Best Aluminum Coil Slitter Quotes for Ceiling Roofing Mill Finished

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Coil for Ceiling Roofing Mill Finished

Thickness: 0.1mm-10mm

Regular Thickness:0.1mm/0.2mm/0.25mm/0.3mm/0.6mm/0.8mm/1.0mm/1.2mm/1.5mm/2.0mm/3.0mm...

Width: 20mm-2500mm

Inner Diameter: 505mm 508mm 605mm

Material:1050,1060,1070,1100,1200,3003,3004,3005

Temper: O,H12,H14,H16,H18,H22,H24,H26,H32,H34,H36,H38,H111,H112

Surface: mill finish

Packing: Export standard wooden pallets

Payment Terms: 100% irrevocable L/C at sight or 30% T/T in advance as deposit,70% balance against the B/L copy

MOQ: 5000kg

Delivery time: 15-25 days after receiving L/C or deposit

Remark: Specific requirement of alloy grade, temper or specification can be discussed at

your request

2. Application of Aluminium Coil for Ceiling Roofing Mill Finished

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminium Coil for Ceiling Roofing Mill Finished

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

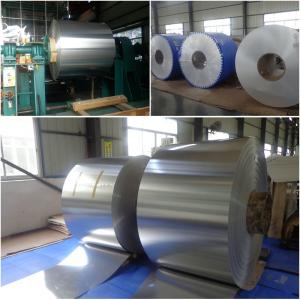

5. Image of Aluminium Coil for Ceiling Roofing Mill Finished

6. Package and shipping of Aluminium Coil for Ceiling Roofing Mill Finished

eye to sky

eye to wall

with wooden pallet (wooden case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2) What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What substances are used to make aluminum coils?

- <p>Aluminum coils are made from aluminum, a lightweight and malleable metal with the chemical symbol Al. They are typically produced from high-purity aluminum or aluminum alloys, which may include small amounts of other elements to enhance specific properties such as strength, durability, or resistance to corrosion. Pure aluminum is soft and lacks strength, so alloys are often used to improve these characteristics for various applications.</p>

- Q: Its got probably 330 horses right now with aluminum heads what do you think it be approx.

- depends on the heads, what mods have been done to them

- Q: I have a muffin pan made of aluminum foil and I do not know if i can put it in the oven to cook some muffins. Many sights say it will melt but they say that about putting a sheet of foil at the bottom of the oven for a long time. I just want it to be in their for half an hour to make muffins.

- Aluminum melts at 1220 degrees F (or around 660 degrees C) [from Wikipedia]. If you are cooking anything at that temperature, you are crazy and have a monster oven. So yeah, no problem with that.

- Q: What is the typical heat transfer coefficient for aluminum coils?

- The typical heat transfer coefficient for aluminum coils depends on various factors such as the specific application, geometry of the coil, and the surrounding conditions. However, in general, aluminum has a relatively high thermal conductivity, making it an efficient conductor of heat. For forced convection applications, where a fluid such as air or water is used to transfer heat, the heat transfer coefficient for aluminum coils can range from 10 to 100 W/m^2K. This range is influenced by factors such as the flow rate, velocity, and temperature difference between the coil and the fluid. In natural convection scenarios, where heat transfer occurs due to the buoyancy-driven flow of air, the heat transfer coefficient for aluminum coils is typically lower, ranging from 5 to 25 W/m^2K. This lower coefficient is due to the slower movement of air and the reduced heat transfer effectiveness compared to forced convection. It is important to note that these values are general guidelines and can vary significantly depending on specific design considerations, material properties, and operating conditions. Therefore, it is recommended to consult specific heat transfer data or conduct detailed experiments or simulations to determine the precise heat transfer coefficient for a given aluminum coil application.

- Q: Can aluminum coils be used in refrigeration systems?

- Indeed, refrigeration systems can utilize aluminum coils. The rationale behind selecting aluminum as the preferred material for coil construction in refrigeration systems stems from its remarkable heat transfer capabilities and resistance to corrosion. Not only are aluminum coils lightweight and long-lasting, but they also excel in efficiently transferring heat, rendering them appropriate for a wide range of refrigeration applications, including air conditioning units, refrigerators, and freezers. Moreover, aluminum coils offer the advantage of being easier to mold and install in comparison to alternative materials, thus solidifying their position as the top choice among manufacturers.

- Q: What are the standard widths of aluminum coils?

- The standard widths of aluminum coils vary depending on the industry and application, but common widths range from 12 inches to 60 inches.

- Q: How do aluminum coils compare to titanium coils in terms of weight?

- Aluminum coils are generally lighter in weight compared to titanium coils.

- Q: This question asks about the impact of aluminum coils on cooking equipment, including their role in heat distribution and potential benefits or drawbacks.

- <p>Aluminum coils in cooking equipment play a significant role in heat distribution and retention. They are known for their excellent thermal conductivity, which allows for even heat distribution across the cooking surface, reducing hot spots and ensuring consistent cooking results. Aluminum's lightweight and malleability also make it easy to shape into various forms, fitting different types of cookware. However, aluminum can react with acidic foods, potentially altering the taste or releasing small amounts of aluminum into the food, which some studies suggest could have health implications. Additionally, aluminum cookware requires careful handling to avoid scratches that can compromise its performance and appearance.</p>

- Q: What is the thickness tolerance of aluminum coils?

- The thickness tolerance of aluminum coils can vary depending on the specific grade and manufacturing process. Generally, the standard thickness tolerance for aluminum coils is around +/- 0.005 inches (+/- 0.13 mm). However, it is important to note that this tolerance can be further refined or adjusted based on the customer's specific requirements and the capabilities of the manufacturer. Some specialized aluminum coil manufacturers may offer even tighter thickness tolerances, typically around +/- 0.002 inches (+/- 0.05 mm), to meet more precise or demanding applications. It is always recommended to consult with the manufacturer or supplier to ensure the desired thickness tolerance is met for a particular project or application.

- Q: What is the typical conductivity of aluminum coils?

- Aluminum coils exhibit a relatively high typical conductivity, with a range of values between 34 and 38 million Siemens per meter (MS/m) at room temperature. Renowned for its exceptional electrical conductivity, aluminum finds extensive application in diverse electrical uses such as power transmission lines, electrical conductors, and coils. This notable conductivity enables the smooth and efficient flow of electric current through aluminum coils, rendering them apt for dependable and efficient electricity conduction.

Send your message to us

Best Aluminum Coil Slitter Quotes for Ceiling Roofing Mill Finished

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords