1060 Aluminum Coils Wholesale - Aluminium Profile 180T Best Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

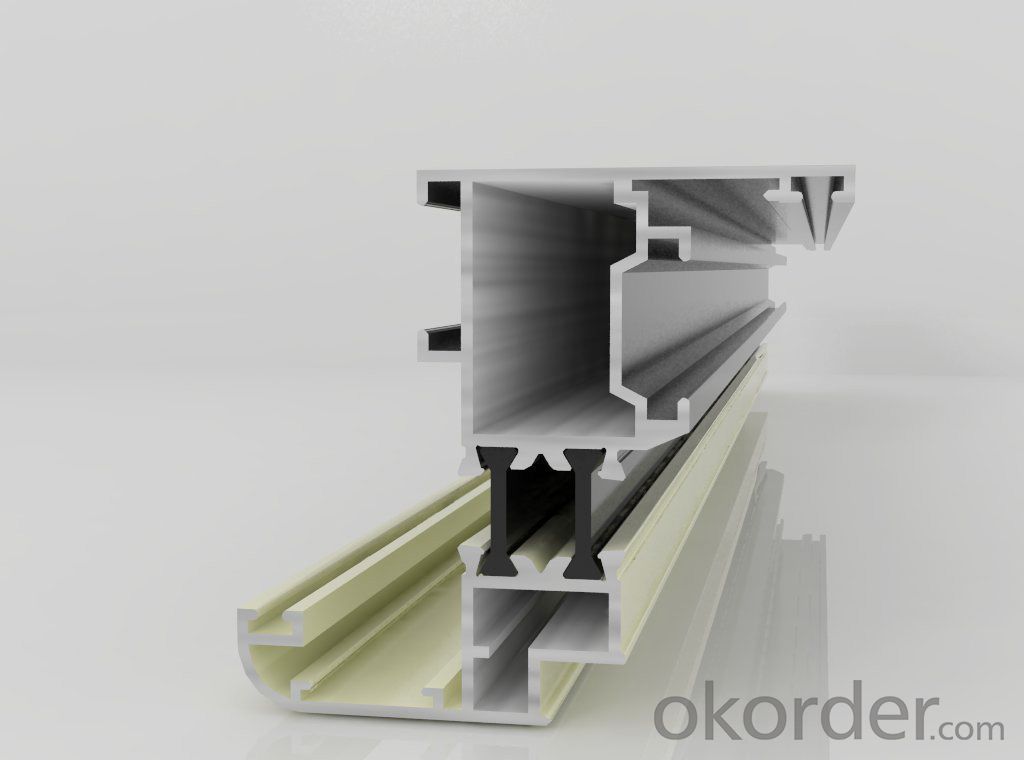

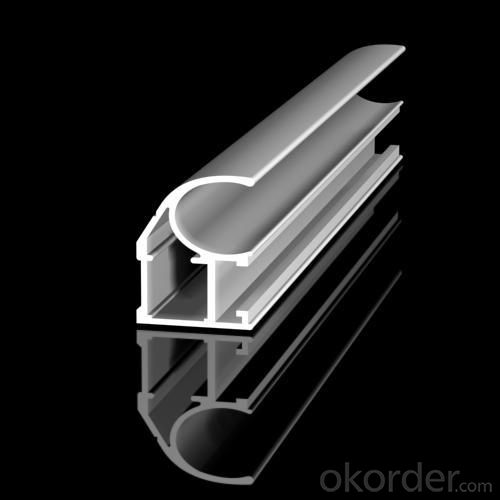

Structure of Aluminium Profile 180T Best Price and Good Quality Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Profile 180T Best Price and Good Quality:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Profile 180T Best Price and Good Quality:

Aluminium Profile 180T Best Price and Good Quality Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: Well, we've got the existing old school 7 layers of peeling yucky painted siding and we're trying to weigh our options. So here's my questions:1) Is it cost effective to replace Aluminum with Vinyl?2) Is Vinyl truly as costly as we keep hearing? **Home is small 1,100 sq.ft with a 2.5 car Garage**3) Is painting this existing siding a wise choice since the current paint job on it looks terrible? We just need to make it more a home, right now it's gorgeously all new and redone inside and on the outside it still resembles the day we bought it in forclosure. Aside from my green grass I busted my butt on last summer.Please advise.

- Vinyl siding, the kind that is single thickness with no backer, will bend, buckle, and distort in about 5 years. The vinyl siding with foam backer is somewhat better but not much. It will look badly in years to come. . Just drive around and look at some of those homes built just a couple years ago with that stuff on them. Notice how twisted and buckled and bent and crooked that stuff has become. Plain terrible I think. Paying that much for a house, it should last a lifetime. There are COATING companies around that will come and clean your existing aluminum siding, They will remove dents, apply a 2 part epoxy primer, and then a two part Vinyl coating that will last for 30 years under a warranty. These coatings can also be applied to wood siding, they give it a renewed look, and no painting ever again. You cannot do this yourself. It is done with airless type sprayers and it lasts literally forever. I had this done to my aluminum underhangs and gutter and wood window wells on my brick house. That stuff is so tough and smooth that even dirt or dust doesnt stick to it. Look under Vinyl Coatings in the Yellow Pages. If there is a home show in your area, go to one of those and you can see these new coatings. They are really superior to any painting you can do yourself, Yes, they cost a bunch more but they are well worth it in the long run. That Aluminum on there is 100 Times better than any vinyl will ever be. It will last indefenitely. Dont be fooled by some vinyl salesman's pitch of insulating qualities of vinyl with that thin 1/4 inch of foam on the back. That is nonsense, that thin of a foam in a side wall means nothing on insulation value for your house. Stick with your Aluminum and your wood siding and window trims, get it coated and you will be very happy with that.

- Q: Can aluminum coils be used for heat transfer applications?

- Yes, aluminum coils can be used for heat transfer applications due to their excellent thermal conductivity properties.

- Q: How are aluminum coils protected against scratching and abrasion?

- Various methods and coatings are utilized to protect aluminum coils from scratching and abrasion. One commonly employed technique involves applying a protective film or coating to the coils' surface. This film acts as a barrier, shielding the aluminum from external forces that may lead to scratching or abrasion. In addition, aluminum coils can undergo an electrochemical process called anodizing, which generates a protective layer on the aluminum's surface. This layer not only increases the coil's resistance to scratching and abrasion but also enhances its durability and corrosion resistance. Protective lacquer or paint can also be applied to aluminum coils to safeguard them. This coating not only enhances the coils' visual appearance but also acts as a barrier against potential scratches or abrasion. These protective coatings can be customized to meet specific requirements, such as UV resistance or chemical resistance. Furthermore, aluminum coils can be manufactured with a textured or patterned surface, which creates a more robust surface that is less susceptible to scratching or abrasion. The texture helps distribute external forces more evenly, reducing the chances of damage. Overall, a combination of protective films, anodizing, protective coatings, and textured surfaces is employed to ensure the longevity and performance of aluminum coils in various applications while safeguarding them against scratching and abrasion.

- Q: Can aluminum coils be used for HVAC condenser coils?

- Indeed, HVAC condenser coils can utilize aluminum coils. In recent times, aluminum coils have gained significant popularity owing to their myriad benefits over conventional copper coils. With their lighter weight and enhanced durability, aluminum coils exhibit superior resistance to corrosion. Additionally, they boast exceptional heat transfer properties that enable efficient refrigerant cooling. Furthermore, aluminum coils prove to be more cost-effective and environmentally sustainable in comparison to copper coils. All in all, opting for aluminum coils for HVAC condenser coils is a viable and advantageous choice.

- Q: What are the advantages of using aluminum coils in HVAC systems?

- There are several advantages to using aluminum coils in HVAC systems. Firstly, aluminum coils offer excellent heat transfer properties, allowing for efficient cooling and heating of air. They also have a high resistance to corrosion, ensuring durability and longevity of the HVAC system. Additionally, aluminum coils are lightweight, making installation and maintenance easier. Finally, aluminum is a sustainable and recyclable material, making it an environmentally friendly choice for HVAC systems.

- Q: Is it possible to construct a lampshade using an aluminum coil?

- <p>Yes, you can use an aluminum coil to make a lampshade. Aluminum is a lightweight, durable, and heat-resistant material, making it suitable for lampshade construction. You can bend and shape the coil into a desired form and attach it to the lamp base. Ensure proper electrical insulation and avoid direct contact between the coil and the light bulb to prevent overheating. It's advisable to use a professional or follow detailed instructions to ensure safety and a quality result.</p>

- Q: How do aluminum coils contribute to sustainable manufacturing?

- Aluminum coils contribute to sustainable manufacturing by offering numerous environmental benefits. Firstly, aluminum is a highly recyclable material, meaning that the coils can be reused repeatedly without any degradation in quality. This reduces the need for virgin aluminum extraction, saving energy and resources. Additionally, the lightweight nature of aluminum coils reduces transportation costs and fuel consumption during shipping. Furthermore, aluminum is corrosion-resistant, leading to longer product lifespans and reducing the need for frequent replacements. Overall, the use of aluminum coils promotes sustainability through efficient resource utilization, reduced emissions, and increased product longevity.

- Q: I have been reading up on thermite and the required ingredients. I have extremely fine aluminum powder from a small etch-a-sketch sitting on plastic wrap in my room. On the comments page of the site i got the thermite ingredients from, multiple people said that thermite could explose if you use too fine of a powder. I have also read that powdered aluminum can become very explosive when it is exposed to air or if it becomes damp. Ive gotten particulary worried because the humidity right now is 93%. So, is powdered aluminum too dangerous to have in house and is too fine powdered aluminum explosive when in thermite?

- Powdered aluminium isn't explosive, and any humidity or dampness in the air won't affect it. Really finely powedered aluminium is nothing but an extremely powerful reducing agent. In other words, it won't explode, but it will burn very fast and very hot. When combined with magnesium powder, it contributes to the nature of thermite in a reduction-oxidation reaction. On it's own however, as long as you keep it away from any open flames, it's perfectly safe. I should say; be very, very careful with making thermite. It's not explosive on it's own, but if you make it wrong, it can fizzle and pop and send molten metal flying your way.

- Q: Does anyone know if aluminum skateboards are good?

- I haven't seen one since the old QuickSilver-Silver Surfer(circa 1979). They look great, but they become useless when scratched. Which means....you can't really use them for anything. They're not as flexible as wood....and.......Wait until you get hit in the shin with an aluminum skateboard. Aircraft metal my(explicative deleted). My guess is they're inexpensive because they're trying to get the word out. The company owners probably no very little about skateboarding.

- Q: Is it possible to utilize aluminum coils in the packaging of food products?

- <p>Yes, aluminum coils can be used for food packaging. They are commonly used in the production of aluminum foil, which is a popular material for food packaging due to its properties such as light weight, barrier to light and oxygen, and recyclability. Aluminum foil is used to wrap food, line baking sheets, and create containers, providing a protective barrier that helps to preserve freshness and extend shelf life. However, it's important to ensure that the aluminum used meets food-grade standards to avoid any health risks.</p>

Send your message to us

1060 Aluminum Coils Wholesale - Aluminium Profile 180T Best Price and Good Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords