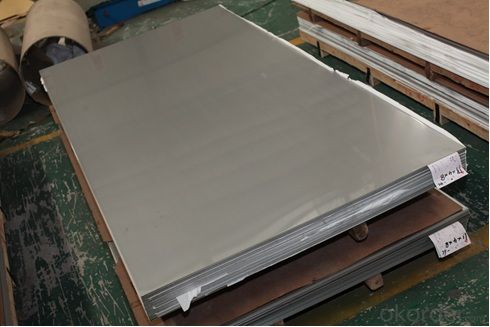

SUS316L No. 1 Finish Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Brief Introduction

SUS316L No. 1 Finish Stainless Steel Plate

---Stainless steel plate applies to construction field, ships building industry, petroleum,

chemical industries, war and electricity industries, food processing and medical industry,

boiler heat exchanger,machinery and hardware fields.

Product Features

. Traditional aesthetics outlook

. Suitable for new house or renovation.

. Less joints, watertight

. Long life service

. Tedun also provide relative ridge cap, fasteners and other accessories

Product Specification

Standard:ASTM, GB,JIS,JIS G3302 ASTM 755 EN10169

Grade: JIS: SUS 201, 202, 301, 304, 304L, 309S, 310S, 321, 316, 316L, 321, 410, 409L, 430

Thickness: 0.13mm~3.0mm,

Width: 10mm-2000mm

Chemical composition:

C | Si | Mn | Cr | Ni | P | S |

0.150 | 0.476 | 11.231 | 12.50 | 0.900 | 0.039 | 0.010

|

FAQ

1. How long will we receive the goods ?

45days after receiving workable L/C

1. how do you control the quality ?

we have our own quality control department ,we will arrange QC person to see the production line ,when goods finish ,before shipment ,our QC person will check the quality as per our test report request ,if the goods is ok ,then we issue the test report ,and we allow the goods shipping ,otherwise will not allow ship the goods.

- Q: What are the advantages of using steel strips?

- There are several advantages of using steel strips. Firstly, steel strips offer exceptional strength and durability, making them suitable for a wide range of applications, from construction to automotive industries. Secondly, steel strips are highly resistant to corrosion and rust, making them a reliable choice for outdoor or humid environments. Additionally, steel strips can be easily formed, bent, or shaped according to specific requirements, providing flexibility in design and customization. Lastly, steel strips have excellent recyclability, making them an environmentally-friendly option that supports sustainable practices.

- Q: Can steel strips be used for making medical devices or implants?

- Yes, steel strips can be used for making medical devices or implants. Steel is a commonly used material in the medical industry due to its high strength, durability, and resistance to corrosion. Steel strips can be shaped, molded, or machined into various medical devices and implants, such as surgical instruments, orthopedic implants, and cardiovascular stents. However, the specific type of steel and its composition must meet the required standards and regulations to ensure biocompatibility and safety for use in medical applications.

- Q: How are steel strips used in the production of solar mounting systems?

- Due to their strength, durability, and versatility, steel strips are an essential ingredient in the manufacturing of solar mounting systems. Throughout the production process, these strips find multiple uses. To begin with, steel strips are commonly employed in constructing the structural frames of solar mounting systems. These frames serve as the base for solar panels, offering stability and support. By shaping and molding the steel strips into the desired frame structure, they ensure the system can withstand the weight of the panels and endure environmental conditions such as wind and snow loads. Additionally, steel strips are utilized in fabricating mounting brackets and rails. These components are responsible for securely attaching the solar panels to the mounting system. By cutting and shaping the steel strips to the required dimensions, they create precise-fit brackets and rails that guarantee a secure attachment for the panels. Moreover, to enhance their corrosion resistance and prolong their lifespan, steel strips are often galvanized or coated with protective layers. This is crucial since solar mounting systems are frequently exposed to various weather conditions, including rain, humidity, and temperature fluctuations. The protective coating on the steel strips ensures that the mounting system can withstand these elements, providing long-lasting support for the solar panels. In conclusion, steel strips have a crucial role in the production of solar mounting systems. They are used to construct the structural frames, mounting brackets, and rails, providing strength, durability, and stability to the entire system. With their versatility and resistance to corrosion, steel strips ensure the longevity and reliability of solar mounting systems in harnessing renewable energy from the sun.

- Q: What is the impact strength of a steel strip?

- The impact strength of a steel strip refers to its ability to withstand sudden, forceful impacts without fracturing or breaking. It is a measure of the strip's resistance to impact or shock loading.

- Q: What is the typical electrical conductivity of steel strips?

- Compared to other metals, steel strips have a relatively low typical electrical conductivity. This is mainly due to the fact that steel primarily consists of iron, which is not a highly conductive material for electricity. The conductivity of steel strips can differ depending on the specific composition and processing methods employed, but it usually falls within the range of 6.99 × 10^6 to 8.43 × 10^6 siemens per meter (S/m). This level of conductivity renders steel strips appropriate for a variety of applications where electrical conductivity is not of utmost importance.

- Q: What is the thickness range of steel strips?

- The thickness range of steel strips can vary depending on the specific application and manufacturing process, but it typically ranges from 0.1mm to 25mm.

- Q: Are steel strips suitable for the manufacturing of food processing equipment?

- Yes, steel strips are suitable for the manufacturing of food processing equipment. Steel is a commonly used material in the food industry due to its excellent strength, durability, and corrosion resistance. Steel strips can be formed and shaped into various components and are easy to clean and sanitize, making them ideal for food processing equipment that requires high hygiene standards.

- Q: What are the different protective coatings available for steel strips?

- There are several different protective coatings available for steel strips, including galvanization, paint, powder coating, and metallic coatings such as zinc or aluminum. These coatings provide a barrier against corrosion, improve the aesthetics, and enhance the durability of the steel strips in various applications.

- Q: How are steel strips used in the manufacturing of electronic components?

- Due to their various properties and advantages, steel strips find common use in the manufacturing of electronic components. These strips are primarily employed for their structural integrity, durability, and conductivity. A primary application of steel strips in electronics manufacturing involves shielding. In order to safeguard electronic components from external electromagnetic interference (EMI) or radio frequency interference (RFI), steel strips are utilized. Their high magnetic permeability and ability to block and absorb unwanted interferences make them excellent for providing such shielding. Manufacturers can ensure the proper functioning and reliability of their products by lining electronic components or enclosures with steel strips. Furthermore, steel strips are also employed in the manufacture of connectors and contacts. These components necessitate materials that possess good electrical conductivity, mechanical strength, and resistance to corrosion. Steel strips, particularly those made of stainless steel, fulfill all of these requirements. They offer excellent electrical conductivity while remaining strong and durable, thus ensuring a reliable connection between different electronic elements. Another utilization of steel strips in electronic manufacturing involves structural support and reinforcement. These strips can be employed as brackets or frames to provide stability to components or circuit boards. They help maintain the structural integrity of electronic devices, particularly in applications where vibration, shock, or high temperatures are present. Steel strips can withstand these harsh conditions and prevent any damage or failure of electronic components. In conclusion, the role played by steel strips in the manufacturing of electronic components is crucial. They are used for shielding against electromagnetic interference, providing conductivity for connectors and contacts, and offering structural support and reinforcement. With their excellent properties such as durability, conductivity, and strength, steel strips contribute to the overall reliability and performance of electronic devices.

- Q: Can steel strips be used in the manufacturing of kitchen appliances?

- Yes, steel strips can be used in the manufacturing of kitchen appliances. Steel is a versatile and durable material that is commonly used in the manufacturing industry. Steel strips can be used to make various components of kitchen appliances, such as the outer casings, internal structures, and even the cooking surfaces. Steel is known for its strength, heat resistance, and corrosion resistance, making it an ideal choice for kitchen appliances that are exposed to high temperatures and moisture. Additionally, steel can be easily molded, shaped, and welded, allowing manufacturers to create complex and precise designs for kitchen appliances. Overall, steel strips are a commonly used material in the manufacturing of kitchen appliances due to their durability, versatility, and ability to withstand the demanding conditions of a kitchen environment.

Send your message to us

SUS316L No. 1 Finish Stainless Steel Plate

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 15 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords