Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

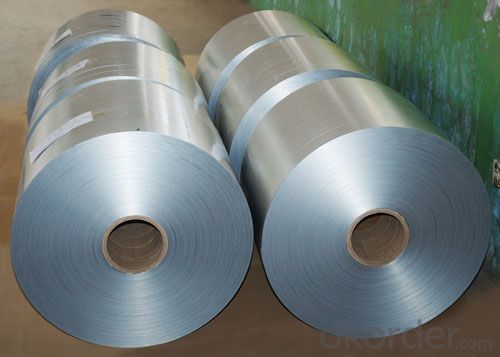

Alloy Embossed Aluminium Plate/Sheet 1050 1060

Packaging & Delivery

| Packaging Details: | Standard seaworthy packages in bundles or as per requirement. Container size: The inner size of container is below: 20ft GP: 5.8m(length) x 2.13m(width) x 2.18m(high) about 24-26CBM 4 0ft GP: 11.8m(length) x 2.13m(width) x 2.18m(high) about 54CBM 40ft HG: 11.8m(length) x 2.13m(width) x 2.72m(high) about 68CBM(stainless steel seamless pipe) |

| Delivery Detail: | Within 5-15 days after deposit(price of aluminum coil) |

Our Services

1. Provide products with high quality and reasonable price

2. The first time back to you

3. Perfect after-sale service

4. Small order is acceptable

5. OEM is acceptable

6. 12Months quality guarantee

7. Any third party testing is acceptable

Product Description

| Product Name | Prices of aluminum coil |

| Standard | JIS, AISI, ASTM, GB, DIN |

| Alloy | Yes |

| Width | 720-1250mm or as the customers' requirements |

| Length | 10000-12000mm mm or as the customers' requirements |

| Thickness | 0.12-1.5mm |

| Surface | Black painted,PE coated,GL,color coated,etc |

| Item | steel plate,steel sheet,alloy plate,alloy sheet |

| Application | construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields ,etc. |

| Packing | Export standard or as customers' requirement |

| Delivery time | Within 7 working days, according to customers' quantities |

| Payment | L/C or T/T or as customers' requirement |

| MOQ | 1 Ton |

| Quality | High Quality. We can Provide SGS inspection if you need . |

| Productivity | 60000 Tons/Month |

| Attention | We will supply you good quality and bottom price and first-class service in china and hope to be your golden supplier |

- Q: What are the potential applications of coil-embossed aluminum coils?

- Coil-embossed aluminum coils have a wide range of potential applications due to their unique features and properties. Here are some of the potential applications: 1. Building and construction: Coil-embossed aluminum coils can be used in the construction industry for various purposes. They can be used as roofing materials, wall cladding, and exterior decorative panels. The embossed pattern provides aesthetic appeal and enhances the overall appearance of the building. Additionally, the corrosion-resistant properties of aluminum make it a durable choice for outdoor applications. 2. Automotive industry: Coil-embossed aluminum coils find applications in the automotive industry. They can be used for manufacturing body panels, trims, and decorative elements for vehicles. The embossed surface adds texture and style to the automotive components while providing durability and resistance to wear and tear. 3. Appliances and electronics: The embossed patterns on aluminum coils make them suitable for use in appliances and electronics. They can be used for manufacturing refrigerator panels, microwave casings, and other household appliances. The textured surface can also enhance the grip on handheld electronic devices. 4. Packaging industry: Coil-embossed aluminum coils have potential applications in the packaging industry. They can be used for manufacturing packaging materials such as cans, containers, and lids. The embossed surface can provide a unique branding opportunity, allowing companies to create visually appealing packaging designs. 5. Signage and advertising: The embossed patterns on aluminum coils can be utilized in the signage and advertising industry. They can be used for manufacturing outdoor signs, billboards, and display panels. The embossed surface adds depth and dimension to the signage, making it more eye-catching and attractive. 6. Furniture and interior design: Coil-embossed aluminum coils can be used in the furniture and interior design industry. They can be used for manufacturing decorative panels, furniture trims, and accents. The embossed patterns can add a touch of elegance and uniqueness to furniture and interior spaces. 7. Renewable energy: Aluminum is a lightweight and corrosion-resistant material, making it suitable for renewable energy applications. Coil-embossed aluminum coils can be used for manufacturing solar panels and wind turbine components. The embossed surface can enhance the efficiency of solar panels by increasing light absorption and reducing reflection. Overall, coil-embossed aluminum coils have a wide range of potential applications across various industries. The embossed patterns, along with the inherent properties of aluminum, make them a versatile material choice for both functional and aesthetic purposes.

- Q: What are aluminum coils used for?

- Aluminum coils are commonly used in various industries, such as construction, automotive, and HVAC, for their excellent thermal conductivity and corrosion resistance properties. They are primarily used for manufacturing heat exchangers, air conditioning systems, refrigeration units, and other heat transfer applications.

- Q: I can't figure out what the metabolic role of aluminum is. Been searching for a while and can't seem to find anything concrete.If you can, please include sources. Thanks!

- I okorder /

- Q: This question asks for a comparison of the benefits and drawbacks associated with using aluminum coil.

- <p>Aluminum coil offers several advantages such as high strength-to-weight ratio, corrosion resistance, and excellent thermal and electrical conductivity. It is also cost-effective and easy to form, making it ideal for various applications like construction, automotive, and electrical industries. However, it has some disadvantages, including lower strength compared to steel, potential for galvanic corrosion when in contact with dissimilar metals, and a higher likelihood of denting or denting. Additionally, aluminum's recycling process can be energy-intensive, which may impact its environmental sustainability.</p>

- Q: Can aluminum coils be insulated?

- Yes, aluminum coils can be insulated. Insulation is commonly applied to aluminum coils to improve energy efficiency and prevent condensation and heat loss in various HVAC systems.

- Q: How do aluminum coils contribute to energy-efficient insulation?

- Aluminum coils play a crucial role in enhancing energy-efficient insulation in various ways. Firstly, aluminum is an excellent conductor of heat, meaning it can effectively transfer heat away from the source, reducing the amount of heat that penetrates into the insulated space. This property helps to maintain a stable and comfortable indoor environment while minimizing the need for excessive heating or cooling. Additionally, aluminum coils are often utilized in the construction of air conditioning and refrigeration systems, where they act as the heat transfer medium. By efficiently absorbing and dissipating heat, these coils enable the system to cool down the air more rapidly, thus reducing energy consumption and enhancing overall energy efficiency. Moreover, aluminum is a lightweight material, which makes it easier to handle and install in insulation systems. This lightweight characteristic allows for more flexibility and ease of transportation during the manufacturing and installation processes, resulting in cost and energy savings. Furthermore, aluminum coils are highly corrosion-resistant, ensuring their longevity and preventing the degradation of insulation performance over time. This durability translates into long-term energy efficiency, as the insulation system remains effective for an extended period without requiring frequent maintenance or replacement. In summary, aluminum coils contribute to energy-efficient insulation by efficiently conducting heat, facilitating rapid cooling in air conditioning systems, reducing energy consumption, being lightweight and easy to handle, and providing long-lasting performance due to their corrosion resistance. These characteristics make aluminum coils a favorable choice for enhancing energy efficiency in insulation applications.

- Q: I wrap everything with aluminum foil and bake it in the oven -- fish, meat, vegetables. Is this really safe? Or safe when done occasionally? Or should I find a new way?

- I use aluminium foil often for baking however I use baking paper between the food and the foil. I am sure it is safe to use foil, however I find that on occasions the foil sticks to the food, so I use the non stick paper between. I hope this helps.

- Q: How are aluminum coils used in the construction industry?

- Aluminum coils are widely used in the construction industry due to their numerous beneficial properties. These coils are primarily employed in the fabrication of various building components, such as roofs, facades, gutters, and cladding systems. One of the main advantages of using aluminum coils in construction is their lightweight nature. Aluminum is significantly lighter than other commonly used metals like steel, making it easier to handle and install. This lightweight property also reduces the load on the building structure, allowing for more flexibility in design and minimizing the overall construction costs. Furthermore, aluminum coils offer exceptional corrosion resistance. Aluminum naturally forms a protective oxide layer on its surface, which prevents it from rusting or deteriorating when exposed to moisture or harsh environmental conditions. This corrosion resistance ensures the longevity and durability of the building components, reducing maintenance and replacement costs in the long run. Aluminum coils are also highly malleable and can be easily formed into various shapes and sizes. This versatility allows architects and engineers to create innovative and aesthetically pleasing designs. Aluminum coils can be bent, folded, or molded to fit any architectural requirement, enabling the construction of unique and visually appealing structures. In addition, aluminum is an excellent conductor of heat and electricity. This property makes aluminum coils ideal for applications that require efficient thermal or electrical conductivity. For example, aluminum coils are often used in HVAC systems to transfer heat or in electrical wiring to ensure optimal performance. Moreover, aluminum is a sustainable and environmentally friendly material. It is 100% recyclable without losing its properties, making it a perfect choice for sustainable construction practices. The recyclability of aluminum coils reduces waste generation and conserves natural resources, contributing to a greener and more sustainable construction industry. In conclusion, aluminum coils are extensively used in the construction industry due to their lightweight nature, corrosion resistance, malleability, efficient conductivity, and sustainability. These coils facilitate the construction of durable, aesthetically pleasing, and energy-efficient buildings while reducing costs and environmental impact.

- Q: Can aluminum coils be used in the manufacturing of medical devices?

- Yes, aluminum coils can be used in the manufacturing of medical devices. Aluminum is a versatile material that offers several advantages for medical device manufacturing. It is lightweight, corrosion-resistant, and has good thermal conductivity. These properties make aluminum coils suitable for various medical applications such as medical imaging equipment, surgical instruments, and prosthetics. Medical imaging devices, such as MRI and CT scanners, often use aluminum coils to transmit and receive electromagnetic signals. Aluminum's electrical conductivity allows for efficient signal transmission, enhancing the accuracy and quality of medical imaging. Additionally, aluminum's lightweight nature makes it easier to handle and maneuver during medical procedures. Aluminum coils are also used in the manufacturing of surgical instruments. These instruments require materials that are sterilizable, durable, and have high strength. Aluminum meets these requirements, as it can be easily sterilized using various methods, including steam, ethylene oxide, or gamma irradiation. Its durability ensures that the instruments can withstand repeated sterilization cycles without degradation, and its high strength ensures the instruments can withstand the forces applied during surgical procedures. Moreover, aluminum can be employed in the production of prosthetics, such as artificial limbs. Aluminum's lightweight nature makes it an ideal material for creating prosthetic devices that are comfortable for patients to wear and move around with. Additionally, its corrosion-resistant properties make it suitable for long-term use, as it can withstand exposure to body fluids and environmental factors. Overall, aluminum coils can indeed be used in the manufacturing of medical devices. Their lightweight, corrosion-resistant, and electrically conductive properties make them a valuable material for medical applications, contributing to the development of advanced and reliable medical devices.

- Q: This question asks about the environmental effects associated with the use of aluminum coils.

- <p>The environmental impacts of using aluminum coils include energy consumption during production, potential release of greenhouse gases, and waste generation. Aluminum production requires significant energy, contributing to carbon emissions. Additionally, the extraction of bauxite, the primary source of aluminum, can lead to habitat destruction and water pollution. However, aluminum is highly recyclable, and recycling it saves energy and reduces waste. Proper disposal and recycling practices can mitigate some of these impacts, making aluminum a more sustainable choice when managed correctly.</p>

Send your message to us

Terra Bronze Aluminum Coil - Alloy Embossed Aluminum Plate/Sheet 1050 1060

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords