Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

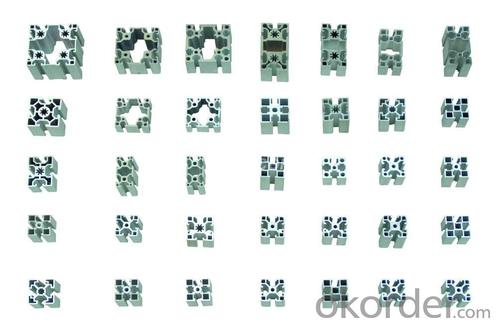

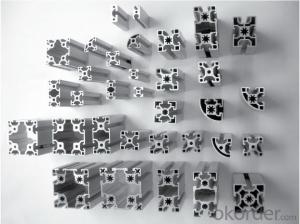

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks about the various types of aluminum profiles that are utilized in the construction of insulation systems.

- <p>Aluminum profiles used for building insulation come in various types, each serving specific functions. These include: 1. Insulation profiles, which provide a thermal barrier; 2. Structural profiles, used for structural support; 3. Cover profiles, which protect the insulation material; 4. Joint profiles, used for sealing joints; 5. Corner profiles, for reinforcing corners; 6. Edge profiles, for finishing edges; and 7. Special profiles, designed for specific applications. Each type is engineered to enhance thermal efficiency and structural integrity in building insulation systems.</p>

- Q: This question asks if there are any health hazards linked to handling aluminum profiles.

- <p>Generally, working with aluminum profiles does not pose significant health risks. Aluminum is a lightweight, corrosion-resistant metal that is widely used in various industries. However, inhalation of aluminum dust or fumes over long periods may cause respiratory issues. Workers should use appropriate personal protective equipment (PPE) such as masks and gloves to minimize exposure. Additionally, aluminum can cause skin irritation in some individuals, so skin contact should be avoided. It's important to follow safety guidelines and maintain good hygiene practices when working with aluminum profiles.</p>

- Q: Can aluminum profiles be used for shopfitting and retail displays?

- Certainly, shopfitting and retail displays can absolutely utilize aluminum profiles. Aluminum, being a versatile material, possesses the advantageous combination of lightweight properties with remarkable strength, making it an ideal choice for constructing structures and fixtures in retail spaces. The customization and fabrication of aluminum profiles are effortlessly achievable, enabling the creation of tailored designs to meet specific requirements, thus allowing for the utmost flexibility in developing diverse display and shopfitting solutions. Moreover, the sleek and contemporary aesthetic offered by aluminum profiles is frequently sought after in retail environments. Furthermore, their exceptional durability and resistance to corrosion guarantee their enduring presence in areas with high foot traffic. Overall, due to their versatility, strength, customization options, and aesthetic appeal, aluminum profiles are an exceptional selection for shopfitting and retail displays.

- Q: Do aluminum profiles require regular maintenance?

- Yes, aluminum profiles do require regular maintenance. This typically involves cleaning them periodically to remove dirt, dust, and other debris that can accumulate on the surface. Additionally, it is important to check for any signs of damage or wear, such as corrosion or loose fittings, and address them promptly to ensure the longevity and functionality of the aluminum profiles.

- Q: What screws do you use for aluminum alloy profiles?

- Aluminum alloy profiles are generally: with electric nails, self tapping screws fixed. Do not use ordinary screws, tools should also be chosen.Self tapping screws are used for non metal or soft metal, without backing holes and tapping; self tapping screws are pointed, so that they can be self tapping; ordinary screws are flat head, and the thickness is the same.Classification of aluminium alloy sections by use:Construction aluminum profiles (divided into two types of doors and windows and curtain wall).Radiator aluminum profile.General industrial aluminum: mainly used in the manufacture of industrial production, such as automation equipment, covering the skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, shelves and so on, electronic machinery industry and clean room with.Aluminum alloy profile of railway vehicle structure: mainly used for rail vehicle body manufacturing.

- Q: Can aluminum profiles be used in display stand and podium manufacturing?

- Yes, aluminum profiles can definitely be used in display stand and podium manufacturing. Aluminum is a highly versatile and durable material that offers several advantages such as lightweight, corrosion resistance, and easy customization. It can be easily shaped and fabricated into various designs and sizes, making it suitable for creating aesthetically appealing and functional display stands and podiums. Additionally, aluminum profiles can also be an excellent choice for portable or temporary setups due to their portability and easy assembly.

- Q: Is it possible to utilize aluminum profiles as a material for exterior wall cladding?

- <p>Yes, aluminum profiles are commonly used for exterior cladding due to their durability, low maintenance, and resistance to corrosion. They are lightweight, easy to install, and can be designed in various shapes and sizes to suit architectural requirements. Additionally, aluminum profiles offer excellent weather resistance and can be painted or anodized to provide a protective finish and aesthetic appeal.</p>

- Q: What is the relationship between aluminum alloy and aluminum alloy?

- First, according to use can be divided into the following categories: 1. building doors and windows, aluminum doors and windows [1] (divided into two windows and curtain walls). Special aluminum radiator 2. CPU radiator 3. Aluminum Alloy shelf aluminum profile, the difference between them is that the different cross-sectional shapes. They are produced by hot melt extrusion 4.. Industrial aluminum: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with the majority!

- Q: Are aluminum profiles suitable for outdoor sign applications?

- <p>Yes, aluminum profiles are commonly used for outdoor signage due to their durability, resistance to corrosion, and lightweight properties. They can withstand various weather conditions without rusting or fading, making them an ideal material for long-lasting outdoor signs. Aluminum profiles can be easily cut, shaped, and assembled, offering flexibility in design and functionality.</p>

- Q: Can aluminum profiles be subjected to painting or coating processes to enhance their aesthetic appeal and longevity?

- <p>Yes, aluminum profiles can be painted or coated to improve their appearance and durability. The process usually involves cleaning the aluminum to remove any contaminants, followed by a conversion coating to enhance adhesion. After that, a primer is applied, and finally, the paint or coating is applied. This not only enhances the visual appeal but also protects the aluminum from corrosion and wear, extending its lifespan.</p>

Send your message to us

Schuco Aluminum Profiles for Sliding Window

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords