Al-Zinc coated steel coil For construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Al-Zinc coated steel coil

Description of Aluminum Zinc Rolled Coil

The detailed information for the Al-Zinc coated steel coil is as following and it is mainly using for roofing producing, making ceiling grid and all kinds of roll forming structure.

Thickness: 0.20mm to 1.20mm

Width: 914mm, 1000mm, 1200mm, 1219mm and 1250mm, or slit narrow strip according to customer request, can be slit from 20mm to 610mm.

Coil ID: 508mm

Coil weight: 3 tons to 6 tons

Thickness tolerance: +/- 0.02mm or according to customer request.

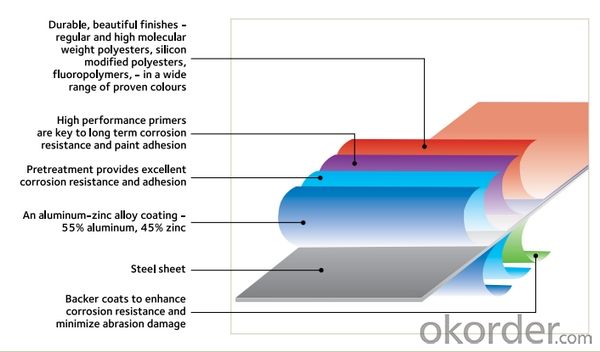

Main Feature of Al-Zinc coated steel coil

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat resistance: Aluminum zinc alloy steel sheet has excellent heat resistance, can withstand high temperatures over 300 centigrade, and is similar with aluminized steel high temperature oxidation resistance. It often used in chimney pipes, ovens, fluorescent lighting device and the device cover.

3. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

4. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Al-Zinc coated steel coil

1. Construction and building: roofing; ventilating duct; handrail; partition panel;etc.

2. Electric appliance: refrigerator; washing machine; refrigerator; DVD;etc.

3.Transportation: oil tank; road sign; etc.

4.Agriculture:barn; etc.

5.Others:vending machine; game machine; etc.

Specifications of Al-Zinc coated steel coil

Prepainted galvanized steel coil ( PPGI ) | Prepainted galvalume steel coil ( PPGL ) | |

Standard | JIS G3312 CGCC | J IS G3322 CGLCC |

Valid thickness | 0. 16 ~1. 2 0mm | 0. 16 ~1. 2 0mm |

Coil width | 600~1250mm | 600~1250mm |

Coil ID | 508mm & 610mm | 508mm & 610mm |

Coil weight | 3~5 tons | 3~5 tons |

Coating | 4 0~275 g/m2 | AZ30 to AZ150 |

Paint t hickness , top side | 15~25 microns | 15~25 microns |

P aint t hickness , reverse | 5~7 microns or 15~25 microns | 5~7 microns or 15~25 microns |

Color | any RAL code | any RAL code |

Package | vertical, eye to sky & horizontal | vertical, eye to sky & horizontal |

MOQ | 25 tons | 25 tons |

FAQ of Al-Zinc coated steel coil

We have organized several common questions for our clients,may help you sincerely:

1. What is the minimum order quantity ?

Our MOQ is 50mt for each size. And we will consider to give more discount if you make big order like 1000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the maximum tension that steel coils can withstand during uncoiling?

- The maximum tension that steel coils can withstand during uncoiling can vary depending on various factors such as the type and grade of steel, the dimensions of the coil, and the uncoiling process. However, steel coils are typically designed to withstand high tension forces, with maximum tensile strengths ranging from 300 to 2,000 megapascals (MPa). It is recommended to consult the manufacturer's specifications or engineering guidelines for precise information regarding the maximum tension limits for a specific steel coil.

- Q: I mean, besides the light weight and other graces of Aluminium and Carbon, Steel frames are absolutely out-dated and they have nothing to do these days... or it is still possible to enjoy a nice ride on our heavy old pals?

- Au contraire; many great bikes are still steelies. Today's steel is much lighter than 10 yrs ago.

- Q: How are steel coils used in the production of storage containers?

- In the production of storage containers, steel coils play a vital role. These coils, manufactured from high-quality steel, are crucial for constructing the walls, floors, and roofs of the containers. To begin the process, the steel coil is uncoiled and passed through a series of machines that cut and shape it into the desired dimensions. Then, the steel is transformed into panels, which are either welded or riveted together to form the container's structure. The strength, durability, and resistance to corrosion make steel coils an excellent material for storage containers. They provide a robust framework that can endure heavy loads and harsh environmental conditions. Moreover, the coils can be easily molded and customized to meet specific size and shape requirements. Once the structure of the container is complete, it is typically coated with a protective layer of paint or other coatings to further enhance its durability and resistance against weather elements. This ensures that the container remains unaffected by moisture, UV rays, and other external factors that could cause deterioration. All in all, steel coils are of utmost importance in the production of storage containers as they offer the necessary strength and durability required to safely store and transport a wide array of goods and materials.

- Q: How do steel coils contribute to the HVAC industry?

- Steel coils are an integral component of the HVAC (Heating, Ventilation, and Air Conditioning) industry and play a crucial role in the functioning and efficiency of HVAC systems. These coils are typically made from high-quality steel, such as stainless steel or galvanized steel, which ensures durability and resistance to corrosion. One of the main ways steel coils contribute to the HVAC industry is by facilitating heat transfer. HVAC systems use coils to transfer heat between the air and a refrigerant. In air conditioning units, for example, the evaporator coil absorbs heat from the indoor air, while the condenser coil releases heat to the outside air. The steel coils in these units provide a large surface area for efficient heat exchange, enabling the cooling or heating of the air as required. Moreover, steel coils also contribute to the overall energy efficiency of HVAC systems. By maximizing heat transfer, these coils allow HVAC systems to operate at optimal performance levels while consuming less energy. This not only helps reduce energy costs for users but also makes HVAC systems more environmentally friendly by minimizing energy consumption and greenhouse gas emissions. Steel coils in HVAC systems also contribute to the quality of indoor air. As air passes over the coils, any impurities, such as dust, dirt, or mold, can accumulate on the coil's surface. Regular maintenance and cleaning of the coils are essential to prevent the buildup of contaminants that could negatively impact air quality. Properly maintained steel coils ensure clean and healthy indoor air, which is particularly important for commercial buildings, hospitals, and other spaces where air quality is crucial. In addition to their heat transfer and energy efficiency capabilities, steel coils also provide durability and longevity to HVAC systems. Steel is a strong and resilient material that can withstand high temperatures, pressure, and environmental stressors. By using steel coils, HVAC systems can operate reliably and efficiently for extended periods, reducing the need for frequent repairs or replacements. Overall, steel coils are a vital component of the HVAC industry. They enable efficient heat transfer, improve energy efficiency, enhance indoor air quality, and provide durability to HVAC systems. Without steel coils, the performance and effectiveness of HVAC systems would be significantly compromised, making them an indispensable element of the HVAC industry.

- Q: Fallout 3 take it back quest?if i am in the rotunda and dont have broken steel installed yet so i cant leave if i instal it will i be able to continue the game even if im seconds away from the end without it Additional Detailsi know it continues on but im not sure if it will let me cause i got this far without it 1 objective away from finishing the quest idk if it will change that little bit so i can continue (ps3)already in the purifier place kill col. autum liek i said just gotta do the code thing to it idk if im to far for broken steel to effect this save file

- Yes. The Broken Steel add-on goes automatically where ever you are. The thing is, I would like stand around the control room for a little while until the Broken Steel add-on is completely downloaded (Basically pop A LOT of rad-x and radaway). You should see a pop-up message saying that Broken Steel is installed and the level cap is now at 30.

- Q: Can steel coils be coated with weather-resistant materials?

- Yes, steel coils can be coated with weather-resistant materials. Coating steel coils with weather-resistant materials helps to protect them from corrosion and other weather-related damages, extending their lifespan and ensuring their durability in various weather conditions.

- Q: What are the different types of steel coil packaging materials?

- There are several types of steel coil packaging materials, including steel strapping, plastic strapping, stretch film, edge protectors, corner protectors, and cardboard tubes.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- I would get a 1095, serrated edge, tanto style, with either a good quality rubberized or bone handle.

- Q: What is the purpose of coating steel coils?

- The purpose of coating steel coils is to provide a protective layer that prevents corrosion and enhances the durability and lifespan of the steel.

- Q: How are steel coils inspected for flatness?

- Steel coils are inspected for flatness using various methods, such as visual inspection, measuring the crown or center buckle, and conducting a straight edge test. These techniques help assess any deviations or unevenness in the coil's surface, ensuring that it meets the required flatness standards.

Send your message to us

Al-Zinc coated steel coil For construction roof

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords