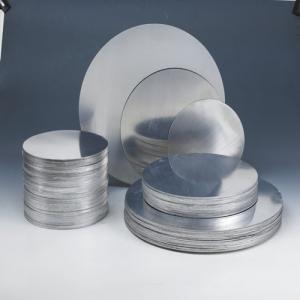

Roll of Aluminum Coil - AA 1070 Diameter 500mm Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

supply Mill-finished / coated aluminum circles /sheet/ coil:

Alloy: AA1050,1060,1100,1200,2024,3003,3304,3005,3015,5052,5086,5754,5083,6061,7050,7475,8011, etc

Temper: O, H14/16/18/22/24/32/ H112/H321/T6,T851,T7451,T7351, etc

Thickness: 0.02mm—20mm

Width: 100mm—2000mm (Can be slitted)

Notice: PE coating / PVDF coating / Embossment can be done if required.

- Q: How are aluminum coils tested for dimensional accuracy?

- Various methods are used to test the dimensional accuracy of aluminum coils to ensure they meet the required specifications. One method commonly employed is the use of specialized equipment like calipers, micrometers, and digital measuring devices. These tools enable precise measurement of the coils' width, thickness, and length. During the testing process, a sample coil is chosen and measured at different points along its length to detect any variations or deviations from the specified dimensions. This helps identify any potential issues with the coil's dimensional accuracy. In addition to manual measurements, advanced technologies such as laser scanning systems and optical sensors are also utilized. These technologies allow for non-contact measurements, resulting in faster and more accurate assessments of the coil's dimensions. Laser scanners create a digital representation of the coil's surface, which can then be compared to the desired specifications to determine the presence of any deviations. Furthermore, computerized systems are employed to analyze the collected data and generate detailed reports. These reports provide comprehensive information about the coil's dimensional accuracy, highlighting any discrepancies from the required standards. This data analysis enables manufacturers to promptly identify and address any potential problems. In conclusion, stringent testing procedures are applied to aluminum coils to ensure their dimensional accuracy. The combination of manual measurements, advanced technologies, and computerized analysis provides a thorough assessment of the coils' dimensions. This enables manufacturers to maintain high-quality standards and deliver products that meet the precise specifications demanded by various industries.

- Q: What is a better deal?Aluminum Cookware ( Paula Deen)orHard Anodized ( Rachael Ray )

- Cook's Illustrated did a study on this and they ended up with the Walmart brand as the best buy because of the inexpensive price and good quality.

- Q: What industries utilize aluminum coils?

- There are several industries that utilize aluminum coils for various purposes. One of the major industries that extensively uses aluminum coils is the construction industry. Aluminum coils are commonly used for roofing, siding, and gutter systems due to their lightweight nature, durability, and resistance to corrosion. Additionally, the transportation industry also relies heavily on aluminum coils for manufacturing automotive parts, such as radiators, condensers, and heat exchangers, as aluminum is known for its excellent heat transfer properties. The packaging industry also utilizes aluminum coils for producing cans and containers due to their ability to preserve the freshness and quality of food and beverages. Moreover, the electrical industry relies on aluminum coils for manufacturing transformers, electrical conductors, and wiring, as aluminum is a good conductor of electricity. Lastly, the aerospace industry uses aluminum coils for constructing aircraft parts, such as wings, fuselage, and structural components, as aluminum provides strength while keeping the weight of the aircraft low.

- Q: Can aluminum coils be painted or printed on?

- Yes, aluminum coils can be painted or printed on. Aluminum is a versatile material that can be coated or painted to achieve various finishes and colors. The surface of aluminum coils can be prepared through a process called pre-treatment, which involves cleaning, etching, and applying a primer. This prepares the surface for painting or printing. Painting aluminum coils involves applying a coating system that typically consists of a primer, a color coat, and a topcoat for protection. The paint can be applied using various methods such as spraying, roll coating, or coil coating. Coil coating, in particular, is a commonly used method where the paint is applied to the coil before it is formed into the desired shape. This ensures a uniform and consistent finish. Printing on aluminum coils is also possible using different techniques such as screen printing, digital printing, or lithography. These methods allow for detailed designs, patterns, or even photographs to be printed onto the surface of the aluminum coil. It is important to note that the choice of paint or printing method may depend on the specific requirements of the application, such as durability, weather resistance, or aesthetic preferences. Additionally, proper surface preparation, selection of suitable coatings, and adherence to recommended application guidelines are essential for ensuring a successful and long-lasting paint or print finish on aluminum coils.

- Q: WHERE IS ALUMINIUM FOUND, LIKE WHERE IS IT MINED FROM...10 points tell me quick

- Bauxite is an aluminium ore and is the main source of aluminium. 95% of the world's bauxite production is processed first into alumina, and then into aluminium by electrolysis.

- Q: Can aluminum coils withstand high temperatures?

- High temperatures are easily withstood by aluminum coils. With a melting point of around 660 degrees Celsius (1220 degrees Fahrenheit), aluminum possesses a relatively high melting point. Consequently, it becomes a suitable choice for applications in high-temperature environments. Moreover, the exceptional thermal conductivity of aluminum facilitates efficient heat dissipation. Due to this characteristic, aluminum coils frequently find application in heat exchangers and diverse heating applications. Nevertheless, it is crucial to acknowledge that the temperature limit for aluminum coils may differ depending on the specific alloy and application.

- Q: Can aluminum coils be used in solar panel systems?

- Yes, aluminum coils can be used in solar panel systems. Aluminum is a commonly used material in solar panel manufacturing due to its lightweight, corrosion resistance, and high thermal conductivity properties. It is often used as a backing material for solar cells and as a component in the frame or structure of the solar panel.

- Q: Can aluminum coils be used in the production of military equipment?

- Indeed, the utilization of aluminum coils in the manufacturing of military equipment is possible. The utilization of aluminum, a lightweight and long-lasting substance, provides numerous benefits for military applications. Its high strength-to-weight ratio renders it a popular choice for constructing military vehicles, aircraft, and naval vessels. Aluminum coils possess the capacity to be molded into diverse shapes and sizes, making them adaptable for fabricating various components such as armor plating, weapon systems, and structural parts. Furthermore, aluminum exhibits commendable resistance to corrosion, a crucial attribute for military equipment operating in harsh environments. In general, aluminum coils are a dependable and extensively employed material in the production of military equipment.

- Q: Are aluminum coils easy to bend and shape?

- Aluminum coils, being a malleable metal, can be easily bent and shaped. This characteristic makes them ideal for various shaping and forming tasks. Different techniques like rolling, bending, or pressing can be employed to manipulate aluminum coils, making them applicable in industries such as construction, automotive, and manufacturing. However, the ease of bending and shaping may vary depending on the specific alloy and thickness of the coil. Thicker coils may necessitate more force and specialized equipment, and different alloys may exhibit varying levels of malleability. In conclusion, aluminum coils present a versatile and relatively uncomplicated material for bending and shaping purposes.

- Q: Is it possible to use an electric stove with an aluminum coil heater?

- <p>Yes, you can use an electric stove with an aluminum coil heater. However, it's important to ensure that the aluminum coil heater is designed for use with an electric stove. Aluminum is a good conductor of heat and can be used in heating elements. Make sure the heater is compatible with the stove's power requirements and that it's installed correctly to avoid any safety hazards. Always follow the manufacturer's instructions for installation and use.</p>

Send your message to us

Roll of Aluminum Coil - AA 1070 Diameter 500mm Aluminium Circles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 800000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords