Al-Zinc Coated Steel Rolled coil for steel Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

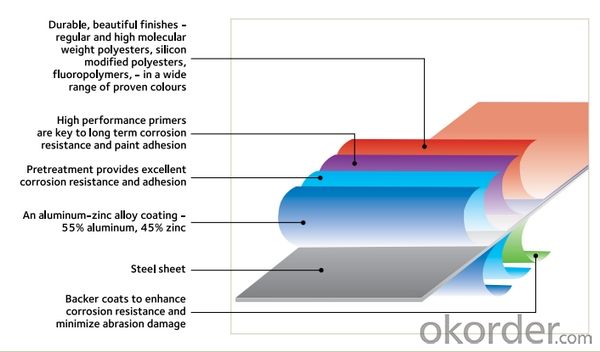

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

Aluminum zinc coils is a kind of coated steel coil/sheet. With the cold rolled steel of different strength and thickness as substrate, it is produced through applying Al-Zn coat on both faces by hot dip process. In its coating, Al accounts for about 55%, Si 1.6%, while the remaining is Zn. Aluminum zinc coils enjoys both the physical protective feature and durability of Al and the electrochemical protective property of Zn. And its surface has bright silver color and regular embossed-like figure, which are highly decorative.

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Want to get stainless steel sink. I want quality, durability, quiet, etc. Any suggestions??

- One part of our home is the kitchen, which is usually one of the busiest parts of the home. And part of it is the kitchen sink; as you look at the sink, you can hardly tell how much work is done in the sink. And in our daily activities, most of us use our sink in our own personal needs. Most of the time, we wash our face and clean our clothes, shoes and anything that needs to be washed in our sink. With this kind of job that the sink is going through in its everyday life, sink must be tough enough to take all the pressure of its job. Ordinary sink will not last long when it is use regularly. It may acquire rust, scratches and dent as we have use it in a regular basis, this is why we need to look for a sink that can manage to handle different usage and tasks in our home. In choosing a sink for our home, we must consider the quality and not the price alone. Stainless steel sink is easy to clean; stain and rust are needed not to worry because stainless steel sink is proven a rustproof material. But of course proper care for the sink should always be taken care of to make use of the sink for a very long time. In shopping for a sink, it can be hassle knowing that stainless steel sink is made of heavy material. And the good news is that stainless steel sink can be bought online. You can shop through the internet and you can have the freedom to choose a sink that will fit your kitchen.

- Q: Hi,Well, I live near almost across the street from a forest, and my neighborhood is full of raccoons!!! Recently, I just purchased a bunny and have kept it at my cousin's house for the time being. He has a steel cage, and is about 6 months old. I am considering bringing him home and leaving him in the back yard with his steel cage. I am just afraid that raccoons can bite through the steel and get to him. So the question is... Is is possible for raccoons to bite through steel? Btw,Please don't answer hate comments about me being a bad rabbit owner. I simply want to know if raccoons can bite through steel. If it doesn't work out, the rabbit will stay at my cousins house until further notice. But please, I did not waste 5 points for unneeded answers. Thanksss!

- Well the raccoons can't bite through steel unless it is very thin steel, like aluminum foil thickness. But they have long arms and can reach into the cage so that would be my worry. They are also very clever so I don't know if it is safe for the bunny. That would depend upon the size of the cage and how hungry the raccoons are. The raccoons might be tempted to try to steal the bunny's food so that is a concern. Check with a pet shop owner or forester or someone like that who has knowledge about raccoons in the area.

- Q: how come when i put steel legs in lowest price in grand exchange no one buys them i got 101 steel legs in there and there at lowest price and they have been there for 3 days

- Rune and Dragon are way better. Nobody uses steel legs, you should get some higher level in magic to high alch them. They bring like 700gp a piece that way

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- Fire, Ground, and Fighting. 2 of the most common moves in the game now (Close Combat and Earthquake) will completely bone steel types.

- Q: How are steel coils used in the production of roofing and siding?

- Steel coils are used in the production of roofing and siding by being processed and formed into flat sheets or panels. These coils are run through a roll forming machine, which shapes them into the desired profile for roofing or siding. The resulting sheets or panels are then cut to size and installed on buildings to provide durable and weather-resistant protection.

- Q: What are the dimensions of steel coils used in the household appliance industry?

- The dimensions of steel coils used in the household appliance industry can vary depending on the specific application and requirements. However, standard dimensions for steel coils commonly used in this industry range from 0.4mm to 3mm in thickness and 600mm to 1500mm in width. The length of the coils can also vary, typically ranging from a few hundred meters to several kilometers. These dimensions ensure that the steel coils are suitable for various household appliance manufacturing processes, such as forming, stamping, and welding. It is important to note that these dimensions are not fixed and can be customized based on the specific needs of the appliance manufacturer.

- Q: What are the different methods of surface treatment for steel coils?

- There are several different methods of surface treatment for steel coils, each with its own benefits and applications. Some of the most common methods include: 1. Hot-dip galvanizing: This is a process where the steel coil is immersed in a bath of molten zinc, which forms a protective coating on the surface. Hot-dip galvanizing provides excellent corrosion resistance and is commonly used in outdoor applications such as roofing, fencing, and automotive parts. 2. Electro-galvanizing: In this method, a thin layer of zinc is electroplated onto the surface of the steel coil. Electro-galvanizing offers similar corrosion resistance as hot-dip galvanizing, but with a thinner coating. It is often used in applications where a smooth and aesthetically pleasing finish is desired, such as appliances, electrical equipment, and automotive components. 3. Powder coating: Powder coating involves applying a dry powder to the surface of the steel coil, which is then cured under heat to form a durable and protective layer. This method provides excellent resistance to chipping, scratching, and fading, making it suitable for a wide range of indoor and outdoor applications. 4. Painting: Steel coils can also be treated with conventional liquid paint coatings, which provide both protection and aesthetic appeal. Paint coatings can be customized to meet specific requirements such as corrosion resistance, UV protection, or chemical resistance. They are commonly used in industries such as construction, automotive, and appliances. 5. Pickling and oiling: This method involves removing any scale or rust from the surface of the steel coil by dipping it in an acid solution (pickling), followed by a coating of oil to prevent reoxidation. Pickling and oiling are typically used for temporary corrosion protection during storage and transportation of steel coils. 6. Pre-painted coatings: Steel coils can be coated with pre-painted finishes at the manufacturing stage. Pre-painted coatings are applied in a continuous process, where the steel coil is passed through a coating line, and a layer of paint is applied. This method provides a wide range of colors and finishes, making it popular in the construction, automotive, and appliance industries. These are just a few of the methods commonly used for surface treatment of steel coils. The choice of method depends on factors such as the desired level of corrosion resistance, aesthetics, environmental conditions, and the specific application requirements.

- Q: How are steel coils used in the production of doors and windows?

- Steel coils are vital components in the production of doors and windows due to their strength and versatility. These coils are typically made from high-quality steel and are used in various stages of the manufacturing process. Firstly, steel coils are used to create the frame of the doors and windows. The coils are unrolled and cut into specific lengths, depending on the desired dimensions of the frame. The steel is then bent and shaped into the required frame design, ensuring that it is strong and durable. Next, the coils are used to produce the panels or glass holders for the doors and windows. The steel is cut and formed into the desired shape, and then it is either welded or attached to the frame. This ensures that the doors and windows have a sturdy structure and can handle the weight and pressure of the glass or panels. Additionally, steel coils are also used to create the hinges and other hardware components of the doors and windows. The coils are cut and shaped into the necessary parts, ensuring that they are strong enough to support the movement and functionality of the doors and windows. Furthermore, steel coils can be used for decorative purposes. They can be embossed or coated with different finishes to enhance the appearance of the doors and windows. This allows for a wide range of design options, enabling manufacturers to create doors and windows that suit various architectural styles and preferences. In summary, steel coils play a significant role in the production of doors and windows. They are used to create the frame, panels, hinges, and other hardware components, ensuring strength, durability, and functionality. Additionally, they can be used for decorative purposes, allowing for customization and aesthetic appeal.

- Q: (I'm not sure if steel is in fact a mineral)But I want to know if .. Last say topaz is stronger/harder then steel

- Mineral ≠ metal Strong ≠ hard Even after you learn what the words mean, the only straight answer is still Look and see.

- Q: I want to know what to my wash stainless fridge door with before applying the stainless steel polish.

- Tips For Cleaning Your Stainless Steel No matter if you are in an industrial kitchen or just your household kitchen, maintaining the look and the cleanliness of your stainless is essential. There are plenty of products on the market that claim to be able to help you, but you can also do just as good with just knowing how to handle it. Stainless steel is difficult to clean because streaks and fingerprints show up easily. It is easier to see grime, grease and fingertips on stainless than on windows. To help you to keep your stainless steal countertops, utensils and appliances clean, follow these basic rules of thumb. Much more at web page!!

Send your message to us

Al-Zinc Coated Steel Rolled coil for steel Roofing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords