Al-Zinc coated Steel Rolled Coil for Steel Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

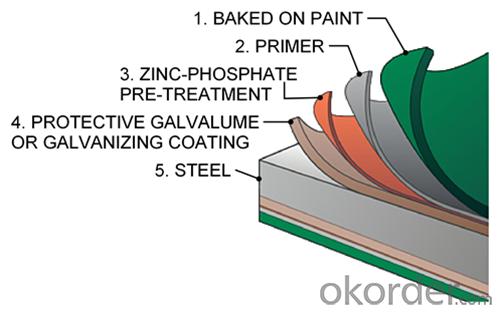

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 50 tons | 50 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What are the different types of steel processing techniques for coils?

- There are several types of steel processing techniques for coils, including hot rolling, cold rolling, annealing, pickling, and galvanizing.

- Q: How are galvanized steel coils different from regular steel coils?

- Galvanized steel coils differ from regular steel coils in terms of their protective coating. Galvanized steel coils are coated with a layer of zinc, which provides a protective barrier against corrosion and rust. This process, known as galvanization, involves dipping the steel coils into a bath of molten zinc or applying zinc onto the surface through various methods. Regular steel coils, on the other hand, do not have this protective coating, making them more susceptible to corrosion and rust. The zinc layer on galvanized steel coils not only acts as a physical barrier but also provides sacrificial protection, meaning that if the coating gets scratched or damaged, the zinc sacrifices itself to protect the underlying steel from corrosion. This makes galvanized steel coils highly durable and suitable for applications that require resistance to harsh environmental conditions, such as outdoor construction projects, automotive manufacturing, and the production of household appliances.

- Q: I would like to know if steel is basically a very dense crystal, or if it is a different atomic structure

- Steel is crystalline. In general the bigger the crystals the better.

- Q: How are steel coils used in the production of roofing and siding?

- Steel coils are used in the production of roofing and siding by being processed and formed into flat sheets or panels. These coils are run through a roll forming machine, which shapes them into the desired profile for roofing or siding. The resulting sheets or panels are then cut to size and installed on buildings to provide durable and weather-resistant protection.

- Q: What are the common applications of coated steel coils?

- Some common applications of coated steel coils include manufacturing of automotive parts, construction materials such as roofing and siding, appliances, and electrical equipment. They are also used in the production of household goods such as furniture, shelving, and storage racks. Additionally, coated steel coils find applications in the transportation industry for manufacturing trailers, shipping containers, and railway cars due to their durability and corrosion resistance.

- Q: How are steel coils protected from chemical damage?

- Steel coils are typically protected from chemical damage through the application of a protective coating or by storing them in a controlled environment to prevent exposure to corrosive substances.

- Q: How are steel coils inspected for quality?

- Steel coils are inspected for quality through various methods such as visual inspection, dimensional measurement, and non-destructive testing techniques. These inspections ensure that the coils meet specific quality standards and requirements by examining their surface condition, dimensions, and internal integrity.

- Q: How are steel coils used in the manufacturing of metal furniture?

- Steel coils are used in the manufacturing of metal furniture as they provide the raw material for forming different components, such as frames, legs, and support structures. These coils are processed and shaped through various manufacturing techniques like cutting, bending, and welding to create the desired furniture pieces. The strength, durability, and versatility of steel make it an ideal material for metal furniture, ensuring stability and longevity in the final products.

- Q: I mean 4 inch thick steel like was used in the WTC buildings, especially WTC 7 which did not get hit by a plane. Can carpeting, desk chairs, water coolers and dry erase boards burn hot enough and long enough to melt steel that is normally made in a blast furnace?

- Gavin, the danger posed by steel columns and girders during a fire in a building, is not the danger of the steel melting but of the steel expanding and snapping the bolts that hold all of the steel together. Very high temperatures can be achieved in a building fire because the up-draft caused by the rising hot air, delivers a massive amount of oxygen to the burning carpet, paper and furniture. When a steel frame office tower burns, the heat expands the steel and snaps the bolts. This causes the building to fall-down and not necessarily, burn-down. I am too lazy to look-up the melting point of steel but it is not very high. That is one reason for the columns and girders in steel framed buildings, to be covered in asbestos (which is a fatally toxic material) or magnesium di-oxide.

- Q: A 100 kg solid steel ball with a radius of 5 m is being spun on ice with an angular velocity of 5 rev/s pointed into the ice (clockwise rotation when viewed from above).A student shoots a 10 kg marble at the steel ball. The marble hits the ball along its side as shown with an initial velocity of 5 m/s to the left. If, right after the collision, the final velocity of the marble is 2.5 m/s to the left, what is the angular velocity of the steel ball after the collision?

- You need to do conservation of angular momentum about the steel ball's axis. Angular momentum = I.ω The steel ball's initial ω = 5 rev/s = 5*2pi rad/s = 31.4 rad/s The steel ball's moment of inertia I = (2/5)*m*r^2 = 40*25 kg.m^2 = 1000 kg.m^2 The marble's initial ω = v / r where r is the perpendicular distance from the steel ball's axis You need to look at the diagram for this. The marble's I about the steel ball's axis is I = m*r^2 where r is the same as above. (marble is treated as a point mass). Then work out the total initial ang. momentum = final ang. momentum and solve for ω...

Send your message to us

Al-Zinc coated Steel Rolled Coil for Steel Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords