Aluminum Profiles and Accessories for Solar Panel Frame Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Aluminium Profiles for making Solar Panel Frame Description

Aluminium Profiles for making Solar Panel Frame is one semi-finished aluminium material. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Specification of Aluminium Profiles for making Solar Panel Frame

Aluminium Profiles for making Solar Panel Frame | |

Main Specification | |

Alloy | AA1xxx (AA1050, AA1060, AA1070, AA1100 etc.) |

AA3xxx (AA3003, AA3004, AA3005, AA3105 etc.) | |

AA5xxx, AA6XXX (AA5052,AA5083, AA5754, AA6061, AA6062 etc.) | |

AA8xxx(AA8011, AA8006 etc.) | |

Temper | H14,H16, H18, H22, H24, H26, H32,O/F, T4, T6, T651 |

Thickmess | 0.01mm-100mm |

Width | 30mm-1700mm |

Standard | GB/T 3880-2006/ASTM |

Special specification is available on customer's requirement | |

3. Application of Aluminium Profiles for making Solar Panel Frame

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

4. Feature of Aluminium Profiles for making Solar Panel Frame

Surfact Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mechenical Property:

Chemical Composite and Mechanical Property

5. Certificate of Aluminium Profiles for making Solar Panel Frame

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

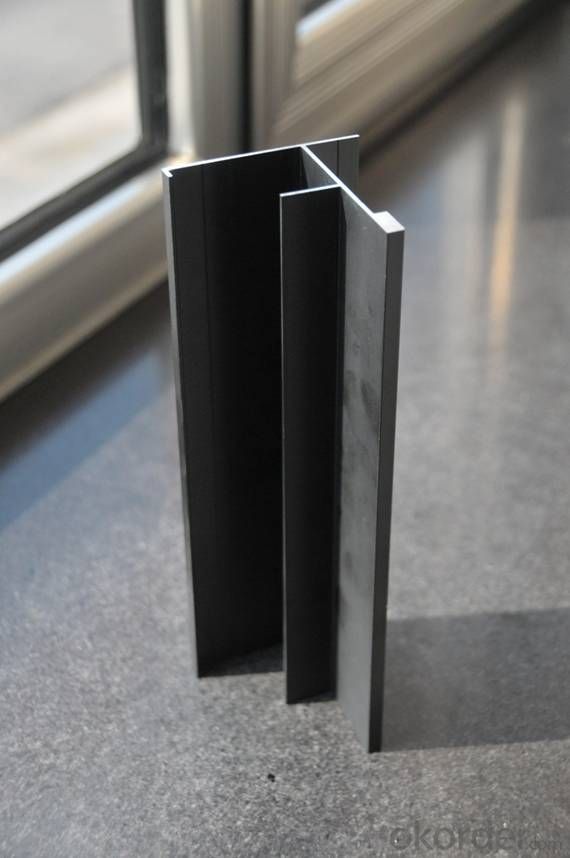

6. Image of Aluminium Profiles for making Solar Panel Frame

7. Package and shipping of Aluminium Profiles for making Solar Panel Frame

First, plastic cloth with drying agent inside; Second, Pearl Wool ; Third, wooden cases with dry agent , fumigation wooden pallets, aluminum surface could cover blue PVC film

8. FAQ

1) What is the delivery time?

Depends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the surface hardness properties of aluminum profiles?

- The surface hardness of aluminum profiles can differ depending on the specific alloy and treatment processes used. In comparison to metals like steel, aluminum alloys generally have lower hardness. However, by employing various treatments, aluminum profiles can achieve improved surface hardness. One commonly used treatment method is anodizing, which involves the creation of an oxide layer on the aluminum surface. Not only does this process enhance the corrosion resistance of the profiles, but it also increases their surface hardness. Depending on the thickness of the oxide layer, anodized aluminum profiles can have a hardness ranging from 150 to 300 HV (Vickers hardness). Another treatment process is hard coating, where a ceramic material like aluminum oxide is applied to the surface of the profiles. This coating drastically enhances the hardness of the aluminum, providing a higher level of wear resistance. The hardness of hard-coated aluminum profiles can range from 400 to 600 HV or even higher. It is important to note that the specific hardness properties can vary based on the alloy composition, surface treatment method, and intended application of the aluminum profiles. Hence, it is crucial to consult manufacturers or suppliers to determine the appropriate hardness properties that best suit your specific needs.

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: A curtain wall predecessors?For example, under the transverse frame section, with 6m specifications, why should the material processing and minus 50mm? Insert plate, plate to cut 100mm head? What is the law?

- The column beam rod in the visual profile factory when surface treatment to hang up or put the spraying profile in oxidation tank, in sections at each end of the play of a hole, so that the hook, in the cutting process, in order to avoid the holes will be seen after the installation and so on when will the cutting part of the section cut ends, this is to cause less 50mm. As you said the core insert to reduce 100mm plate plate, this is because the length of processing of these parts is relatively small, some ten centimeters in length, the process if you use a single head saw or double saw large mechanical cutting, base metal processing machinery in a relatively short time finally can not be cut, that is to say the last 100mm~150mm machine cannot continue cutting, it is useless.

- Q: Can aluminum profiles be used for industrial workbenches?

- Yes, aluminum profiles can be used for industrial workbenches. Aluminum is a lightweight and durable material that is commonly used in industrial applications. It offers excellent strength-to-weight ratio, corrosion resistance, and can be easily customized to suit specific needs. Additionally, aluminum profiles can be easily assembled and disassembled, allowing for flexibility and easy modifications to the workbench layout.

- Q: What are the different surface protection coatings for aluminum profiles?

- Some of the different surface protection coatings for aluminum profiles include anodizing, powder coating, painting, and electroplating. Anodizing forms a protective oxide layer on the surface, while powder coating and painting provide a durable and decorative finish. Electroplating involves depositing a thin layer of metal onto the surface to enhance its corrosion resistance.

- Q: The user is inquiring about the efficiency of aluminum profile recycling in their region and seeks details on how it can be done.

- <p>Yes, aluminum profiles can be recycled efficiently in most regions due to their high value and the relatively low energy required for recycling. The process typically involves collection, sorting, melting, and recasting into new aluminum products. To recycle aluminum profiles in your region, you can check for local recycling centers or scrapyards that accept aluminum. Some municipalities also have curbside recycling programs that include aluminum. Ensure that the profiles are clean and free of non-aluminum components before recycling to maximize their value and efficiency in the recycling process.</p>

- Q: How do aluminum profiles perform in vibration isolation applications?

- Due to their unique properties and characteristics, aluminum profiles prove to be highly effective in applications involving vibration isolation. The utilization of aluminum profiles in such scenarios aids in the reduction and mitigation of vibrations, thereby establishing a stable and isolated setting. The high strength-to-weight ratio of aluminum profiles stands as one of the primary factors contributing to their efficacy in vibration isolation. Aluminum, being a lightweight material, enables the construction of structures capable of efficiently absorbing and dissipating vibrations. This lightweight nature ensures that the profiles do not add excessive weight to the system, as doing so could amplify vibrations instead of dampening them. Furthermore, aluminum profiles exhibit exceptional damping capabilities. Damping refers to a material's ability to absorb and dissipate energy from vibrations. Aluminum inherently possesses damping properties, which play a significant role in diminishing vibration levels. As a result, the profiles effectively isolate vibrations and prevent their transmission to other components or structures. In addition, aluminum profiles can be easily customized and designed to meet specific requirements regarding vibration isolation. Engineers can tailor the profiles' geometries and configurations to effectively attenuate vibrations. This design flexibility permits the optimization of profiles for diverse applications and environments, ensuring maximum effectiveness in vibration isolation. Moreover, aluminum profiles offer commendable corrosion resistance, a crucial factor in vibration isolation applications exposed to harsh operating conditions. This resistance to corrosion guarantees the durability and reliability of the profiles, maintaining their performance over extended periods. In conclusion, due to their lightweight nature, excellent damping capabilities, customization options, and corrosion resistance, aluminum profiles prove to be highly suitable for vibration isolation applications. Through their efficient absorption and dissipation of vibrations, aluminum profiles enable the creation of stable and isolated environments, effectively minimizing the impact of vibrations on surrounding components or structures.

- Q: How to distinguish the true and false of aluminum profile

- Al Feng brand aluminum precision identification method is to do chemical detection. But in the absence of our conditions, we can only use "observation" to distinguish. What is "observation method", that is, we make a different perspective on the surface of aluminum. Aluminum door and window section is made of aluminum rod by die extrusion and the like, fake phoenix aluminum using bauxite as raw material, so the material contains a lot of impurities, extrusion is easy to mold galling, the surface profile produced is not smooth, there are many marks, and profiles of scrap produced. Can not be reached in a variety of physical effects on strength and hardness.The surface treatment of fake profiles for powder coating (common color: green, white, grey), said simply in this way, the profile above is squeezed out of the powder coverage, this method has great advantage on fake garbage can be squeezed out of aluminum profiles, profiles on the marks effectively cover. But because of fraud for more cost savings, they use inferior adhesion powder, short life, easy to fall off, and covered in the profile of the powder also small and thin, and extruded profile marks are too deep, even if there is a cover up the layer of powder, as long as viewed from different angles and shapes position still, it is easy to see these ugly marks.

- Q: Are aluminum profiles suitable for decorative applications?

- Yes, aluminum profiles are suitable for decorative applications. They are versatile, lightweight, durable, and can be easily customized to suit various design styles. Additionally, aluminum profiles offer a sleek and modern appearance, making them popular choices for decorative purposes in both residential and commercial settings.

Send your message to us

Aluminum Profiles and Accessories for Solar Panel Frame Making

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords