Aluminium Circle/Aluminium Plate Circle Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

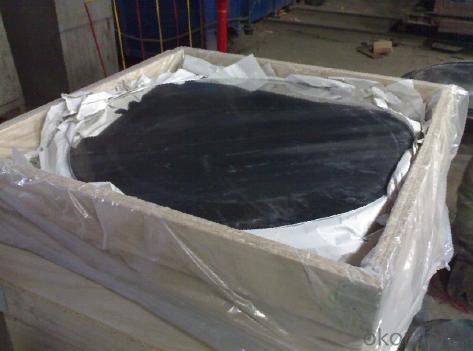

Aluminium Circle/Aluminium Plate Circle Supplier

Parameters

Aluminum Circle and Disc:

Quality Standard:AS Per GBT,ASTM,and BSEN

Grade:1050,1060,1070,1100,1200,3003,5052,

Thickness: as your requirmets

Thickess | As your request |

| alloy | 1050,1060,1100,1200,5005,5052 |

| Temper | H12.H14.H16.H18. H24. H26.O |

| Loading | 24 tons in 1x 20 GP container |

Dimensions | can be produced according to your specifications |

Advantage | Though smelting, casting, hot-rolling, cold-rolling, heat-treatment, finishing and other rechnology, the heavy melting alminium and an appropriate quality of alloying elements is processed to light nonferrous metal material which has the characters of fine luster, good looing, light weight, poisonless and smellessncss, and it also has good propertles of transmitting electric current and heat, processing and corrosion-resisting Applicability |

Application | The product is widely used in cold-extrusion ,Reflector,Traffic sign or deeply-drawing for making electric rice cookers, non-stick pans/pots, kitchens,cookware,cooking-utensil |

Packing detail | Export standard package,bundled or be required. The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 40ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM |

FAQ

Q: Can you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest catalogue?

A: Yes, it will b.e sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, D/A, D/P, T/T, West Union,etc

- Q: Does the SolidWorks mechanical design engineer paint parts individually or draw parts in an assembly?

- There are two ways, corresponding to "bottom up" and "top down" two design methods.

- Q: Force calculation is in the component diagram, the size of the component is obtained by force, and if you don't draw the parts first, how do you draw the general plan?How do you calculate the force of a part if you draw the part diagram first and don't know the size relation between the parts?

- First draw a diagram, determine the location of each part, then draw the parts drawing, and finally the general drawing

- Q: What are the key factors in designing mechanical parts?

- 1- reliability. For example, the design of a transmission shaft, to consider whether the uniform load or impact load, axial load or radial load or both, or combined force. In general, even small loads can be fitted with clearance or transition fit, and tolerances can be enlarged so that processing costs are low. For high speed or large load or impact loads, interference fit should be used, such as flywheel shaft of diesel engine.

- Q: How to design the power assisted robot, mechanical structure and pneumatic part, please point out, thank you!

- 1. pneumatic manipulator mechanical structure can complete the upper, lower, left, right two directions of movement and clamping, pass, to the sub bar, FA pass, looking for Witkey is too simple

- Q: Write the XX in the code for the detail column of the assembly drawingThe company's standard clerk says that the standard number or pattern code can only be used in the code bar. The part XX of my presentation is a part of the assembly drawing, which is a non-standard part. I wonder what standard to fill in Is it the material standard? But the material, Q235B, has been written in the material column.

- Agree upstairsYou write that part of your code ah, is their own parts produced by the company to write the parts of the drawing number, is the procurement of non-standard parts, the supplier to write the parts number.

- Q: including design originality, manufacturing process, drawing, processing technology, cost calculation, and function

- That thing has to be paid for, no white lunch. Besides, you say that is a set of design scheme, sometimes involving intellectual property rights of enterprises / if you are the designer, the graduation design, I can tell you sorry, nobody will give you, at least I don't, those things are all mechanical design personnel spent a long time with a lot of effort to get out of the way they want to.

- Q: How to write the machining process design of machine parts?

- According to each process that the part needs to be processed, the processing technique is determined. The so-called processing technology, that is: the processing of each process, the processing required to what extent?. If the text is not clear, you can draw the technical drawings to illustrate.

- Q: I would like to open a small mechanical design company (specializing in the design of mechanical parts, etc.) can you make money?

- Really, the scope of the company's experience is not the design parts ah, better product design! Do you mean the standard parts? There are regular standard parts factory, if it is an industrial design company, that includes product appearance and internal structure design, it can not just design machinery products.If in Beijing, the best fixed source of the project, otherwise it is difficult to survive, the small Beijing design companies have as many as ten, the most famous is "Rococo" design, development of other city is not clear, but the design development in the south is better, the project will also, in Shenzhen for the.

- Q: What is the design procedure of mechanical parts urgently ah?!

- 5. assembly and parts diagram design. According to the structure and size of parts assembly sketches to determine the complete assembly and parts diagram design. (according to the plan to determine the main dimensions, structure design, parts drawing, sorting out the map) four, as the case with technical documentation requirements, design and coding machine calculation manual, manual, standard parts list, purchased parts list, etc. in the conditions of acceptance in the design process, such as a link the problem is feasible or not, need to return to revise the previous design, until the problem is solved. Sometimes, for this reason, even the whole project has to be knocked over. Therefore, the mechanical design process is an iterative process. (standard and outsourcing parts arrangement, specification preparation, acceptance documents

- Q: Good mechanical design or good mechanical manufacturing?

- The range of mechanical design and manufacturing involves relatively wide, including both mechanical manufacturing and automation;

Send your message to us

Aluminium Circle/Aluminium Plate Circle Supplier

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 50000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords