1100 8006 Aluminum Coil for Aluminium Roll Coating - Decoration Inner and Outside

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Roll Coating for Decoration Innner and Outside Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Roll Coating for Decoration Innner and Outside:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

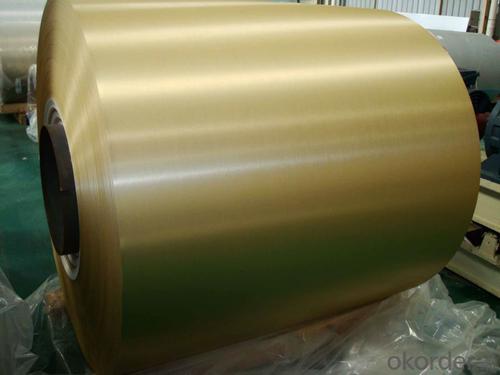

Images of the Aluminium Roll Coating for Decoration Innner and Outside:

Aluminium Roll Coating for Decoration Innner and Outside Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Guangdong where there are professional to do around the paper corner, is packing steel coil, aluminium coil that protect the edge of the both ends of the cylinder. Just the kind of picture.

- Guangdong Province, professional Foshan recommended edgeboard around Foshan Ansheng packaging. They are very professional in their circle, L shaped, and curved corners.

- Q: Tossing away an aluminum can wastes as much energy as pouring out half of that can’s volume of gasoline.what does that mean?

- Recycling aluminum saves the need from extracting new aluminum from ore, and saves the energy needed for that process.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications. Aluminum is known for its excellent thermal conductivity, which means it is highly effective in transferring heat. Aluminum coils are commonly used in various heat transfer applications such as air conditioning systems, refrigeration units, and heat exchangers. The lightweight and corrosion-resistant properties of aluminum also make it a popular choice for these applications. Additionally, aluminum coils can be easily shaped and formed, allowing for efficient heat transfer in complex systems.

- Q: How do aluminum coils compare to other metals in terms of strength?

- Compared to numerous other metals, aluminum coils possess an exceptional strength-to-weight ratio. Although not as robust as steel, aluminum is both lighter and more pliable, rendering it a favored option in diverse applications. Aluminum coils are capable of enduring substantial forces without fracturing or distorting, thereby rendering them suitable for a broad array of industries, encompassing automotive, aerospace, and construction. Furthermore, these coils exhibit commendable resistance to corrosion, thereby bolstering their longevity and durability. However, it is crucial to acknowledge that the strength of aluminum may fluctuate depending on the chosen alloy and temper. Thus, specific comparisons ought to be conducted based on the particular application and stipulations.

- Q: A magnet will not attract a aluminum bar, but if you have an electromagnetic field made by an transformer it will interact.Why is that?Why iron is attracted and wood is not?

- Aluminum is not a magnetic material and will not be affected by stationary magnets. However, if a changing magnetic field is present, an electrical voltage will be induced in the aluminum ring and an electric current will flow as a result. This current will produce a magnetic field which will interact with the externally produced magnetic field. The key here is a changing magnetic field - because the voltage induced in the aluminum ring will be proportional to the rate of change of the field. If an aluminum disk is passed between the poles of a powerful magnet, eddy currents will be induced in the aluminum producing a magnetic field that will tend to retard the motion of the aluminum relative to the magnet. The changing field in this case is due to the motion of the aluminum. Iron is attracted to a magnetic field because it is a ferro-magnetic material. Wood is not a magnetic material, and it is not an electrical conductor, so it will not behave as aluminum does in a magnetic field.

- Q: What are the different types of alloys used for aluminum coils?

- There are several different types of alloys that are commonly used for aluminum coils. The most commonly used alloy for aluminum coils is 3003. This alloy is known for its excellent corrosion resistance and moderate strength. It is often used in applications where high strength is not required, such as in roofing and siding. Another commonly used alloy for aluminum coils is 5052. This alloy has good weldability and formability, making it suitable for a wide range of applications. It is often used in the automotive industry for body panels and fuel tanks. 6061 is another popular alloy for aluminum coils. This alloy has excellent strength and is often used in structural applications. It is commonly used in the aerospace industry for aircraft parts and in the construction industry for structural components. Other alloys that are used for aluminum coils include 1100, 5005, and 8011. Each of these alloys has its own unique properties and characteristics, making them suitable for different applications. For example, 1100 is known for its high electrical conductivity and is often used in electrical applications, while 8011 is commonly used for packaging and food containers due to its excellent corrosion resistance. In summary, the different types of alloys used for aluminum coils include 3003, 5052, 6061, 1100, 5005, and 8011. These alloys offer a range of properties and characteristics that make them suitable for various applications across industries such as automotive, aerospace, construction, and packaging.

- Q: What are some common applications for aluminum coils?

- Due to their exceptional qualities and versatility, aluminum coils find widespread use in various industries. They are particularly utilized in: 1. Construction: The construction industry extensively employs aluminum coils for roofing, cladding, and insulation purposes. Their lightweight nature makes them ideal for reducing overall structure weight and providing excellent corrosion resistance. 2. Transportation: The automotive and aerospace industries widely utilize aluminum coils. In the automotive sector, they are employed in the manufacturing of heat exchangers, radiators, and condensers, as well as lightweight body panels, improving fuel efficiency. In the aerospace industry, aluminum coils are used to manufacture aircraft parts with a high strength-to-weight ratio, such as wings, fuselages, and engine components. 3. Electrical and Electronics: The electrical and electronics industry employs aluminum coils in various applications. They are commonly used in the production of transformers, motors, and generators due to their excellent conductivity and lightweight nature. Aluminum coils also find use in electrical cable manufacturing, as they offer good electrical conductivity and resistance to corrosion. 4. Packaging: The packaging industry extensively uses aluminum coils due to their excellent barrier properties. They are commonly employed for packaging food and beverages, pharmaceuticals, and other consumer products. Aluminum coils provide an impermeable barrier against moisture, oxygen, and light, ensuring the preservation and protection of packaged goods. 5. Heating, Ventilation, and Air Conditioning (HVAC): Aluminum coils are widely integrated into HVAC systems for their excellent heat transfer properties. They are commonly found in air conditioning systems, heat pumps, and refrigeration units. Aluminum coils facilitate efficient heat exchange, ensuring effective cooling and heating processes. In conclusion, aluminum coils are widely employed in the construction, transportation, electrical and electronics, packaging, and HVAC industries. Their lightweight nature, corrosion resistance, excellent conductivity, and heat transfer properties make them highly versatile and valuable in these sectors.

- Q: Can aluminum coils be used in electrical transmission systems?

- Aluminum coils have the ability to be utilized in electrical transmission systems. The utilization of aluminum is prevalent in electrical transmission systems due to its advantageous electrical conductivity, high strength-to-weight ratio, and cost-effectiveness in comparison to other materials like copper. Transformers, motors, generators, and other electrical devices benefit from the application of aluminum coils. Additionally, aluminum coils possess the advantage of being lightweight, simplifying their handling and installation in transmission systems. It is important, however, to take into account that aluminum has lower electrical conductivity than copper, necessitating larger cross-sectional areas to achieve the same electrical performance. To maintain efficiency, reliability, and safety, it is crucial to adhere to proper design and engineering practices when sizing and connecting aluminum coils in electrical transmission systems.

- Q: Relevant question 5Excuse me, what's the meaning of your "deoiling effect"? And you answer two kinds of performance, my understanding is that the oil removal effect is not good, lead to aluminum volume is not neat, what is the difference between the two? Solution, thank you

- when this phenomenon occurs in feeding occurs when you say the phenomenon, when parking tension shock or mutation, the inner drum contraction material, inner sleeve trace diameter decreases, emergency stop when the inertia torque increase, will influence on the oil film, and is the inner bag sleeve is not tight, causing the inner diameter decreases due to aluminum transfer from the inner ring to slide staggered, outer ring, the outer ring can be transferred to the volume of the material into a neat is not neat, not fully delivered appeared loose layer.

- Q: Can aluminum coils be used in automotive heat shields?

- Yes, aluminum coils can be used in automotive heat shields. Aluminum is a commonly used material in the manufacturing of heat shields due to its excellent heat resistance and lightweight properties. Aluminum coils can be formed and shaped into the desired design, allowing for easy installation and customization in automotive applications. Additionally, aluminum has high thermal conductivity, which helps to dissipate heat effectively, making it an ideal choice for heat shields in vehicles.

Send your message to us

1100 8006 Aluminum Coil for Aluminium Roll Coating - Decoration Inner and Outside

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords