Aluminum Sheets for Sale - Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile Building Expansion Joints Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Building Expansion Joints:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

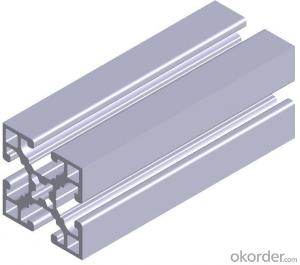

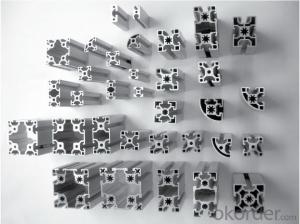

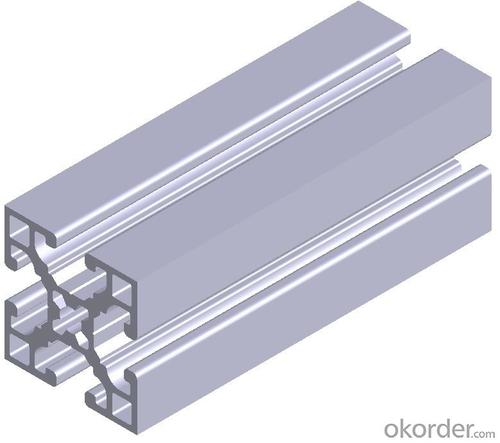

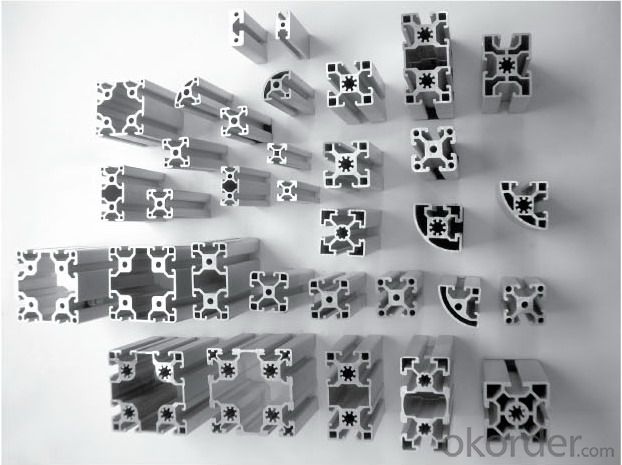

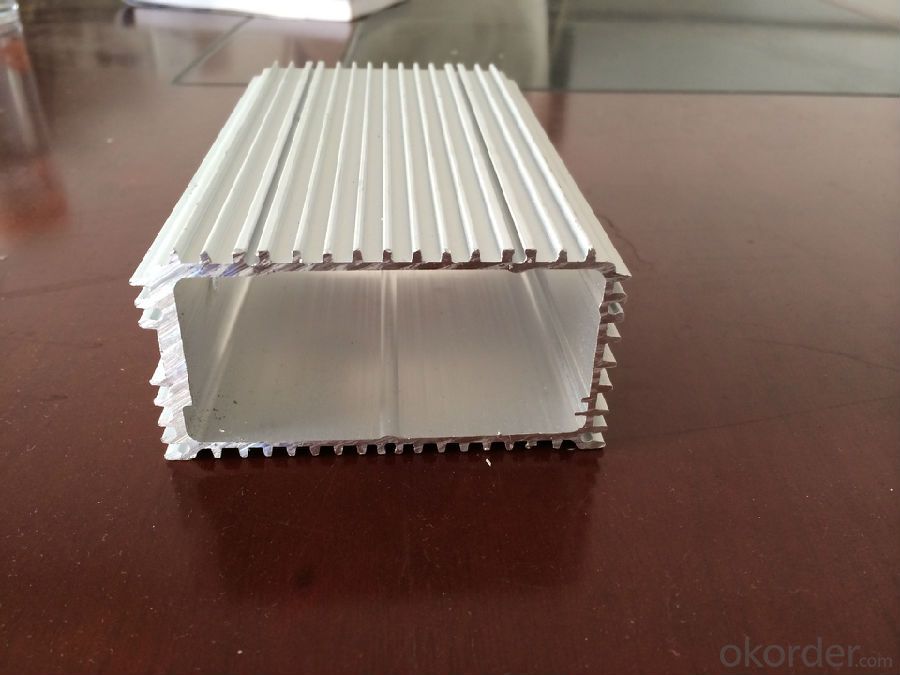

3.Aluminium Profile Building Expansion Joints Images:

4.Aluminium Profile Building Expansion JointsSpecification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do aluminum sheets perform in extreme temperatures?

- Aluminum sheets are known for their excellent performance in extreme temperatures. Aluminum has a high melting point, around 660 degrees Celsius, which makes it capable of withstanding high temperatures without deforming or melting. In extreme heat, aluminum sheets have a low thermal expansion rate, meaning they will not expand or contract significantly, ensuring dimensional stability. This makes them ideal for applications in industries such as aerospace, automotive, and construction, where extreme temperatures are common. Similarly, in extremely cold temperatures, aluminum sheets retain their strength and durability, unlike some other metals that become brittle and prone to cracking. Additionally, aluminum has excellent thermal conductivity, allowing it to distribute heat evenly, which is beneficial in applications where heat dissipation is crucial. Overall, aluminum sheets perform exceptionally well in extreme temperatures, making them a reliable choice for various industries.

- Q: how many aluminum ions are present?how many chloride ions are present?what is the mass in grams of one molecule of aluminum chloride?help! i have no clue how to do this i need to know how for my quiz!!!

- You have to remember Avogadro's number: 6.02 x 10^23 Read about it in your text book. It is the number of molecules of any atom that make up 1 mole. 1 mole of a molecule is equal to it's atomic weight in grams. So, the atomic weight of aluminum is 26.9. So, 26.9 grams of aluminum contains exactly 6.02 x 10^23 molecules of aluminum (or 1 mole). What's the molecular weight of aluminum chloride? Well, 26.9 + 3(35.5) = 133.4 the 35.5 is the molecular weight of chloride and there are 3 of them. So, 133.4 grams of aluminum chloride would be 6.02 x 10^23 molecules. We only have 37.2 g. 37.2 g/ 133.4 g per mole = 0.279 moles. 0.279 moles x (6.02 x 10^23 molecules/mole) = 1.68 x 10^23 molecules of aluminum chloride. So, since there is one aluminum per molecule, you have your answer. Just multiply by three to find out how many molecules of chloride are present. Finally, if 133.4g = 6.02 x 10^23 molecules, then 1 molecule = 133.4 / 6.02x10^23 = 22.16 x 10^-23 or 2.216 x 10^-22 Make sure that the periodic table you use for class has the same values (some tables are more simplified then others). Also, make sure that you use the correct number of scientific digits when calculating your answer.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays.

- Q: just bought a hobart handler 140 (already love it), and was just wondering on what gas to use for aluminum. my welder will be set up for mild steel (75% argon 25% CO2). it would be nice to be able to use this mix with aluminum as well, as it would be easy to just switch spools of wire, but the manual says to use a 100% argon mix when welding with aluminum. will the 25% CO2 make a difference welding aluminum?

- You MUST use 100% Ar for MIG welding aluminum. Molten Al is highly reactive. Al powder is the active ingredient in thermite, for example. It will react with CO2, stripping away the oxygen and creating a nasty mess. Also, you really need a MIG welder with twice as much current output. along the lines of 200-300 amps. 130 amps will not perform well even with a spool gun, and running the weak, prone-to-jamming .030 Al wire. You could try to do it that way, but I would not advise. (There is no way in hell you'd be able to cram wimpy .030 Al wire through a 6 foot traditional welding lead. It'll kink and jam after 5 seconds.) MIG welding aluminum REQUIRES using the high-current, high feed speed, spray transfer mode. Here are some typical parameters: 030 wire, 500 IPM, 22 volts. 120-130 amps. 035 wire, 500 IPM, 23 volts, 150 amps. 045 wire, 400 IPM, 24 volts, 200 amps. EDIT, the guy above me has the right idea. They use electricity to force the reaction between aluminum oxide (dissolved in cryolite) and carbon, producing molten Al and CO2 gas. Normally the reaction would tend to go the other way. Aluminum has a higher affinity for oxygen.

- Q: Can aluminum sheets be used for reflective surfaces?

- Indeed, reflective surfaces can be crafted using aluminum sheets. Renowned for its exceptional reflectivity, aluminum proves to be an ideal material for producing such surfaces. With its sleek and impeccably polished texture, aluminum sheets efficiently bounce back light, heat, and various types of radiation. This remarkable attribute renders them suitable for an extensive array of purposes, encompassing solar panels, mirrors, lamp reflectors, and reflective insulation. Utilizing aluminum sheets as reflective surfaces offers numerous advantages, including their enduring nature, lightweight composition, and resistance to corrosion.

- Q: What kind of aluminum sheet can be bent with five millimeters?

- The aluminum plate can be bent five milimeter too much, if only bending words and aluminum quality has little relationship.First of all, the state is the most important, the state is divided into hard, semi hard, soft (usually soft called O state)The bending effect of the whole hard is not too far (the aluminum plate is H18, H19, H38 and so on are all hard)Semi hard aluminum sheets can basically be bent (H24, that is, semi hard)O bending is certainly not a problem, but because of too soft, basically with this state to bend lessSecond, you have to choose pure aluminum or alloy aluminum?Pure aluminum hardness is not very good, with 1100, 1050, 1060 and so on can be recommended 1100 H26Alloy aluminum hardness is better, can use 3003, 3005, 5052 and other semi hard state can be.Specific recommendations were then determined by 6061, 2024, 7075 if the hardness is too high, especially for the T6 state is more, should not bend, unless you're heating and folding the difference between aluminum and aluminum is poor oxidation resistance, tolerance, surface effect, crystal accuracy and the uniform stability of a difference, not only the bending effect difference.If the aluminum surface paint it quality do not too good, good is a waste, it is recommended to use 3003-H26, 3005H24 or 5052H34, the price of twenty pieces of it, made up to more than forty yuan per kilogram

- Q: heating can affect aluminium

- This is science so, if you want specific answers, you must ask specific questions. What type of aluminum are you interested in? What characteristics are important to you? What kind of factors are you talking about? You are right that heating can affect Al. In fact, heating affects, basically, everything, every material we know of and every physical and chemical process that we do and every process that happens in nature. Temperature is important in all of these. There are more than a hundred different commercial aluminum alloys and most of them are available in a variety of different tempers (heat treated conditions). The heat treatment of commercial Al alloys is a very important thing. If you want more specific information, consult your friendly neighborhood metallurgist.

- Q: I wish to purchase an 8' step ladder as well as a medium length extension ladder. What are the pros and cons of aluminum vs. fiberglass?

- Fiberglass Vs Aluminum Ladder

- Q: What are the different types of surface coatings for aluminum sheets?

- There are several types of surface coatings available for aluminum sheets, including anodizing, powder coating, painting, and laminating.

- Q: How do you prevent discoloration of aluminum sheets?

- In order to avoid discoloration of aluminum sheets, there are a few steps that can be taken. First and foremost, it is crucial to regularly clean the aluminum sheets to eliminate any dirt or debris that may potentially cause discoloration. Utilize a mild detergent or a specialized aluminum cleaner, along with a soft cloth or sponge, to gently scrub the surface. It is advisable to refrain from using abrasive cleaners or scrubbing pads, as they have the potential to scratch the surface and increase the likelihood of discoloration. Secondly, it is essential to thoroughly rinse the sheets after cleaning to eradicate any residue from the cleaning products. Residual chemicals can react with the aluminum and result in discoloration over time. Another preventive measure entails applying a protective coating or sealant on the aluminum sheets. This can establish a barrier between the metal and the surrounding environment, thus preventing oxidation and discoloration. There are diverse types of protective coatings available, such as clear lacquers or anodizing treatments, which can enhance the durability and appearance of the aluminum sheets. Moreover, proper storage of the aluminum sheets is paramount to minimizing exposure to moisture, humidity, and extreme temperature fluctuations. Moisture can expedite the oxidation process and lead to discoloration. It is recommended to store the sheets in a dry and well-ventilated area, away from direct sunlight or sources of heat. Consistent maintenance is vital to prevent discoloration. Periodically inspect the aluminum sheets for any indications of discoloration or damage, and promptly address any issues that arise. By adhering to these preventive measures, the aesthetic appeal and longevity of aluminum sheets can be maintained.

Send your message to us

Aluminum Sheets for Sale - Aluminium Profile Building Expansion Joints

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords