with other metals to improve its strength and corrosion resistance.</p>

- Q: What are some potential alternative uses for recycled aluminum that haven't been widely considered?

- <p>Recycled aluminum has a wide range of potential uses beyond the common ones like beverage cans and automotive parts. It can be used in the construction of buildings and infrastructure due to its strength and lightness. Additionally, it can be utilized in the aerospace industry for crafting aircraft components, given its resistance to corrosion and fatigue. In the electronics sector, recycled aluminum can be employed in the production of various components, such as circuit boards and casings. Moreover, it can be used in the creation of consumer goods like furniture, as well as in the packaging industry for food and pharmaceutical products. The versatility of recycled aluminum makes it a sustainable choice for many industries, reducing waste and environmental impact.</p>

Send your message to us

Aluminum 2mm Thick Aluminum Sheet Price 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords