Clean Aluminum Sheets for Circle Cutting in Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Sheet for Circle Cutting for Cookware Description:

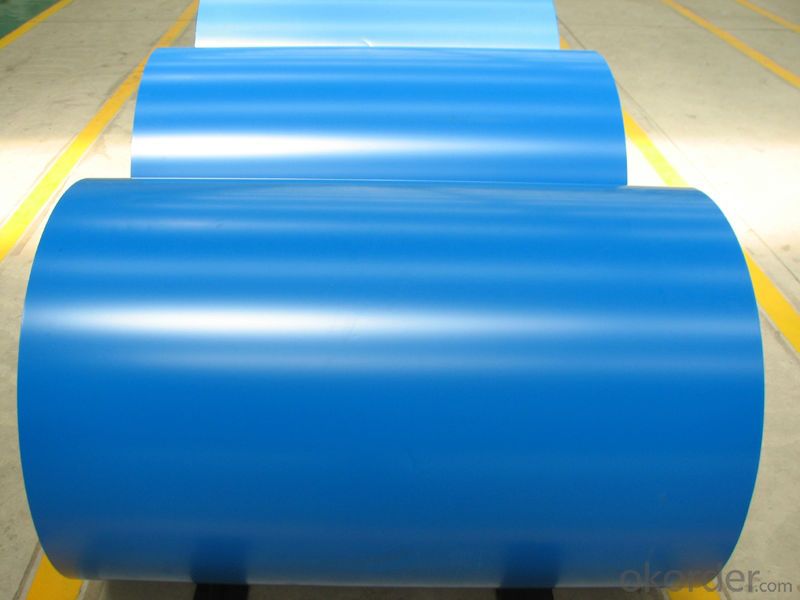

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Sheet for Circle Cutting for Cookware:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Sheet for Circle Cutting for Cookware:

Aluminium Sheet for Circle Cutting for Cookware Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: General characteristics of pure aluminium plate of pure aluminium plate

- I really want to know to call 1362889760 for your reference as follows: according to the content of different aluminum alloy elements can be divided into 8 series respectively 1***, 2***, 3***, 4***.5***.6***.7***.8*** according to the different processing technology can be divided into cold and hot rolling. They can be divided into thin plate and medium plate according to their thickness. GB/T3880-2006 standard specifies a thickness of 0.2 millimeters, called aluminum foil. More commonly used grades: pure aluminum plate, 1060 plate. Foil. Thick plate, tensile tube. Extruded tube. Type. Bar. Cold processing bar mainly for corrosion resistance in forming of high places, but not of high strength components, such as chemical equipment, marine equipment, railway tanker, conductive materials, instruments and materials, electrode etc.. 3003: plate, strip. Foil. Thick plate, tensile tube. Extruded tube. Type. Bar. Wire rod。 Cold bar, cold wire, rivet wire, forging, foil, heat sink material mainly used for processing requires good molding property, high corrosion resistance, good weldability or parts, or both have these properties need than the workpiece of 1*** alloy with high strength, such as the transport of fluids tank and tank, pressure tank, storage device, heat exchanger, chemical equipment, aircraft fuel tank, oil pipe, reflective panels, kitchen equipment, cylinder washing machine, rivet, wire. 3003 aluminum alloy sheet, plate, tube drawing. Extruded tubes, houses, partitions, roof covers, piping, etc. 3004 plates, thick plates, tensile tubes.

- Q: Are aluminum sheets suitable for decorative lighting fixtures?

- Yes, aluminum sheets are highly suitable for decorative lighting fixtures. Aluminum is a lightweight and versatile material that is easy to work with and manipulate into various shapes and designs. It offers excellent corrosion resistance, making it suitable for both indoor and outdoor lighting fixtures. Additionally, aluminum can be easily coated or painted to achieve different finishes, allowing for endless design possibilities. Its reflective properties also contribute to enhancing the overall lighting effect, making it an ideal choice for decorative lighting fixtures.

- Q: Can aluminum sheets be anodized in different finishes?

- Different finishes can be achieved when anodizing aluminum sheets. Anodizing, an electrochemical process, enhances the natural oxide layer on aluminum, increasing its thickness and durability. It is possible to customize this process to achieve clear, colored, or textured surfaces. The finish type relies on factors such as alloy composition, anodizing technique, and desired appearance. Due to their corrosion resistance, aesthetic appeal, and ability to maintain color over time, anodized aluminum sheets find extensive use in architecture, automotive, and electronics industries.

- Q: Does aluminum resist fire or is it not susceptible to catching fire?

- <p>Aluminum sheets are not fireproof but have a high resistance to fire. They do not burn or support combustion like wood or paper. Aluminum has a melting point of around 660掳C (1220掳F), and it forms a protective oxide layer when heated, which prevents further oxidation and slows down the heating process. While it can get hot and deform under extreme heat, it won't catch fire or contribute to a fire's spread. However, it's important to note that aluminum can still conduct heat, so it's not completely immune to the effects of fire.</p>

- Q: Can aluminum sheets be used as heat shields?

- Yes, aluminum sheets can be used as heat shields. Aluminum has excellent thermal conductivity, meaning it can efficiently conduct and transfer heat away from the source. Additionally, aluminum has a high melting point, allowing it to withstand high temperatures without warping or deforming. These properties make aluminum sheets an ideal choice for heat shield applications, such as protecting sensitive components or structures from heat damage in various industries including automotive, aerospace, and industrial applications. Furthermore, aluminum is lightweight and relatively easy to shape, making it a practical choice for heat shields that need to be installed in tight spaces or require complex designs. Overall, the use of aluminum sheets as heat shields offers effective thermal protection while providing durability, versatility, and cost-effectiveness.

- Q: Can aluminum sheets be used for pharmaceutical cleanrooms?

- Yes, aluminum sheets can be used for pharmaceutical cleanrooms. Aluminum is a commonly used material in cleanroom construction due to its excellent properties. It is lightweight, durable, and corrosion-resistant, making it suitable for maintaining a clean and sterile environment. Aluminum sheets can be utilized for wall panels, ceiling panels, and other surfaces within the cleanroom. These sheets can be easily cleaned and sanitized, ensuring that the pharmaceutical cleanroom remains free from contaminants. Additionally, aluminum is a non-porous material, which prevents the growth of bacteria and fungi. Therefore, aluminum sheets are a suitable choice for constructing pharmaceutical cleanrooms.

- Q: Can aluminum sheets be used for railway carriages?

- Yes, aluminum sheets can be used for railway carriages. Aluminum offers several advantages for this application. Firstly, it is lightweight, which helps reduce the overall weight of the carriage, leading to improved fuel efficiency and lower operating costs. Additionally, aluminum has a high strength-to-weight ratio, making it durable and resistant to corrosion. This is particularly beneficial for railway carriages, as they are exposed to various weather conditions and need to withstand long-term use. Furthermore, aluminum is easily formable, allowing for complex shapes and designs in the carriage structure. Lastly, aluminum is a highly recyclable material, aligning with the increasing focus on sustainability in the transportation industry. Overall, the use of aluminum sheets in railway carriages provides numerous advantages in terms of weight, strength, durability, and environmental sustainability.

- Q: How do you prevent discoloration of aluminum sheets?

- To prevent discoloration of aluminum sheets, it is important to apply a protective coating or finish to the surface. This can include using clear lacquer or anodizing the aluminum, which creates a durable oxide layer that resists corrosion and discoloration. Regular cleaning and maintenance, avoiding harsh chemicals, and protecting the aluminum from exposure to extreme temperatures can also help prevent discoloration.

- Q: This question asks for a list of various types of aluminum sheets that can be found in the market.

- <p>Aluminum sheets available on the market can be categorized based on their thickness, surface finish, and alloy composition. Some common types include: 1) Mill Finish Sheets, which have a natural aluminum finish; 2) Polished Aluminum Sheets, offering a shiny surface; 3) Anodized Aluminum Sheets, which are coated with a protective oxide layer; 4) Checkered Aluminum Sheets, with a slip-resistant pattern; 5) Painted or Coated Aluminum Sheets, with a variety of colors and finishes; 6) Embossed Aluminum Sheets, featuring decorative patterns; 7) Aluminum Foil, which is very thin; and 8) Aluminum Alloy Sheets, such as 6061, 6063, and 2024, each with specific properties for different applications. These types cater to various industries and applications, from construction to automotive and aerospace.</p>

- Q: What are the different types of alloys used in aluminum sheets?

- There are several different types of alloys used in aluminum sheets, each offering unique properties and benefits. Some of the most common alloys include: 1. 3003 alloy: This alloy is commonly used in general-purpose applications due to its excellent formability, corrosion resistance, and weldability. It is often used for cooking utensils, signage, and chemical equipment. 2. 5052 alloy: Known for its high strength and good corrosion resistance, the 5052 alloy is commonly used in marine and automotive applications. It is also used for sheet metal fabrication and structural components. 3. 6061 alloy: This alloy is highly versatile and is used in a wide range of applications, including aerospace, automotive, and structural components. It offers excellent strength, machinability, and weldability. 4. 7075 alloy: Primarily used in aerospace and high-strength applications, the 7075 alloy is known for its exceptional strength-to-weight ratio. It is often used in aircraft fittings, gears, and bike frames. 5. 2024 alloy: Another popular alloy in aerospace applications, the 2024 alloy boasts a high strength-to-weight ratio and excellent fatigue resistance. It is commonly used for aircraft structures, bolts, and rivets. 6. 5083 alloy: This alloy is specifically designed for marine applications due to its outstanding corrosion resistance and high strength. It is often used for boat hulls and structural components. These are just a few examples of the various alloys used in aluminum sheets. Each alloy has its own unique combination of properties, allowing it to excel in specific applications.

Send your message to us

Clean Aluminum Sheets for Circle Cutting in Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords