Aluminum Trailer Siding Sheets Oregon - Embossed & Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

We are able to supply 1,2,3,5,6,8 series alloy coil, foil and sheets, including 1***, 3***, 3104, 5052, 5182, 5754, 5083,5086,8011,8079

Our products include:

1). Mill-finished aluminum coil:

Alloy: AA1050, 1060, 1100, AA3003, 3005, 3015, 5052, 5754, 5083,8011 ,8079etc.

Temper: H14/16/18/22/24/32, HO etc.

Thickness: 0.08mm—100mm

Width: 100mm—2200mm (Can be slitted)

Notice: Embossment can be done if required.

2). Color-Coated Aluminum Coil:

Alloy : AA1050/1100/3003/3005/3105/5005/5052/8079 etc.

Thickness: 0.03mm—1.50mm

Width: 10mm—1600mm (Can be slitted)

Coating : PVDF, PE

Coating thickness: Usually 16-25 micron, could be33-40 micron

Color : According to customers’ requirements

Notice : Embossment can be done if required

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

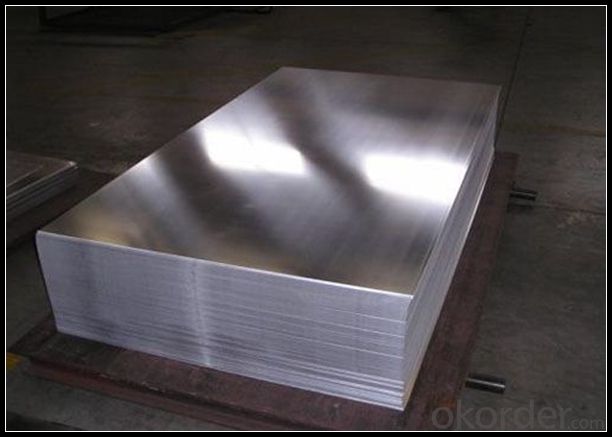

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc |

- Q: Are aluminum sheets affected by UV radiation or sunlight exposure?

- Yes, aluminum sheets are affected by UV radiation and sunlight exposure. Over time, exposure to UV radiation and sunlight can cause the aluminum sheets to oxidize, resulting in a dull and discolored appearance. Additionally, prolonged exposure to UV rays can weaken the material, making it more prone to cracking or breaking. To protect aluminum sheets from the damaging effects of UV radiation, it is recommended to apply a protective coating or use anodized aluminum, which has a more robust and durable surface.

- Q: Is it possible to incorporate windows made from recycled materials into a construction project?

- <p>Yes, you can use windows made from recycled materials in your project. There are eco-friendly windows available that are manufactured using recycled glass or other sustainable materials. These windows can offer similar performance to traditional ones while reducing the environmental impact of your construction. It's important to check the quality and certifications of the recycled windows to ensure they meet your project's requirements.</p>

- Q: What is the atomic number of aluminum?

- The atomic number of aluminum is 13.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when using aluminum sheets with concrete, several preventive measures can be taken: 1. Barrier Coating: Apply a barrier coating or paint on the aluminum sheets to separate them from the concrete. This coating acts as a protective layer, preventing direct contact between the aluminum and the concrete, thereby reducing the chances of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can be a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the risk of galvanic corrosion. 3. Surface Treatment: Apply a corrosion-resistant treatment to the aluminum sheets. Anodizing is a common surface treatment method that creates a protective oxide layer on the aluminum surface, making it more resistant to corrosion when in contact with concrete. 4. Use Dissimilar Metals: Avoid using dissimilar metals in contact with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, galvanic corrosion is more likely to occur. Therefore, it is best to use aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Proper Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can accelerate galvanic corrosion. By providing adequate drainage, you can minimize the amount of moisture that comes into contact with the aluminum, reducing the risk of corrosion. 6. Regular Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is observed, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continued protection against galvanic corrosion. By implementing these preventive measures, you can significantly reduce the risk of galvanic corrosion when using aluminum sheets with concrete, prolonging the lifespan and integrity of the aluminum and the concrete structures.

- Q: Can the aluminum sheets be used for manufacturing electrical conductors?

- Yes, aluminum sheets can be used for manufacturing electrical conductors. Aluminum is a highly conductive material and is frequently used in the electrical industry for making wires and cables.

- Q: Aluminum plate 90 degree bending, why cracking?

- Should be the aluminum sheet material and the state of the wrong, I do not know what brand of aluminum plate, with 1060 Aluminum plate, the state: soft 90 degrees bending, not cracking

- Q: I would like to make a boat, Songhua River used to know, tell the answer, good + points!

- Marine yacht with 5083, with 5456 of inland water on it, domestic Park boat 5052 will be used

- Q: This question asks for the typical dimensions of aluminum sheets utilized in the construction industry.

- <p>The standard size for aluminum sheets used in construction can vary depending on the region and specific application. However, commonly used sizes include 4x8 feet, 4x10 feet, and 5x10 feet. These sheets are typically 0.020 to 0.060 inches thick. It's important to note that custom sizes are also available to meet specific project requirements. Always check with local suppliers or industry standards for the most accurate sizing information.</p>

- Q: Are aluminum sheets resistant to UV rays?

- Yes, aluminum sheets are generally resistant to UV rays. Aluminum has a natural oxide layer that forms on its surface, which acts as a protective barrier against UV radiation. This oxide layer helps to prevent the aluminum from corroding or degrading when exposed to sunlight. However, it is important to note that prolonged exposure to intense UV radiation can still cause some degree of fading or discoloration over time. To enhance the UV resistance of aluminum sheets, they can also be coated with protective finishes or paints that provide an additional layer of defense against UV rays.

- Q: Can aluminum sheets be used for food processing equipment?

- Aluminum sheets are suitable for food processing equipment. The food industry favors aluminum for its many advantageous properties. It is lightweight, long-lasting, resistant to corrosion, and possesses excellent thermal conductivity. These attributes make aluminum sheets perfect for various applications in food processing equipment, including mixing bowls, cooking utensils, baking trays, and food storage containers. Furthermore, aluminum is non-toxic and does not interact with food, guaranteeing the safety and quality of processed products. Nevertheless, it is important to note that aluminum should not directly touch acidic or alkaline foods as it may react and impact the taste or quality of the food. In such instances, a protective barrier or lining should be employed. On the whole, aluminum sheets are extensively employed in the food industry due to their adaptability, durability, and food-safe characteristics.

Send your message to us

Aluminum Trailer Siding Sheets Oregon - Embossed & Coated Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords