6061-T4 Aluminum Coil - Aluminium Profiles with Best Price and Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Profiles with Best Price and Anodizing Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profiles with Best Price and Anodizing:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

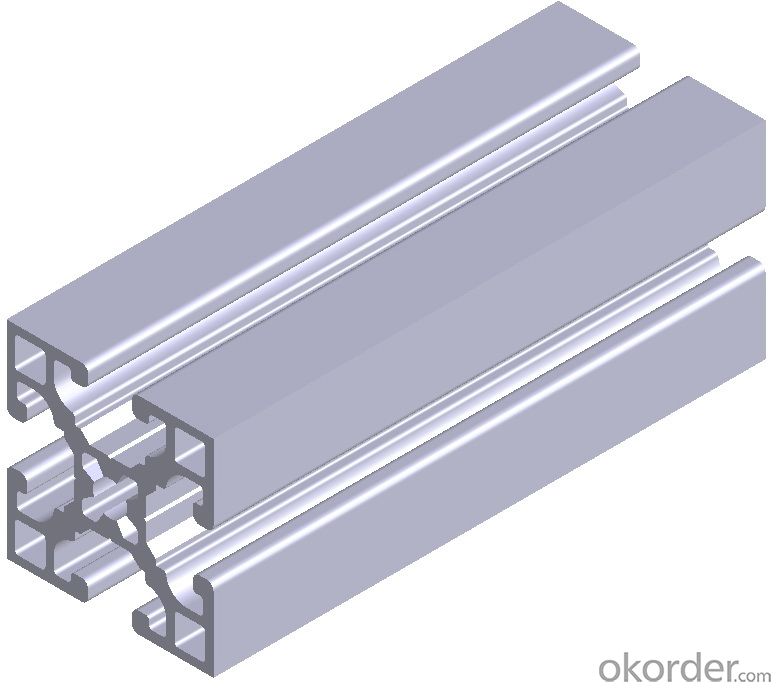

Images of the Aluminium Profiles with Best Price and Anodizing:

Aluminium Profiles with Best Price and Anodizing Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Are there any limitations to the coil weight of aluminum coils?

- Yes, there are limitations to the coil weight of aluminum coils. The weight of aluminum coils is typically limited by factors such as the capacity of the equipment used for transportation or processing, the strength and stability of the packaging materials, and the safety regulations imposed by the industry. Exceeding these limitations can lead to difficulties in handling, increased risk of damage or accidents, and may impact the overall efficiency of the manufacturing or distribution process.

- Q: This question asks about the economic impact of aluminum coils, which are a key material in various industries.

- <p>Aluminum coils significantly impact the economy by driving growth in various sectors. They are vital in construction, automotive, aerospace, and packaging industries due to their lightweight, durability, and recyclability. The aluminum coil market stimulates manufacturing, job creation, and technological advancements. Additionally, their high demand supports the growth of the aluminum industry, influencing trade and contributing to GDP. The recycling of aluminum coils also reduces energy consumption and environmental impact, further benefiting the economy by promoting sustainable practices.</p>

- Q: What are the different coil slitting methods used for aluminum coils?

- Aluminum coils can be slit using various methods, each offering distinct advantages and applications. Here are a few commonly used techniques: 1. Rotary Shear Slitting: Employing rotating circular knives, this method achieves precise and speedy cutting of aluminum coils into narrower strips. It is ideal for high-volume production of consistently sized narrow strips. 2. Loop Slitting: This method involves passing the aluminum coil through a loop, where rotating knives make the cuts. Loop slitting enables fast processing while minimizing the risk of surface damage, making it suitable for thinner gauge coils. 3. Double Knife Slitting: Using two blades, this technique makes parallel cuts along the length of the aluminum coil. It is best suited for thicker gauge coils and can produce wider strips compared to other methods. 4. Scissors Slitting: This versatile method deploys a pair of scissors-like blades to cut the aluminum coil into strips. It can handle a wide range of coil thicknesses and is commonly used in smaller scale operations or when precise width tolerances are not critical. 5. Crush Slitting: Here, the aluminum coil is pressed against a hardened roller or blade, causing it to deform and rupture along the desired cutting line. Crush slitting is ideal for delicate materials or when minimal burr formation is desired. Each slitting method has its own advantages and limitations, and the choice depends on factors such as coil thickness, desired strip width, production volume, and surface quality requirements. Selecting the appropriate method is crucial for efficient and accurate slitting of aluminum coils.

- Q: Suppose a cube of aluminum which is 1.00 cm on a side accumulates a net charge of +1.50 pC.(a) What percentage of the electrons originally in the cube was removed?(b) By what percentage has the mass of the cube decreased because of this removal?So for a you need to find total number of electrons removed (which gives it the +1.5 pC charge), and divide that by the number of total electrons in Aluminum right? 13 electrons in Aluminum..and i really don't know much else on this. I've been searching the internet for hours man

- One approach to this can use the density of aluminum to find the mass of the1 cm? block. The density of aluminum is 2.70-g/cm? so your cube has a mas of 2.70-g. The number of aluminum atoms in this block is: 2.7-g Al x (1 mol Al / 27.0-g Al) x (6.023 X 10?? atoms Al / 1 mol Al) = 6.023 x 10?? atoms Al. Each Al, as you pointed out, contains 13 electrons so we have 6.023 x 10?? atoms Al x 13 electron/atom = 7.83 x 10?? electrons. 1 x 10?? pC = 1 C and 1 C = 6.24 x 10?? electrons=== 1.5 pC x (1C / 1 x 10?? pC) x ( 6.24 x 10?? electrons / 1 C) = 9.36 x 10? electrons a.) % removed = 9.36 x 10? / 7.83 x 10?? x 100% = 1.2 x 10??? % b.) Each electron has a mass of 9.11 x 10???-g , so the total mass removed =9.11 x 10???-g/elec x 9.36 x 10? electrons = 8.53 x 10???-g. Thus the % decrease is (8.53 x 10???-g/ 2.7-g) x 100% = 3.16 x 10??? %

- Q: What is the maximum temperature aluminum coils can withstand?

- The maximum temperature that aluminum coils can withstand is influenced by several factors, which include the particular alloy of aluminum and the intended application of the coils. In general, aluminum has a melting point of approximately 660 degrees Celsius (1220 degrees Fahrenheit). Nevertheless, when it comes to aluminum coils employed in diverse industries like HVAC systems and electrical appliances, they are typically engineered to function within a temperature range of -30 to 150 degrees Celsius (-22 to 302 degrees Fahrenheit). These temperature boundaries guarantee that the aluminum coils maintain their structural integrity and avoid any notable degradation or harm. To ascertain the maximum temperature tolerance of the specific aluminum coils in question, it is crucial to refer to the manufacturer's specifications or guidelines.

- Q: Can aluminum coils be formed into different shapes?

- Yes, aluminum coils can be formed into different shapes through various processes such as bending, rolling, or stamping.

- Q: What are the different coil lengths available for aluminum coils?

- The different coil lengths available for aluminum coils can vary depending on the specific manufacturer and application. However, common coil lengths for aluminum coils range from 50 feet to 1000 feet or more.

- Q: Are there any limitations to using aluminum coils?

- Using aluminum coils comes with several limitations. Firstly, their cost is higher compared to other materials like copper, which can be a constraint for those with budget constraints. Secondly, aluminum coils have lower thermal conductivity than copper coils. This means they are less efficient at transferring heat, resulting in decreased performance in some applications. In addition, aluminum is more prone to corrosion and oxidation than other materials. This limitation is particularly relevant in highly corrosive environments, like coastal areas or industrial settings. Moreover, aluminum coils are generally unsuitable for high-pressure applications. They are more likely to experience leaks or failures under high pressure, which restricts their use in certain HVAC systems or refrigeration units. Lastly, aluminum coils are less malleable than copper coils, making them more challenging to handle during installation or repair. This can lead to increased labor costs or potential damage to the coils during handling. Overall, although aluminum coils have advantages like being lightweight and environmentally friendly, their limitations must be carefully considered based on the specific application and requirements.

- Q: Are aluminum coils prone to corrosion?

- Yes, aluminum coils are prone to corrosion. Aluminum is a reactive metal that tends to oxidize when exposed to oxygen and moisture, leading to the formation of a layer of corrosion on the surface of the coil. However, this can be mitigated by applying protective coatings or using alloys that are more resistant to corrosion.

- Q: What are the different finishes available for aluminum coils?

- There are several different finishes available for aluminum coils, including mill finish, anodized finish, painted finish, and embossed finish. Mill finish is the standard finish and has a smooth, shiny appearance. Anodized finish involves an electrolytic process that adds a protective layer to the aluminum, providing increased durability and resistance to corrosion. Painted finish involves applying a coating of paint to the aluminum, offering a wide range of color options and enhanced aesthetics. Lastly, embossed finish involves creating patterns or textures on the aluminum surface, adding visual interest and improving grip.

Send your message to us

6061-T4 Aluminum Coil - Aluminium Profiles with Best Price and Anodizing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords