Aluminium Sheet Price Per Kg Cheap High Quality 1.Mm Thick Made For Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 20-25days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

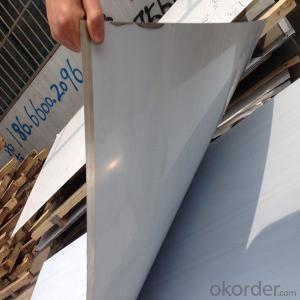

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

Photos

- Q: Can aluminum plates be welded with stainless steel or iron nuts?

- If the thickness of the sheet is not enough, the effective thread stroke can be mounted with K nuts. Rivet nuts are required if accuracy is required.If it is a thick aluminum sheet, it can be directly drilled and tapped; also, the steel screw sleeve can be added.

- Q: How does the reflective film stick to the aluminum plate?

- Put the plate clean, dry, reflective film a head from the aluminum back 2CM at the beginning attached to the aluminum plate, wrapping, pull to the front, back and side brush paper hanging tear reflective film side with the hanging brush to the aluminum paste, try to avoid bubbles.

- Q: How much is the price of the 6061 aluminum plate?

- The price is very transparent on the 6061 aluminium plate market!Manufacturers also have several: there are Henan, Zhejiang, Guangdong, Chongqing, Shanghai, but the prices are almost the same.There are 6061 aluminum sheet, plate, state difference; prices are not the same.6061 aluminum sheet price: national standard sheet 0.8-5.0, thickness 38/ kgGB thick plate 5.0-300, thickness 27/ kgNon standard alloy aluminum plate 20-21/ kg

- Q: Hey.How come iron rust and aluminium does not?DETAILED ANSWER PLEASE.I want to understand this...THANKS.

- Rust And Aluminum

- Q: Are aluminum sheets flammable?

- Aluminum sheets, I assure you, are not flammable. Their non-combustible nature is attributed to the fact that aluminum possesses a high melting point of 660 degrees Celsius (1220 degrees Fahrenheit). It neither burns nor supports combustion, rendering it a favored option in numerous sectors, particularly within the construction industry, where fire resistance is paramount.

- Q: Can the aluminum sheets be used for manufacturing automotive wheels?

- Yes, aluminum sheets can be used for manufacturing automotive wheels. Aluminum is a lightweight and durable material that is commonly used in the production of wheels due to its strength-to-weight ratio and corrosion resistance.

- Q: What are the different types of alloys used for anodized aluminum sheets?

- Anodized aluminum sheets can be made using various types of alloys, each with its own unique characteristics and uses. Some commonly used alloys include: 1. Pure aluminum, found in 1000 series alloys, is highly resistant to corrosion. It is frequently employed in anodized aluminum sheets across different industries such as architecture, automotive, and aerospace. 2. The 5000 series alloys, which contain magnesium as the primary alloying element, offer increased strength and excellent weldability. These alloys are often chosen for anodized aluminum sheets in applications that require high strength and resistance to atmospheric corrosion. 3. The 6000 series alloys are renowned for their exceptional combination of strength, extrudability, and corrosion resistance. Among this series, the 6061 alloy is widely used for anodized aluminum sheets in structural components, marine applications, and consumer electronics. 4. The 7000 series alloys are famous for their extraordinary strength and are typically used in applications that demand high-performance materials. The most commonly utilized alloy in this series for anodized aluminum sheets is 7075, which finds extensive use in the aerospace and defense industries. 5. The 2000 series alloys are mainly employed when high strength and excellent fatigue resistance are needed. These alloys are commonly used in the aerospace industry for anodized aluminum sheets. It is crucial to consider the specific requirements of the application, including desired strength, corrosion resistance, and other mechanical properties, when selecting the appropriate alloy for anodized aluminum sheets.

- Q: What is the shear strength of aluminum sheets?

- The shear strength of aluminum sheets varies based on the specific alloy and temper of the material. In general, aluminum alloys have a lower shear strength compared to steels, but higher than most other non-ferrous metals. The shear strength can range from around 30 to 60 MPa (MegaPascals) for commonly used aluminum alloys in sheet form. However, it should be noted that these values can change depending on factors like thickness, surface finish, manufacturing process, and any heat treatments applied to the aluminum sheets. Therefore, it is recommended to refer to the specific material datasheet or reach out to the manufacturer for accurate and detailed information regarding the shear strength of a particular aluminum sheet.

- Q: What is the typical fracture toughness of aluminum sheets?

- The typical fracture toughness of aluminum sheets can vary depending on the specific alloy and temper, but it is generally in the range of 20 to 35 MPa√m.

- Q: Is it possible to use aluminum sheets as a material for exterior wall covering?

- <p>Yes, aluminum sheets can be used for exterior cladding. They are known for their durability, resistance to corrosion, and low maintenance requirements. Aluminum is lightweight, which makes it easier to install compared to heavier materials. It also has good thermal properties, helping to insulate buildings. Additionally, aluminum can be coated with various finishes, allowing for a wide range of aesthetic options. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the cladding's performance over time.</p>

Send your message to us

Aluminium Sheet Price Per Kg Cheap High Quality 1.Mm Thick Made For Refrigerator

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords