904L Decorative Stainless Steel Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

ASTM

Technique:

Cold Rolled

Shape:

Square

Surface Treatment:

Polished

Steel Grade:

300 Series

Certification:

BV

Thickness:

1.5

Width:

1500

Length:

3000

Net Weight:

23

stainless steel sheet price 904l

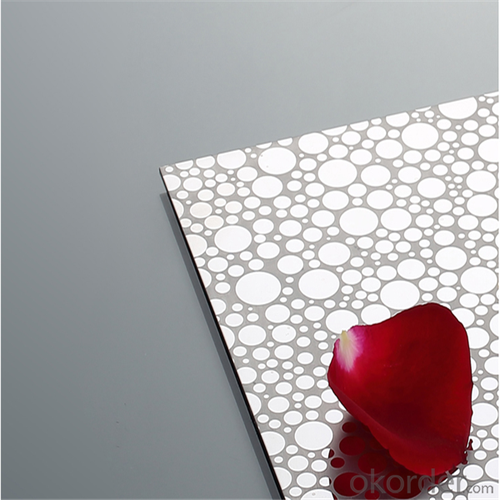

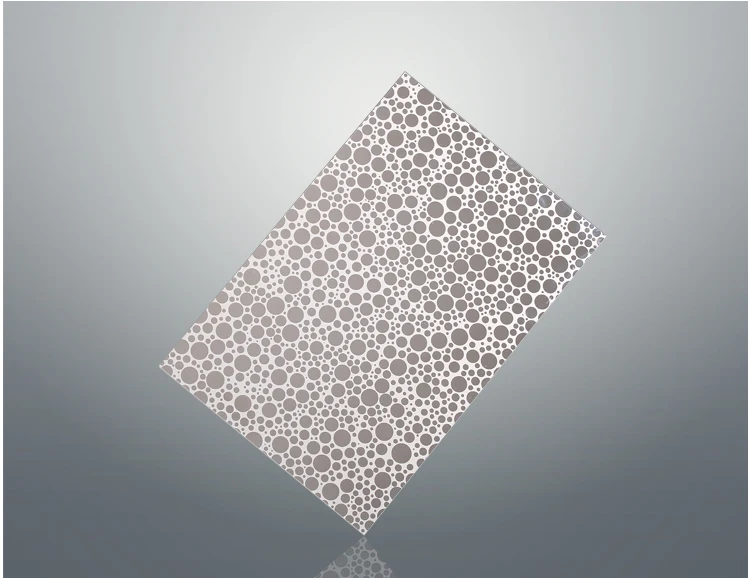

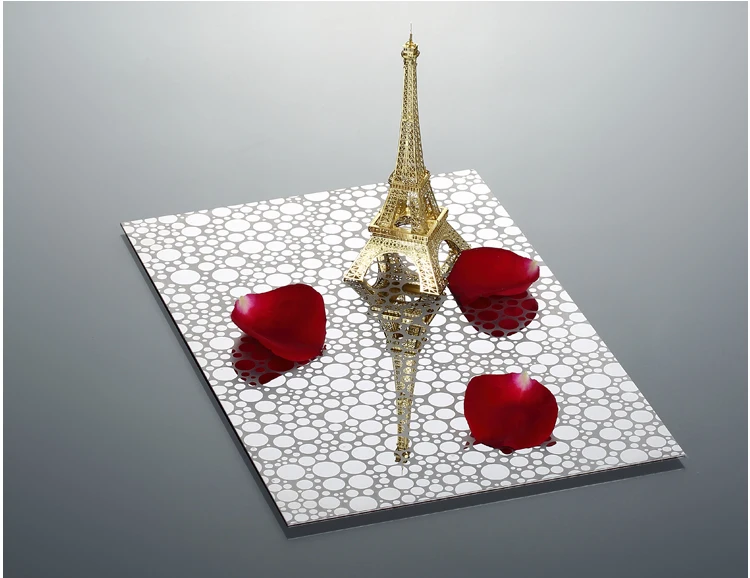

| ype | Decorative stainless steel sheet |

| Name | stainless steel sheet price 904l |

| Thickness | 0.3 mm - 3.0 mm |

| Size | 1000*2000mm, 1219*2438mm, 1219*3048mm, customized Max.width 1500mm |

| SS Grade | 304,316, 201,430 etc. |

| Finish | Mirror +etch+color |

| Avaible finishes | No.4, Hairline, Mirror, Etching, PVD Color, Embossed, Vibration, Sandblast, Combination, lamination etc. |

| Origin | POSCO,JISCO,TISCO,LISCO,BAOSTEEL etc. |

| Packing way | PVC+ waterproof paper + strong sea-worthy wooden package |

| Chemical composition | ||||

| Grade | STS304 | STS 316 | STS430 | STS201 |

| Elong(10%) | Above 40 | 30MIN | Above 22 | 50-60 |

| Hardness | ≤200HV | ≤200HV | Below 200 | HRB100,HV 230 |

| Cr(%) | 18-20 | 16-18 | 16-18 | 16-18 |

| Ni(%) | 8-10 | 10-14 | ≤0.60% | 0.5-1.5 |

| C(%) | ≤0.08 | ≤0.07 | ≤0.12% | ≤0.15 |

- Q: Can stainless steel sheets be used for fireplaces?

- Yes, stainless steel sheets can be used for fireplaces. Stainless steel is a popular material choice for fireplaces due to its high heat resistance and durability. It can withstand the high temperatures generated by the fire without warping or melting, making it a safe and reliable option. Stainless steel sheets can be used to construct the interior of the fireplace, including the firebox and chimney, or can be used as a decorative element on the façade of the fireplace. Additionally, stainless steel is resistant to corrosion and rust, ensuring that the fireplace will maintain its appearance over time.

- Q: What is the price per square foot for stainless steel sheets?

- The price per square foot for stainless steel sheets can vary depending on various factors such as the grade, thickness, finish, and supplier. On average, stainless steel sheets can range from $3 to $10 per square foot. However, high-quality and specialty stainless steel sheets can be priced higher, reaching up to $20 or more per square foot. It is important to consider these factors and shop around to find the best price for your specific requirements.

- Q: Stainless steel plate net price, stainless steel plate net how much one meter?

- Stainless steel punching net is a kind of metal plate net made of stainless steel plate punched by punching machine according to certain pass and mould. Common material: stainless steel punching mesh, divided into several materials, there are 201, 304, 321, 316 and 316L.

- Q: Can stainless steel sheets be used for automotive exhaust systems?

- Indeed, automotive exhaust systems can utilize stainless steel sheets. The use of stainless steel is prevalent in exhaust systems owing to its remarkable resistance to corrosion, ability to withstand high temperatures, and durability. It successfully endures the harsh conditions present in exhaust systems, encompassing intense heat, moisture, and chemicals. Stainless steel sheets can be shaped and manufactured into diverse components of the exhaust system, including pipes, mufflers, and catalytic converters. They offer enduring performance, minimize the likelihood of rust and corrosion, and enhance the overall efficiency and longevity of the automotive exhaust system.

- Q: Which is better, stainless steel plate kitchen?

- Popularly speaking, stainless steel is not easy to rust steel, in fact, part of stainless steel, both rust resistance, but also acid resistance (corrosion resistance). Stainless steel stainless steel and corrosion resistance is on the surface of chromium rich oxide film (film) formation. The rust resistance is relative to that of corrosion resistance. The test shows that the steel in the atmosphere, water and other medium and weak acid oxidizing medium, the corrosion resistance increased with the increase of water content of chromium in steel, when the chromium content reaches a certain percentage, the steel corrosion resistance mutation from rust to rust, corrosion and corrosion resistance to never. There are many classifications of stainless steels.

- Q: How do you restore the shine or finish on stainless steel sheets?

- To restore the shine or finish on stainless steel sheets, there are a few methods you can try: 1. Cleaning with warm water and soap: Start by cleaning the stainless steel sheets with warm water and a mild dish soap. Use a soft cloth or sponge to gently scrub the surface, then rinse with clean water and dry thoroughly with a clean cloth. This should remove any dirt or grime that is dulling the shine. 2. Vinegar solution: If the stainless steel sheets have stubborn stains or dull spots, you can try using a vinegar solution. Mix equal parts white vinegar and water in a spray bottle, then spray the solution onto the surface. Let it sit for a few minutes, then wipe it off with a soft cloth. Vinegar helps to remove stains and restore shine to stainless steel. 3. Baking soda paste: For tougher stains or scratches on stainless steel sheets, you can create a paste using baking soda and water. Mix enough baking soda with water to form a thick paste, then apply it to the stained areas. Gently scrub the surface with a soft cloth or sponge, moving in the direction of the grain. Rinse with water and dry thoroughly. 4. Stainless steel cleaner: There are commercial stainless steel cleaners available that are specifically designed to restore the shine and finish of stainless steel. Follow the instructions on the cleaner and apply it to the surface using a soft cloth or sponge. Rub gently in the direction of the grain and rinse with water. Dry thoroughly to avoid water spots. Remember, always test any cleaning method or solution on a small, inconspicuous area of the stainless steel sheet before applying it to the entire surface. This will help ensure that the method or solution does not cause any damage or discoloration.

- Q: How do you polish stainless steel sheets?

- Achieving a polished look for stainless steel sheets can be accomplished by following a few straightforward steps. Begin by ensuring that the surface is immaculate and devoid of any dirt or debris. To eliminate any stains or marks, a mild detergent or stainless steel cleaner can be used. Next, utilize a soft cloth or sponge to apply either a stainless steel polish or a mixture of vinegar and olive oil. Apply the polish in the direction of the grain, which typically appears as a linear pattern on the stainless steel surface. Once the polish has been applied, utilize another clean cloth to buff the surface in the same direction as the grain. Apply gentle pressure and continue buffing until the stainless steel sheets start to exhibit a shining, polished appearance. If necessary, repeat the process in areas that require further polishing, ensuring that all excess polish is wiped away to prevent streaks or residue. It is crucial to consider that different stainless steel finishes may necessitate specific polishing techniques or products. For optimal results, always consult the manufacturer's instructions or guidelines.

- Q: Can stainless steel sheets be used for electrical or electronic applications?

- Yes, stainless steel sheets can be used for electrical or electronic applications. Stainless steel has excellent electrical conductivity and is resistant to corrosion, making it an ideal material for various electrical components. It is commonly used in electrical enclosures, switchgear, control panels, and other electrical equipment. Additionally, stainless steel sheets can be fabricated into different shapes and sizes, making them suitable for various electronic applications such as printed circuit boards (PCBs), connectors, and terminals. The durability and high temperature resistance of stainless steel also make it a preferred choice for electrical and electronic applications in harsh environments.

- Q: What is the price range for stainless steel sheets?

- The cost of stainless steel sheets can fluctuate based on several factors, including the thickness, size, and grade of the stainless steel. Typically, thinner sheets begin around $30 per square foot, while thicker or higher-grade sheets can reach up to $150 per square foot. It is crucial to consider that market conditions and supplier pricing policies may also impact prices. Thus, it is advisable to compare prices from various suppliers before finalizing a purchase.

- Q: Are stainless steel sheets suitable for cryogenic storage containers?

- Yes, stainless steel sheets are suitable for cryogenic storage containers. Stainless steel is known for its excellent low-temperature properties, making it an ideal choice for cryogenic applications. It has a high resistance to thermal expansion and contraction, making it less prone to cracking or leaking at extremely low temperatures. Additionally, stainless steel is highly durable, corrosion-resistant, and can withstand the extreme conditions of cryogenic storage, ensuring the safety and integrity of the stored materials. Therefore, stainless steel sheets are widely used in the construction of cryogenic storage containers in various industries such as pharmaceuticals, aerospace, and scientific research.

Send your message to us

904L Decorative Stainless Steel Sheet in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords