Aluminum Trim Strips for Fine Stock Alloyed Series 1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

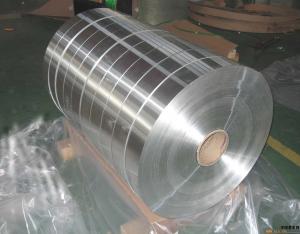

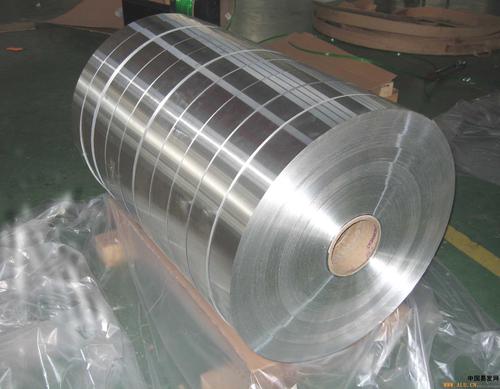

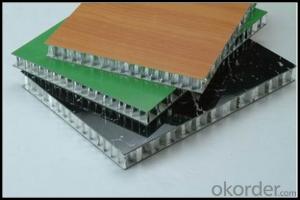

1.Structure of Aluminium Strip for Fine Stock Alloyed Serie 1 Description

DC Aluminium Strip in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of the product

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Images:

4. Product Aluminium Strip for Fine Stock Alloyed Serie 1 Specification:

ALLOY | TEMPER | THICKNESS | COATING THICKNESS | WEIGHT |

| 1050/1100 | HO-H112 | 0.2MM-3MM | 20μ-50μ | 2000KG/COIL |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Is it possible to utilize recycled aluminum for the production of roofing materials for residential use?

- <p>Yes, you can use recycled aluminum to make roofing materials for your home. Recycled aluminum is not only environmentally friendly but also cost-effective. It maintains the same properties as new aluminum, making it suitable for various applications, including roofing. Recycled aluminum roofing materials are durable, lightweight, and resistant to corrosion, which are desirable qualities for any roofing system. However, it's important to ensure that the recycled aluminum is sourced from a reputable supplier to guarantee quality and safety.</p>

- Q: What benefits does using aluminum strips provide compared to other materials?

- <p>Aluminum strips offer several advantages over other materials, including high strength-to-weight ratio, excellent corrosion resistance, and good thermal conductivity. They are lightweight, which is beneficial for reducing the weight of structures or products. Aluminum's resistance to corrosion means it requires less maintenance and has a longer lifespan. Additionally, its thermal conductivity makes it suitable for applications where heat transfer is important, such as in heat sinks or cookware. Aluminum strips are also easy to work with, allowing for easy fabrication and customization, and they are cost-effective, making them a popular choice in various industries.</p>

- Q: This question asks for the duration aluminum strips can last or their service life.

- <p>The lifespan of aluminum strips can vary significantly based on factors such as the environment in which they are used, the quality of the material, and the specific application. In general, if properly maintained and not exposed to harsh conditions, aluminum strips can last for several decades. For instance, in construction, aluminum strips used in framing can have a lifespan of 20 to 40 years. However, in more aggressive environments or with frequent wear and tear, this lifespan can be considerably shorter. It's important to note that aluminum is a recyclable material, and its lifespan can be extended through recycling processes.</p>

- Q: What types of aluminum alloys have higher tensile strength compared to others?

- <p>Yes, certain aluminum alloys exhibit superior tensile strength compared to others. For instance, 7075 aluminum alloy, known for its high strength, is often used in aerospace applications. It has a tensile strength of around 524 MPa. Another strong alloy is 2024, which is used in aircraft structures and has a tensile strength of about 425 MPa. These alloys achieve their strength through heat treatment and alloying elements like copper, magnesium, and zinc, which enhance their mechanical properties.</p>

- Q: What are the regular maintenance concerns associated with aluminum siding on buildings?

- <p>Aluminum siding is generally low-maintenance, but there are a few issues that may require attention. These include checking for dents or damage caused by impacts, ensuring proper drainage to prevent water damage, and cleaning to remove dirt and grime that can dull the finish. Additionally, it's important to inspect for signs of corrosion, especially in coastal areas with high salt content, and to address any loose or peeling paint to prevent further damage. Regular inspection and minor repairs can help maintain the longevity and appearance of aluminum siding.</p>

- Q: This question asks if there are certain types of aluminum that have a lower environmental impact compared to others.

- <p>Yes, there are types of aluminum that are considered more environmentally friendly. Recycled aluminum, for instance, has a significantly lower environmental impact compared to newly mined aluminum. The production of recycled aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum alloys with lower carbon footprints, such as those with reduced heavy metal content, can be more eco-friendly. However, it's important to consider the entire lifecycle of aluminum, including extraction, production, use, and disposal, to determine its environmental friendliness.</p>

- Q: Is it possible to utilize aluminum strips as decorative elements within a home?

- <p>Yes, you can use aluminum strips to make decorative accents for your home. Aluminum is a versatile material that is lightweight, durable, and resistant to corrosion. It can be used to create modern and sleek accents, such as trims, wall art, or even furniture accents. Due to its malleability, aluminum can be shaped into various designs and finishes, allowing for a wide range of decorative possibilities. Ensure that the aluminum strips are properly secured and finished to prevent any sharp edges and to maintain a polished look.</p>

- Q: What are the specific types of coatings applied to aluminum strips to enhance their durability?

- <p>Yes, there are specific coatings used for aluminum strips to increase their durability. These include anodizing, which forms a protective oxide layer on the surface, and various chemical conversion coatings like chromate and phosphate treatments. Additionally, organic coatings such as polyester, epoxy, and acrylic can be applied for corrosion resistance and improved surface properties. Physical vapor deposition (PVD) and hot-dip galvanizing are also used for enhanced durability and protection against environmental factors.</p>

- Q: This question asks for a list of various types of aluminum strips that are specifically used for exterior applications.

- <p>Aluminum strips used for exterior applications come in various types, each serving specific purposes. These include: 1) Architectural Aluminum Strips, used for facades and building exteriors due to their durability and weather resistance. 2) Anodized Aluminum Strips, which offer enhanced corrosion resistance and a wide range of colors for aesthetic appeal. 3) Extruded Aluminum Strips, known for their strength and customizability, suitable for structural applications. 4) Embossed Aluminum Strips, which provide a textured surface for improved grip or decorative purposes. 5) Heat Insulating Aluminum Strips, used to reduce heat transfer in exterior applications. 6) Reflective Aluminum Strips, used for safety markings or to enhance visibility in outdoor settings. Each type is chosen based on the specific requirements of the project, such as strength, appearance, and environmental conditions.</p>

- Q: What specific cleaning techniques should be employed for maintaining an aluminum strip roof?

- <p>When cleaning an aluminum strip roof, it's important to use gentle cleaning methods to avoid damaging the metal. Use a soft brush or broom to remove debris and avoid using abrasive tools that could scratch the surface. For cleaning solutions, opt for mild detergents mixed with water, and avoid harsh chemicals that could corrode the aluminum. Always rinse thoroughly to remove any residue. Never use high-pressure water or steam cleaners, as they can cause dents or warp the aluminum. Regular maintenance, such as checking for and sealing any leaks, will also help prolong the life of your aluminum strip roof.</p>

Send your message to us

Aluminum Trim Strips for Fine Stock Alloyed Series 1

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords