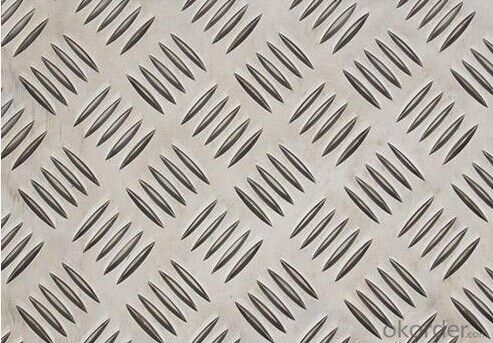

2mm Coated Stucco Embossed Flat Wound Aluminum Coil Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: Can aluminum coils be fabricated or machined?

- Aluminum coils have the ability to undergo fabrication or machining. They are commonly utilized in heating, ventilation, and air conditioning (HVAC) systems, automotive radiators, and electrical transformers. These coils can be tailored and machined according to specific requirements and dimensions. The fabrication of aluminum coils involves procedures such as cutting, bending, and welding in order to achieve the desired shape and size. This allows for customization and adaptation to various applications. Conversely, machining involves the removal of material from the aluminum coil through the use of cutting tools such as lathes, mills, or CNC machines. This process is employed to attain precise dimensions, smooth finishes, and intricate designs. In summary, aluminum coils possess versatility and can be fabricated or machined to accommodate diverse needs. The flexibility of aluminum as a material renders it a favored choice in numerous industries, offering durability, lightweight properties, and exceptional thermal conductivity.

- Q: Are aluminum coils resistant to mold and mildew?

- Generally, aluminum coils have resistance to mold and mildew. Unlike materials like wood or fabric, aluminum is non-porous and does not absorb moisture. This characteristic reduces its susceptibility to mold and mildew growth. Moreover, protective finishes are often applied to aluminum coils, enhancing their resistance to mold and mildew. Nevertheless, it is important to remember that although aluminum coils are less prone to mold and mildew, they are not entirely immune. If exposed to excessive moisture or humidity, mold and mildew can still develop. Thus, regular cleaning and maintenance are essential to prevent potential mold or mildew growth.

- Q: How do aluminum coils contribute to the sound insulation of buildings?

- Aluminum coils contribute to the sound insulation of buildings through their unique properties and applications. Aluminum is a lightweight and flexible material that can be easily formed into coils, making it an ideal choice for sound insulation purposes. One of the main ways aluminum coils contribute to sound insulation is by acting as a barrier to prevent the transmission of sound waves. When installed in walls, ceilings, or floors, these coils create an additional layer that helps to block and absorb sound energy. Aluminum has a high density and rigidity, which allows it to effectively reflect and absorb sound waves, reducing their intensity as they pass through the building structure. Moreover, aluminum coils can be combined with other soundproofing materials, such as foam or fiberglass, to enhance their sound absorption capabilities. These combinations provide a more comprehensive sound insulation system, as the different materials work together to trap and dampen sound waves. Another advantage of aluminum coils is their resistance to moisture and corrosion, which makes them suitable for both indoor and outdoor applications. This durability ensures that the sound insulation provided by aluminum coils remains effective over time, even in harsh environments. Additionally, aluminum coils are easy to install and maintain, making them a cost-effective solution for sound insulation in buildings. Their lightweight nature allows for easy transportation and handling, while their flexibility enables them to be installed in various positions and configurations. In summary, aluminum coils contribute to the sound insulation of buildings by acting as a barrier to sound transmission, reflecting and absorbing sound waves, and providing durability and versatility. Their combination with other soundproofing materials further enhances their effectiveness. With their lightweight and flexible properties, aluminum coils offer a practical and cost-effective solution to improve the acoustic performance of buildings.

- Q: Is it possible to construct a lampshade using an aluminum coil?

- <p>Yes, you can use an aluminum coil to make a lampshade. Aluminum is a lightweight, durable, and heat-resistant material, making it suitable for lampshade construction. You can bend and shape the coil into a desired form and attach it to the lamp base. Ensure proper electrical insulation and avoid direct contact between the coil and the light bulb to prevent overheating. It's advisable to use a professional or follow detailed instructions to ensure safety and a quality result.</p>

- Q: Aluminum alloy coil quotation = = how much is the price?

- 8.3 kilometers, towards the Heze / Dongping /G35 direction, a little right turn, into the Canton Expressway11. along the economy wide highway 280 meters, Ji'nan Yin Jia Lin hub interchange after about 160 meters, go straight into the economy wide highway12., along the Canton Expressway 50.7 kilometers, in Pingyin exports, slightly turn right into the Pingyin interchange13., along the Pingyin interchange 510 meters, 650 meters after crossing Pingyin, straight14. drive 440 meters, turn left ahead into G220 (old)15. along the G220 (old) 1.1 km road, go straight into the Ping Street16. along the Ping Street 3.1 km road, turn left into the road rose17. drive along Rose Road for 510 meters, to the finish line (on the right side of the road)Terminus: Pingyin forever Aluminium Industry Co., Ltd.

- Q: Are aluminum coils suitable for soundproofing applications?

- Typically, soundproofing applications do not involve the use of aluminum coils. Although aluminum is an effective conductor of heat and electricity, it lacks the sound-dampening properties found in other commonly used soundproofing materials like foam, rubber, or dense fibers. These materials are designed to absorb and block sound waves, thereby reducing noise transmission. Conversely, aluminum coils are commonly utilized in HVAC systems or as a building exterior material due to their durability and heat transfer capabilities. Consequently, if the primary goal is soundproofing, it is advisable to explore alternative materials specifically engineered for that purpose.

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. This process involves applying a suitable paint or coating to the surface of the coils to enhance their appearance and provide protection against corrosion or other environmental factors.

- Q: Why there is always impression and indentation on the backup roller of aluminum coil rolling mill with 4 rollers.

- Perhaps there is something wrong in the position controlling the working roller tilt and bend positive and negative convexity, making the working roller out of order and rubbing against the backup roller.

- Q: Can aluminum coils be used in the production of aluminum honeycomb panels?

- Yes, aluminum coils can be used in the production of aluminum honeycomb panels. Aluminum coils are commonly used as the primary material for making aluminum honeycomb panels. The coils are typically processed and shaped into thin sheets or layers, which are then bonded together with an adhesive to form the honeycomb structure. This lightweight and durable structure makes it ideal for various applications, such as aerospace, construction, and transportation industries.

- Q: I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- Plaster releases water at two points - in ordinary or accelerated drying it loses the water needed for setting and stops feeling cool and feels dry. If it is heated past 900F it loses chemically bound water and may fall apart. Aluminum melts at several hundred degrees higher than this and if the mold is intended to hold a mass of aluminum is is likely to destroy the mold. If the aluminum casting is fairly flat less of a problem. The common method for dealing with this is to add 50% silica flour (bad for lungs warning) to the dry plaster when making the mold. Then the mixed material mold can be used and preheated to take materials at least up to fused/molten glass, although the mold is commonly lost (not reusable) at these temps and just barely holds together.

Send your message to us

2mm Coated Stucco Embossed Flat Wound Aluminum Coil Wire

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 700000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords