904l Stainless Steel Sheet Middle East

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

904l Stainless Steel Sheet Middle East

Grade: | 201,304,304L,316,316L,309,309S,310S,904L | Standard: | JIS\AISI\ASTM\GB\DIN\EN\ Other |

Length: | As your request | Thickness: | 0.25mm-3.0mm |

Width: | 15-1500mm | Place of Origin: | Jiangsu, China (Mainland) |

Brand Name: | TISCO | Type: | Coil/sheet |

Application: | Construction\decoration\industry | Certification: | ISO |

Technique: | Cold rolled | Surface: | BA\2B\No.1\No.4\No.8\HL\8K\Brush |

Stock: | Ready in stocks | Package: | According to the requirements |

Edge: | Slit edge & mill edge | Content of Nickel: | 201:1%-1.2%; 304:8% |

Vickers hardness: | HV210 | Thickness tolerance: | ±0.01mm |

Sample: | Available | Material: | Refined raw material |

904l Stainless Steel Sheet Middle East

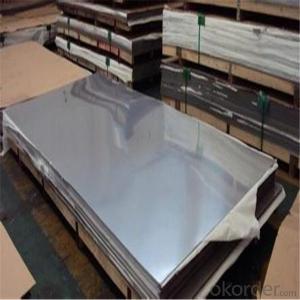

4.Hot rolled stainless steel plate

Thickness : 3.0mm-120mm

Width : 1219mm/1500mm/1800mm/2000mm

Length : 2000mm/2438mm/4000mm/6000mm or cutting randomly

Model size : 3.0mm-120mm(TK)*1219mm(W)*2438mm(L)

3.0mm-120mm(TK )*1500mm(W)*6000mm(L)

3.0mm-120mm(TK) *1800mm(W)*6000mm(L)

3.0mm-120mm(TK) *2000mm(W)*6000mm(L)

Surface : No.1

5.Characteristics and application 904l Stainless Steel Sheet Middle East

Surface Finish | Definition | Application |

NO.1 | The surface finished by heat treatment and pickling or processes corresponding there to after hot rolling. | Chemical industry equipment,Industrial tanks… |

2B | Those finished, after cold rolling, by heat treatment, pickling or other equivalent treatment and lastly by cold rolling to given appropriate luster. | Medical equipment, Food industry, Construction material, Kitchen utensils… |

BA | Those processed with bright heat treatment after cold rolling. | Kitchen utensils, Electric equipment, Building construction… |

NO.4 | Those finished by polishing with No.150 to No.180 abrasives specified in JIS R6001. | Kitchen utensils, Building construction, Medical equipment… |

HL | Those finished polishing so as to give continuous polishing streaks by using abrasive of suitable grain size. | Building Construction… |

8K | A mirror-like reflective surface by polishing with finer abrasives over 800 mesh | Reflector, Mirror, Interior-Exterior decoration |

5.Payment : Usually 30% of the amount by T/T as deposit , and the balance money shall be paid by T/T after got the faxed B/L.Or L/C at sight .

6. Package: Kraft paper+Hard board+metal/wooden pallet+metal strip; or based on the customer requirement.

7. USE: construction.machinebuilding,container manufacturing,shipbuilding,bridges and so on.

The operating philosophy of our company : high quality and best service and competitive price and prompt delivery .We sincerely welcome the old and new customers to inquiry the price . any questions and needs you have , pls don't hesitate to contact us anytime .

- Q: Can stainless steel sheets be used for brewery tanks?

- Yes, stainless steel sheets are commonly used for brewery tanks. Stainless steel is a preferred material in the brewing industry due to its corrosion resistance, durability, and ease of cleaning. It is an ideal choice for tanks that require high sanitary standards and frequently come in contact with acidic or caustic substances.

- Q: What are the benefits of using perforated stainless steel sheets in acoustics?

- Perforated stainless steel sheets in acoustics offer several benefits. Firstly, they can effectively control and manipulate sound waves by allowing sound to pass through the perforations while reducing the intensity of the sound energy. This helps in creating a more balanced and controlled acoustic environment. Secondly, these sheets can be used as sound absorbers, as the holes in the stainless steel sheet absorb and dissipate sound energy, reducing echoes and reverberations. Additionally, perforated stainless steel sheets are durable, corrosion-resistant, and aesthetically pleasing, making them a long-lasting and visually appealing solution for acoustic applications.

- Q: What specifications do stainless steel plates have?

- This is not specified. Do you want to make 201 or 304?. You can measure the size of the bag you want. Double fold (usually 10MM), such as length, width, and thickness of the package. Go and ask someone to do it for you. If fitted, use a glass or spot weld.

- Q: What are the benefits of using brushed stainless steel sheets?

- Using brushed stainless steel sheets has several advantages. To begin with, their sleek and attractive appearance makes them a popular choice for appliances, countertops, and backsplashes. The brushed finish adds a unique texture and matte appearance, bringing sophistication to any space. Additionally, brushed stainless steel sheets are highly durable and resistant to corrosion, making them suitable for indoor and outdoor use. They can withstand harsh conditions such as chemicals, moisture, and extreme temperatures. Moreover, their brushed finish helps to hide fingerprints, smudges, and scratches, making them easy to clean and maintain. Furthermore, brushed stainless steel sheets are hygienic and inhibit bacteria growth, making them ideal for the food and medical industries. Their smooth surface allows for easy cleaning and disinfection, ensuring a safe and sanitary environment. Moreover, these sheets offer excellent longevity and are a cost-effective investment. They resist wear and tear, maintaining their appearance for many years without the need for replacement. Lastly, brushed stainless steel sheets are versatile and can be customized to fit different design preferences. They can be easily cut, shaped, and formed into various sizes and shapes, allowing for endless design possibilities. Whether you prefer a modern, industrial look or a more traditional and elegant style, brushed stainless steel sheets can be tailored to meet your specific needs. In conclusion, the use of brushed stainless steel sheets offers benefits such as an attractive appearance, durability, corrosion resistance, hygienic properties, longevity, and versatility. Whether used in residential, commercial, or industrial settings, these sheets provide a wide range of advantages, making them a popular choice for various applications.

- Q: What's the difference between stainless steel 302 and 304?

- 302 stainless steel and 304 stainless steel are suitable for food processing, storage and transportation. It has good processability and weldability.

- Q: What is the corrosion resistance of stainless steel sheets?

- Stainless steel sheets possess excellent corrosion resistance due to the presence of chromium, which forms a protective oxide layer on the surface, preventing the metal from rusting or corroding in various environments.

- Q: Are stainless steel sheets suitable for elevator doors?

- Yes, stainless steel sheets are suitable for elevator doors. Stainless steel is a durable and corrosion-resistant material that can withstand the wear and tear associated with elevator use. It also offers a sleek and modern appearance, making it a popular choice for elevator doors in various settings.

- Q: How do you prevent pitting or crevice corrosion on stainless steel sheets?

- There are several measures that can be taken to prevent pitting or crevice corrosion on stainless steel sheets: 1. It is crucial to choose the right grade of stainless steel, as grades with higher levels of chromium, molybdenum, and nickel provide better resistance to corrosion. 2. Ensuring a smooth and clean surface is essential. Corrosion can be initiated by rough surfaces or scratches. Creating a smoother surface can be achieved by polishing or electropolishing the stainless steel sheets. 3. Regular cleaning using mild detergents and non-abrasive cleaners is important to remove contaminants that may corrode the stainless steel sheets. It is also necessary to avoid using chlorine-based cleaners or abrasive materials that can damage the protective oxide layer. 4. Pitting and crevice corrosion are intensified in stagnant environments, so proper drainage and avoiding the accumulation of stagnant water or debris can help prevent this type of corrosion. 5. Stainless steel sheets should be protected from exposure to aggressive chemicals, such as chloride-containing solutions or acidic substances. Additionally, proper ventilation and humidity control can help reduce the risk of corrosion. 6. Applying protective coatings, such as paints or passivation treatments, can provide an additional layer of protection against pitting and crevice corrosion. 7. Regular inspections should be conducted to detect any signs of corrosion early on. Prompt remedial actions, such as repairing damaged coatings or addressing any drainage issues, can prevent the spread of corrosion. By following these preventive measures, the risk of pitting or crevice corrosion on stainless steel sheets can be significantly reduced, ensuring their longevity and maintaining their aesthetic appeal.

- Q: What are the different grades of stainless steel sheets?

- Stainless steel sheets are available in various grades, each offering different properties and characteristics. The most commonly used grades of stainless steel sheets include: 1. 304 Stainless Steel: This is the most widely used grade and is known for its excellent corrosion resistance, good formability, and high strength. It is commonly used in food processing equipment, kitchen appliances, and chemical containers. 2. 316 Stainless Steel: This grade has even better corrosion resistance than 304 stainless steel and is often used in marine environments or applications involving exposure to corrosive chemicals. It also has good welding and forming properties. 3. 430 Stainless Steel: This is a ferritic grade that is commonly used in applications requiring good corrosion resistance and moderate strength. It is often used in automotive trim, kitchen equipment, and decorative applications. 4. 410 Stainless Steel: This grade is a martensitic stainless steel that offers high strength and hardness. It is commonly used in applications where wear resistance and corrosion resistance are required, such as cutlery, surgical instruments, and industrial equipment. 5. 201 Stainless Steel: This is a low-nickel grade that offers good formability and moderate corrosion resistance. It is commonly used in decorative applications, such as architectural trim, appliances, and furniture. These are just a few examples of the different grades of stainless steel sheets available. The choice of grade depends on the specific application and the desired properties of the material, such as corrosion resistance, strength, formability, and cost.

- Q: How do you prevent crevice corrosion on stainless steel sheets?

- To prevent crevice corrosion on stainless steel sheets, it is important to ensure proper cleaning and maintenance. Regularly inspect the sheets for any signs of damage or corrosion and promptly address any issues. Avoid leaving stagnant water or debris in crevices or gaps as they can promote corrosion. Applying protective coatings, such as paints or sealants, can also help prevent crevice corrosion. Additionally, using stainless steel grades that are more resistant to crevice corrosion, such as 316 or 317, can be beneficial in preventing this type of corrosion.

Send your message to us

904l Stainless Steel Sheet Middle East

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords