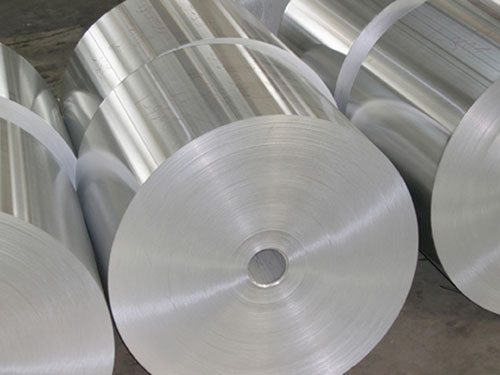

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

8011 blister aluminum foil for medicine packing:

OP/Printing/ALU/HSL

Thickness:20-25micron

Length:1000mm

8011 blister aluminum foil for medicine packing :

Applications: Blister packages for Pharmaceuticals products such as capsules, tablets, pill , pastille, small-size food , candy, etc.

Structure and application:protect layer (OP)/Outer printing layer/Aluminum foil based material (AL) inside printing layer/Bond (VC). Use in drugs blister packaging machine.

Performance and the characteristic: Excellent properties such as of anti- oxygen, moisture-proof, leak-proof,carryhome, antipollution, etc. Adopting hard anodized aluminum as cover material, it is easy to break aluminum foil to take out the drugs by pushing the cover. Adopting heat-seal coating material, which cannot be stripped,it can be bonded with all kinds of plastic-based materials.

According to printing method:

plain foil(no printing), printing foil (one-sided printing, two sided printing,single color print,double color printing, polychrome printing), color foil (one-sided golden color, two sided golden color,green bottom color,each kind of colored bottom color), forgery-proof (stealth writing, design, positive and negative printing).

Product shape: roll material.

Structures : OP (Protective layer) / Print Layer/ AL(Aluminum layer)/VC(agglutinate layer)

Specification:

Width: less than 1000mm,

Thickness: 0.02 to 0.025mm

Inner hole diameter : 76mm/152mm,

Outer diameter: 240-280mm, Length/roll:1000mm-2000mm (according to different requirement). One side is for sealing with pvc or pvc/pvdc film and other side is for printing.one side is bright and other side is dull.

Functions: High obstruction, Heat insulation, Air tightness, Printable, Breakable in slightly.

Characters: Our goods are well sealed for pinholes, coating is average with heat insulation, print is clear and beautiful with shining.

Applications: it can be applied to blister packing for capsules, pills, suppositories and mini-foods/candies, chocolate, chutty and so on.

Packing:each roll to be wrapped with sack polyethylene.outer packing:carton packing,wrap by film then pallet packing.

Why Us:

• More than 10 years experience, USD 800 million sales every year.

•Good quality control in production process,

• Excellent quality and Competitive price, OEM is available.

• Available in an extensive range of stock or custom size.

• Any port in China available.

• MOQ can meet your promotional business very well.

Trade Terms:

• Payment: T/T 30% in advance, balance against copy of B/L,Western Union.

• Production Lead Time: 5-7 after deposit paid.

• Shipping Methods: Oean carriage

• If you want to deal with EXW/CIF/CNF term instead of FOB, please specify. Otherwise, FOB price will be quoted under inquiry.

Our Service:

• Your inquiry related to our product & price will be replied within 24hours.

• Well-trained & experienced staff are to answer all your inquiries professional in English of course.

• Working time: 8:30am - 17:30pm, Monday to Saturday (UTC+8).

• OEM is highly welcomed. We have strong R&D team here to help.

• Your business relationship with us will be confidential to any third party.

• Good after-sale service offered, please get back if you got question.

Suggestion:

Please kindly check the packages after you receive the goods, if you got wrong products/ quality problem/ short q'ty, please get back to us as priority. Please note that you need to send us pictures of the defective items concerning this, and we will consider to replace or refund accordingly.

- Q: This question asks about the chemical reactions of aluminum with acids and alkalis under various conditions.

- <p>Aluminum reacts differently with acids and alkalis depending on the specific environment. In the presence of acids, such as hydrochloric or sulfuric acid, aluminum undergoes a redox reaction where it loses electrons and forms aluminum ions (Al^3+). The reaction can be represented as: 2Al + 6HCl 鈫?2AlCl鈧?+ 3H鈧? With alkalis, aluminum reacts to form aluminate ions and hydrogen gas. This reaction is represented as: 2Al + 2NaOH + 6H鈧侽 鈫?2NaAl(OH)鈧?+ 3H鈧? The rate of these reactions can be influenced by factors such as temperature, concentration, and the presence of catalysts.</p>

- Q: What other materials can be used for food packaging besides aluminum?

- <p>Alternative materials to aluminum for food packaging include biodegradable plastics such as PLA (Polylactic Acid), paper-based materials, glass, and stainless steel. Biodegradable plastics are derived from renewable resources and break down over time. Paper-based materials are sustainable and can be recycled. Glass is a non-porous material that is excellent for preserving food quality and is also recyclable. Stainless steel is durable, reusable, and does not react with food, making it a popular choice for reusable containers. Each material has its own set of advantages and disadvantages, and the choice depends on factors like food type, shelf life, and environmental impact.</p>

- Q: Explain how the incorporation of titanium into aluminum alloys influences their properties and strength.

- <p>Adding titanium to aluminum alloys significantly enhances their mechanical properties and strength. Titanium increases the alloy's strength, hardness, and resistance to corrosion. It also improves the alloy's creep resistance, which is crucial for high-temperature applications. The addition of titanium refines the grain structure, leading to better ductility and toughness. Moreover, titanium helps to reduce the likelihood of stress-corrosion cracking, making the alloy more reliable in aggressive environments. Overall, titanium-aluminum alloys are stronger, more durable, and have a wider range of applications than pure aluminum or simple aluminum alloys.</p>

- Q: This question asks about the various applications of aluminum in construction materials.

- <p>Aluminum is widely used in building materials due to its lightweight, high strength, and resistance to corrosion. It is commonly used in window frames, door frames, curtain walls, and roofing systems for its durability and low maintenance requirements. Aluminum is also used in structural components such as beams and columns, and in the manufacturing of prefabricated buildings. Its malleability allows for the creation of various shapes and designs, making it ideal for both functional and aesthetic purposes in construction. Additionally, aluminum's thermal conductivity and reflectivity properties make it suitable for energy-efficient building envelopes.</p>

- Q: This question asks about the potential dangers associated with exposure to aluminum through consumption of food and drinking water.

- <p>Aluminum exposure in food and water can pose several health risks. Chronic exposure may lead to cognitive dysfunction and Alzheimer's disease, although this link is still debated. It can also cause bone disease by leaching calcium, potentially leading to osteomalacia and osteoporosis. In the nervous system, aluminum can cause neurotoxicity, leading to symptoms like memory loss and impaired learning. Additionally, aluminum may accumulate in the brain, potentially contributing to neurodegenerative conditions. It's important to note that the extent of these risks can vary based on individual susceptibility and the level of exposure.</p>

- Q: This question asks for examples of how recycled aluminum can be utilized.

- <p>Recycled aluminum has numerous applications, including the manufacturing of beverage cans, automotive parts, construction materials, and electronic components. It is also used in the production of aluminum foil, packaging materials, and various household items. Recycled aluminum is valued for its durability, lightweight properties, and energy efficiency in production, making it an environmentally friendly choice for many industries.</p>

- Q: This question asks if there are differences in how long different types of aluminum cookware can last.

- <p>Yes, there are differences in the durability of different types of aluminum cookware. Anodized aluminum cookware is more durable and resistant to scratches and corrosion compared to non-anodized aluminum. Cast aluminum cookware is heavier and more durable than aluminum clad cookware, which is a layer of aluminum bonded to a stainless steel core. The thickness of the aluminum also affects durability, with thicker aluminum being more resistant to warping and lasting longer. Proper care and maintenance also play a significant role in the longevity of aluminum cookware.</p>

- Q: This question asks about the typical applications of aluminum pipes in various industries and settings.

- <p>Aluminum pipes are commonly used in a variety of applications due to their lightweight, corrosion resistance, and high thermal conductivity. They are extensively used in the automotive industry for parts like radiators and heat exchangers. In construction, aluminum pipes are utilized for heating, ventilation, and air conditioning (HVAC) systems. They are also used in the beverage industry for conveying and cooling liquids, as well as in the aerospace industry for fuel and hydraulic lines due to their strength-to-weight ratio. Additionally, aluminum pipes are found in industrial settings for compressed air and gas lines, and in marine applications for fuel and water systems.</p>

- Q: Is it safe and common to use aluminum in food packaging?

- <p>Yes, aluminum is commonly used in food packaging due to its lightweight, durability, and excellent barrier properties against light, oxygen, and moisture. It is often used in the form of aluminum foil and aluminum-coated films or laminates to protect food and extend its shelf life. However, there are concerns about the potential health risks of aluminum exposure, and it's important to note that regulations and guidelines exist to ensure that aluminum levels in food packaging are safe for consumers.</p>

- Q: Explain the relationship between aluminum and electrum, if any.

- <p>Aluminum and electrum are two distinct metals with no direct relationship. Aluminum is a lightweight, silvery-white metal that is the most abundant metallic element in the Earth's crust. It is known for its corrosion resistance and is widely used in various industries. Electrum, on the other hand, is a naturally occurring alloy of gold and silver, valued for its unique properties and historical significance. While both metals are used in various applications, they are chemically and physically different and do not have a direct connection.</p>

Send your message to us

Aluminum 20mic Blister Packing Aluminum Foil 8011-H18 - 0.021mm

- Loading Port:

- CN

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 7000MT m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords