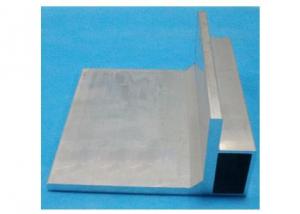

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles compatible with glass?

- Glass is compatible with aluminum profiles. In different applications like windows, doors, curtain walls, and partitions, aluminum frames are often used as framing systems for glass panels. This compatibility is due to aluminum's lightweight, durability, and resistance to corrosion, which make it an excellent material for holding and supporting glass panels. By using different profile designs, aluminum frames can securely hold glass of various types and thicknesses, giving structural stability and enhancing the overall appearance. Furthermore, aluminum profiles can be customized and engineered to meet specific glass installation needs, ensuring a perfect fit and compatibility between the two materials.

- Q: What are the specifications of aluminium alloy door and window profiles?

- The main specifications of aluminum alloy doors and windows are: 35 series, 38 series, 40 series, 60 series, 70 series, 90 series, etc.. The so-called 35, 38...... Refers to the aluminum alloy profiles, the main frame width of 35 mm, 38 mm, respectively....... Sealed balcony usually adopts 70 series or 90 series, and if less than 70, the degree of firmness is difficult to guarantee.

- Q: Acrylic coating principle, coating on the aluminum section, he and fluorocarbon powder spraying, what is the difference

- Compared with the other two spraying methods, the best quality, the most beautiful appearance, but the price is expensive, not green. Used in high-end buildings, commercial building more

- Q: What are the noise reduction properties of aluminum profiles?

- Due to their inherent characteristics, aluminum profiles exhibit outstanding noise reduction properties. The effective material for reducing noise transmission is aluminum, thanks to its high density and rigidity. When utilized in structural applications, aluminum profiles have the ability to dampen and absorb sound waves, thereby limiting their propagation and decreasing noise levels. The incorporation of additional noise-reducing features is made possible by the versatility of aluminum profiles. To further enhance their noise reduction properties, aluminum profiles can be combined with insulating materials such as foam or rubber. This combination creates a barrier that absorbs sound waves, preventing their passage and minimizing noise transmission. Furthermore, the reduction of noise is aided by the ability of aluminum profiles to be designed with intricate shapes and structures. By employing innovative designs like ribbing or perforations, the profiles can effectively scatter and disrupt sound waves, resulting in reduced noise levels. Additionally, the noise reduction capabilities of aluminum profiles can be enhanced by anodizing or coating the surfaces with sound-absorbing materials. These surface treatments contribute to the absorption and dissipation of sound energy, leading to a reduction in noise resonance and an improvement in overall acoustic performance. In conclusion, due to their density, rigidity, and versatility, aluminum profiles possess excellent noise reduction properties. When combined with insulating materials, innovative designs, and surface treatments, aluminum profiles are capable of effectively reducing noise transmission, making them a suitable choice for applications where noise control is of utmost importance.

- Q: Are aluminum profiles suitable for mass production or large-scale projects?

- Yes, aluminum profiles are highly suitable for mass production and large-scale projects. Aluminum is a lightweight and versatile material that offers excellent strength and durability. Its malleability allows for easy customization and fabrication, making it ideal for creating complex shapes and designs. Additionally, aluminum profiles have excellent corrosion resistance, ensuring longevity in various environmental conditions. Moreover, aluminum is recyclable, making it a sustainable choice for large-scale projects. Therefore, aluminum profiles are a preferred choice for industries such as construction, automotive, aerospace, and manufacturing, where mass production and large-scale projects are common.

- Q: Can aluminum profiles be subjected to painting or coating processes to improve their aesthetic appeal and resistance to wear?

- <p>Yes, aluminum profiles can be painted or coated. This process not only enhances their appearance but also significantly improves their durability and resistance to corrosion. Aluminum has a natural oxide layer that provides some protection, but painting or coating can offer additional layers of defense against environmental factors. These coatings can be applied through various methods such as powder coating, anodizing, or electrophoretic deposition, each providing a different finish and level of protection. The choice of coating depends on the specific requirements for appearance, performance, and the environment in which the aluminum profile will be used.</p>

- Q: How are aluminum profiles insulated?

- There are several methods available to enhance the thermal performance of aluminum profiles. One way is to incorporate a thermal break into the profile design. This involves inserting a non-conductive material, such as polyamide or polyurethane, between the inner and outer parts of the profile. By doing so, heat transfer between the interior and exterior of a building is minimized, resulting in improved energy efficiency. Another approach to insulating aluminum profiles is to apply insulating materials, such as foam or rubber, to either the interior or exterior surfaces of the profile. These materials act as barriers, reducing heat transfer and providing additional insulation. Additionally, insulating gaskets or seals can be fitted to aluminum profiles. These gaskets, typically made of rubber or other insulating materials, are positioned between the profile and the glazing. They create a thermal barrier, preventing heat loss or gain. In summary, the insulation of aluminum profiles can be achieved through the incorporation of thermal breaks, the application of insulating materials, or the use of gaskets. These methods effectively minimize heat transfer and enhance the energy efficiency of buildings.

- Q: This question asks about the various applications of aluminum profiles within the construction industry.

- <p>Aluminum profiles are versatile in construction and have several uses: 1. Structural framing for buildings, providing support and stability. 2. Window and door frames, known for their durability and resistance to corrosion. 3. Facade systems, offering lightweight and aesthetically pleasing exterior solutions. 4. Modular construction, where aluminum profiles can be prefabricated and assembled quickly. 5. Roofing and cladding systems, due to their weather resistance and ease of installation. 6. Handrails and balustrades for safety and design. 7. Solar panel mounting structures, taking advantage of aluminum's lightweight and strength. 8. Scaffolding systems, for temporary construction support. These applications highlight aluminum's adaptability and strength in construction.</p>

- Q: What are the different shapes available for aluminum profile cross-sections?

- There are several different shapes available for aluminum profile cross-sections, depending on the specific application and requirements. Some common shapes include: 1. Square: This shape features equal sides and right angles, making it suitable for applications where stability and strength are important, such as structural framing. 2. Rectangular: Similar to square profiles, rectangular profiles have unequal sides and can be used in a wide range of applications, including enclosures, frames, and supports. 3. T-shaped: This shape consists of a central vertical section with a horizontal section extending from one side, resembling the letter "T." T-shaped profiles are often used for joining two components or for providing additional support to structures. 4. L-shaped: L-shaped profiles have a 90-degree angle and are commonly utilized as brackets, corner reinforcements, or frame components. 5. Round: Round aluminum profiles have a circular cross-section and are frequently employed in applications where a smooth, curved appearance is desired, such as handrails, furniture, or decorative elements. 6. I-beam: Resembling the letter "I," these profiles have a central vertical section (known as the web) and two horizontal sections (known as the flanges). I-beams are widely used in construction and structural engineering due to their high strength-to-weight ratio. 7. U-channel: U-channel profiles have a U-shaped cross-section and are often used as edge protectors, trim, or guides. They can also be utilized as tracks for sliding doors or as reinforcement beams. 8. Hexagonal: Hexagonal profiles have six sides and can be used in applications where increased strength and rigidity are required, such as machinery frames or support structures. These are just a few examples of the different shapes available for aluminum profile cross-sections. It is important to choose the most appropriate shape based on the specific requirements of the intended application to ensure optimal performance and functionality.

- Q: What are the noise insulation properties of aluminum profiles?

- Aluminum profiles have good noise insulation properties due to their density and ability to dampen sound vibrations. They can effectively reduce external noise and provide a quieter indoor environment.

Send your message to us

80/20 Anodized Alu Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords