8oz Non Woven Geotextile for Fiberglass Geogrid Reinforcement and Separation in Dam and River

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

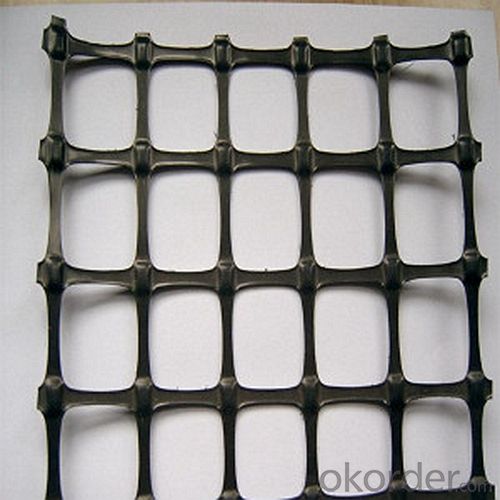

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size

can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

ITEM

50KNX50KN/M

100KNX100KN/M

MESH SIZE

25.4X25.4MM

25.4X25.4MM

TENSILE STRENGTH

WARP 50KN/M

WARP 100KN/M

WEFT 50KN/M

WEFT 100KN/M

WEIGHT

300G/SQM

500G/SQM

ELONGATION AT BREAK

3%

3%

TENSILE STRENGTH IN KNOT

5KN/M

10KN/M

WIDTH:

1--6M

1--6M

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q: How do geotextiles help in groundwater drainage?

- Geotextiles help in groundwater drainage by allowing water to pass through while preventing soil particles from clogging the drainage system. They act as a filter, providing a barrier against soil erosion and maintaining the permeability of the drainage system, thus improving the overall efficiency of groundwater drainage.

- Q: What are the different geotextile filter criteria?

- The different geotextile filter criteria include permeability, retention, durability, and compatibility. Permeability refers to the ability of the geotextile to allow water to pass through while retaining soil particles. Retention is the capability of the geotextile to prevent soil particles from passing through, ensuring effective filtration. Durability assesses the geotextile's resistance to physical and chemical degradation over time. Compatibility refers to the geotextile's compatibility with the soil and other materials it is in contact with, ensuring long-term effectiveness.

- Q: Can geotextiles be used in coastal protection?

- Yes, geotextiles can be used in coastal protection. Geotextiles, which are permeable fabrics made of synthetic fibers, can be utilized for erosion control, shoreline stabilization, and sediment filtration in coastal areas. They can help prevent soil erosion and provide stability to slopes and embankments. Additionally, geotextiles can be used in the construction of groynes, breakwaters, and revetments, providing protection against wave action and reducing the impact of coastal erosion.

- Q: Welding of impervious geotextile

- 1. Seam processing is the key to the construction process, the general use of heat welding method, PE film surface heat treatment, so that the surface melting, and then through the pressure, so that one fusion. 2. For the laying of a good geomembrane, edge seams require no oil, water, dust and so on. 3. Before welding to adjust the seam at the two sides of the PE single film, so that a certain width of the lap, lap width is generally 6 ~ 8 cm and smooth, no wrinkles. 4. Use special welding machine for welding. Welding construction effect map:

- Q: Sponge city sunken green land in the drilling drainage jacket how to set the amount of geotextile

- Need plastic blind ditch, complete specifications, collar Xiang new materials for your answer

- Q: What are the different methods of installing geotextiles?

- There are several methods of installing geotextiles, including trench installation, direct placement, and mechanical installation. Trench installation involves excavating a trench and placing the geotextile in the trench before backfilling. Direct placement involves laying the geotextile directly on the ground surface and securing it with stakes or other means. Mechanical installation utilizes specialized equipment, such as a geotextile installation machine, to roll out and secure the geotextile in place.

- Q: Are geotextiles commonly used in riverbank protection applications?

- Yes, geotextiles are commonly used in riverbank protection applications. They are often employed to stabilize soil, prevent erosion, and enhance water filtration in riverbank protection projects.

- Q: How do geotextiles improve the performance of geogrids?

- Geotextiles improve the performance of geogrids by acting as a separator, preventing the mixing of different soil layers and allowing for better load distribution. They also provide filtration, allowing water to pass through while preventing the migration of fine particles, which helps in maintaining the stability and longevity of the geogrid. Additionally, geotextiles act as a cushioning layer, reducing the potential for damage to the geogrid and enhancing its overall effectiveness in reinforcement applications.

- Q: What are the factors to consider when designing geotextile-reinforced slopes?

- When designing geotextile-reinforced slopes, several factors need to be considered. These include the type and strength of geotextile to be used, the slope angle and height, soil properties, expected loads and stresses, water drainage and erosion control measures, construction methods, and long-term performance requirements. Additionally, site-specific conditions such as climate, vegetation, and nearby structures should also be taken into account. Proper consideration of these factors ensures a safe and stable design that effectively mitigates slope failures and erosion.

Send your message to us

8oz Non Woven Geotextile for Fiberglass Geogrid Reinforcement and Separation in Dam and River

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords