Color Aluminum Coil Prepainted-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Aluminium Coil Prepainted Description

Prepainted aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The prepainted aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of Aluminium Coil Prepainted :

1) Perfect weather ability, high strength, no special maintenance

2) Convenient construction, short working time

3) Excellent machining heat insulation, sound insulation property and perfect fireproof performance

4) High plasticity, good impact resistance, quakeproof performance and reducing buildings load

5) Goods smoothness, lightweight and rigid, beautiful and cheap

6) Various colors available

7) Simple machining equipments, processing in spot.

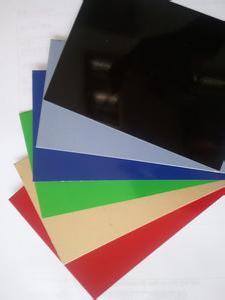

Image of Aluminium Coated Coil:

Aluminium Coated Coil Specification:

Product Name | Aluminum Coil |

Alloy | A1100,A3003,A1050,A8011,A3105,A5005 etc |

Thickness | 0.022mm to 3.0 mm |

Width | Standard width:1240mm; 1200mm |

All width: 30mm - 1600mm | |

Diameter | out dia:1200mm |

Interior dia: 405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE,PVDF,ACRYLIC |

Surface | Embossed, mill finish, coated; aluminum gutter coil |

Color | AS to all RAL color |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ of AA5052 Aluminium Coated Coil:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How to measure the thickness of aluminum coil at real time? In what areas can the sensor be used?

- I suggest that you use the laser displacement sensor for real-time measurement of the thickness of aluminum coil. ZLDS100 can exactly measure the change value of aluminum coil thickness through simple technique in the thickness measurement project, which can help judge the production phase and status.

- Q: My dad saw an alternative medicine practioner who said he had high levels of aluminum in his blood ... from using aluminum cookware. She said this was causing the shortness of breath and dizziness he was experiencing. Since he has stopped using aluminum cookware, he is now fine. He saw regular doctors, and nobody else could figure out what was wrong with him. Has anyone else out there had any experience with this?

- No but alumimun cookware can cause Alzheimer's

- Q: How do aluminum coils contribute to energy-efficient appliances?

- Aluminum coils play a key role in enhancing the energy efficiency of appliances. The use of aluminum in coil form allows for efficient heat transfer, which is essential for appliances that require cooling or heating mechanisms. Firstly, aluminum coils have excellent thermal conductivity. This means that they can quickly absorb and dissipate heat, resulting in more efficient cooling or heating processes. This is especially important in appliances such as refrigerators, air conditioners, and heat pumps, where effective heat transfer is crucial for maintaining the desired temperature. Moreover, aluminum coils are lightweight yet durable, making them an ideal choice for energy-efficient appliances. The lightweight nature of aluminum reduces the overall weight of the appliance, which leads to lower energy consumption during transportation and installation. Additionally, the durability of aluminum ensures a longer lifespan for the appliance, reducing the need for frequent maintenance or replacement. Furthermore, aluminum is highly resistant to corrosion, which is a common issue in appliances that involve contact with water or moisture. By using aluminum coils, manufacturers can ensure the longevity and reliability of the appliance, thus contributing to energy efficiency by reducing the need for repairs or replacements. Lastly, aluminum is a highly recyclable material. Using aluminum coils in appliances promotes sustainability and reduces the environmental impact. By choosing energy-efficient appliances that incorporate aluminum coils, consumers can support the circular economy and contribute to a more sustainable future. In conclusion, aluminum coils greatly contribute to the energy efficiency of appliances. Their excellent thermal conductivity, lightweight yet durable nature, corrosion resistance, and recyclability make them an ideal choice for enhancing the performance and sustainability of energy-efficient appliances.

- Q: Can aluminum coils be used for electrical transmission lines?

- Yes, aluminum coils can be and are commonly used for electrical transmission lines. Aluminum has several advantages that make it a suitable choice for transmission lines. First, aluminum is a lightweight material, which makes it easier and more cost-effective to transport and install. Second, aluminum is a good conductor of electricity, with similar conductivity to copper. Third, aluminum is less expensive than copper, making it a more economical option for long-distance transmission lines. However, there are some challenges associated with using aluminum coils in transmission lines. Aluminum has a lower tensile strength compared to copper, which means that it is more prone to sagging over long distances. Additionally, aluminum has a higher thermal expansion coefficient than copper, which can cause issues with thermal expansion and contraction. Despite these challenges, proper design and engineering can ensure that aluminum coils are used effectively and efficiently in electrical transmission lines.

- Q: What are the different coil handling options available for aluminum coils?

- Some of the different coil handling options available for aluminum coils include coil lifters, coil tongs, coil hooks, coil cradles, coil upenders, and coil cars. These options allow for safe and efficient handling of aluminum coils during transportation, storage, and processing.

- Q: How much fluorocarbon and polyester paint should be used in production of aluminum coil and aluminum-plastic panel?

- In theory, one kilogram paint can spray 6 square kilometers for your required thickness. Then you can calculate the total areas.

- Q: How do aluminum coils contribute to sustainable building practices?

- Aluminum coils contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, meaning that the production and use of aluminum coils have a minimal impact on the environment. Recycling aluminum requires only a fraction of the energy needed to produce new aluminum, reducing greenhouse gas emissions and conserving natural resources. Additionally, aluminum coils are lightweight and durable, making them an ideal choice for sustainable building practices. The lightweight nature of aluminum reduces the load on the building structure, leading to lower transportation costs and energy consumption during construction. Its durability ensures that aluminum coils have a long lifespan, reducing the need for frequent replacements and associated waste generation. Furthermore, aluminum is resistant to corrosion and requires minimal maintenance. This quality contributes to the longevity of buildings, reducing the need for repairs and replacements over time. This not only saves resources but also reduces the overall environmental impact of the building. Moreover, aluminum coils offer excellent thermal conductivity, which can contribute to energy efficiency in buildings. When used as part of insulation systems or in HVAC systems, aluminum coils help to regulate temperature and minimize energy consumption. This can result in reduced energy bills and a smaller carbon footprint for the building. Lastly, aluminum coils can be used in various applications, including roofing, cladding, and ventilation systems. Their versatility allows for creative and innovative design solutions, promoting sustainable building practices by incorporating energy-efficient features and promoting natural ventilation. In conclusion, aluminum coils contribute to sustainable building practices through their recyclability, lightweight and durable nature, resistance to corrosion, thermal conductivity, and versatility. By choosing aluminum coils for construction, we can minimize the environmental impact of buildings, conserve resources, and promote energy efficiency, ultimately leading to a more sustainable built environment.

- Q: The user is inquiring about the possibility of reusing their old aluminum coils or purchasing used ones.

- <p>Yes, you can reuse your old aluminum coils if they are still in good condition and meet the required specifications for your application. Reusing can be cost-effective and environmentally friendly. When buying used coils, ensure they are from a reputable source and have been properly inspected for any damage or wear that could affect performance. It's crucial to verify the coils' integrity and functionality before use to avoid any potential issues in your manufacturing or production process.</p>

- Q: Are aluminum coils more cost-effective compared to other materials like copper?

- Aluminum coils are generally more cost-effective than other materials like copper for several reasons. To begin with, aluminum is a more abundant metal, making it cheaper to produce. Its abundance also results in more stable prices, reducing the likelihood of market fluctuations and further enhancing its cost-effectiveness. Furthermore, aluminum coils have a lower density compared to copper coils, resulting in lighter units. This lighter weight not only reduces costs for transportation and installation but also makes them easier to handle and maneuver during the manufacturing process. In addition, aluminum coils possess excellent thermal conductivity properties, enabling efficient heat transfer. This leads to more efficient cooling or heating systems, resulting in lower energy consumption and operating costs in the long run. Moreover, aluminum exhibits higher resistance to corrosion compared to copper, making it more durable and requiring less maintenance. The longer lifespan of aluminum coils reduces the need for replacements and repairs, further contributing to their cost-effectiveness. Lastly, aluminum coils are recyclable, and the recycling process requires significantly less energy than producing new aluminum. This aspect adds to the overall sustainability and cost-effectiveness of aluminum coils. In conclusion, considering their lower production costs, lighter weight, superior thermal conductivity, increased durability, and recyclability, aluminum coils are indeed a more cost-effective option compared to materials like copper.

- Q: This question asks for the cost of a set of aluminum coils.

- <p>The cost of a set of aluminum coils can vary significantly based on factors such as the current market price of aluminum, the size and thickness of the coils, and the quantity being purchased. As of my last update, the price of aluminum fluctuates with the global commodities market, and it's best to check with suppliers or on metal exchange platforms for the most accurate and up-to-date pricing. For specific projects, you might need to contact aluminum suppliers directly to get a quote tailored to your requirements.</p>

Send your message to us

Color Aluminum Coil Prepainted-1/3/5xxx

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords