6063 Alloy H22 Aluminum Rolled Sheet Aluminium Coil - Aluminum Coil Slitting Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

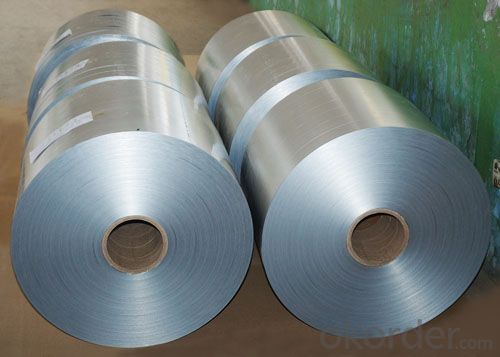

6063 Alloy H22 Aluminum Rolled Sheet Aluminium Coil

aluminum coil specifications:

1) Alloy :1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc

2) Temper: O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc

3) Thickness: 0.1mm to 6mm

4) Width:20mm to 3300mm

5)Coil weight: 100kgs to 6 tons depends on actual requirement

6)Core material: Aluminum or paper

7)Coil Inner diameter: 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required

8) Protective film can be added

item | 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: What are the different alloy grades used in aluminum coils?

- Aluminum coils employ various alloy grades, each possessing distinct properties and applications. Among the commonly used grades are the following: 1. 1100: Commercially pure aluminum grade renowned for its remarkable corrosion resistance and high thermal conductivity. Frequently utilized in applications necessitating good formability, like fin stock, heat exchangers, and chemical equipment. 2. 3003: This alloy grade boasts moderate strength and excellent workability. It finds extensive use in applications requiring both corrosion resistance and formability, such as packaging, cooking utensils, and general sheet metal work. 3. 5052: Offering a compelling combination of strength, formability, and corrosion resistance, this alloy grade is often employed in marine environments and transportation equipment like fuel tanks and vehicle bodies. 4. 6061: A heat-treatable alloy grade recognized for its outstanding strength and weldability. Commonly utilized in structural applications like bridges, aircraft parts, and bicycle frames. 5. 7075: Another heat-treatable alloy grade renowned for its high strength-to-weight ratio. Frequently employed in aerospace applications and the fabrication of high-stress components, including firearm parts and rock climbing equipment. These examples merely represent a fraction of the various alloy grades employed in aluminum coils. The choice of the appropriate grade hinges on the specific requirements of the application, encompassing desired strength, corrosion resistance, formability, and thermal conductivity.

- Q: What is the corrosion resistance of aluminum coils in saltwater environments?

- Aluminum coils have excellent corrosion resistance in saltwater environments due to the formation of a protective oxide layer on their surface. This oxide layer acts as a barrier, preventing direct contact between the aluminum and the corrosive saltwater, thereby reducing the risk of corrosion.

- Q: Can aluminum coils be used for electrical conductors?

- Indeed, aluminum coils are capable of serving as electrical conductors. Aluminum, being a metal with exceptional conductivity, finds frequent utilization in electrical contexts. With electrical conductivity ranking second only to copper, aluminum proves to be a fitting material for the conduction of electricity. In numerous electrical apparatuses and setups like transformers, motors, generators, and power transmission lines, aluminum coils are commonly employed.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: What are the disadvantages of using aluminum coils?

- There are several disadvantages of using aluminum coils in various applications. Firstly, aluminum coils tend to have a lower heat transfer coefficient compared to other materials like copper. This means that they may not be as efficient in transferring heat, which can negatively impact the performance and energy efficiency of cooling or heating systems. Additionally, aluminum coils are more prone to corrosion compared to copper coils. This is especially true in environments with high humidity or exposure to harsh chemicals. Corrosion can lead to leaks in the coil, reducing its lifespan and potentially causing damage to the system. Another disadvantage of aluminum coils is their relatively lower tensile strength compared to other materials. This means that they may be more susceptible to damage or failure under excessive pressure or stress. This can be a concern in applications where the coils are subject to high pressure or frequent movement. Furthermore, aluminum coils can be more expensive compared to other materials like copper. While aluminum itself is a cheaper material, the manufacturing processes involved in producing aluminum coils and the additional coatings required to improve its performance can increase the overall cost. Lastly, aluminum coils may require more maintenance and cleaning compared to other materials. Due to their tendency to accumulate dust, dirt, and debris more easily, regular cleaning is necessary to maintain their performance and prevent clogging or blockages. Overall, while aluminum coils have their advantages such as being lightweight and resistant to corrosion in certain environments, it is important to consider these disadvantages when choosing the appropriate coil material for specific applications.

- Q: What are the recognized standards that dictate the quality of aluminum coil?

- <p>Yes, there are several standards that define the quality of aluminum coil. These include ASTM B209, which specifies requirements for aluminum and aluminum alloy flat sheet, coil, and plate for general usage. ASTM B210 covers aluminum and aluminum alloy sheet and plate for heat-treating. Additionally, EN 485 is a European standard that specifies the requirements for aluminum and aluminum alloy cold-rolled sheets, strips, and plates. These standards outline dimensions, chemical composition, mechanical properties, and other quality aspects to ensure the material meets industry requirements.</p>

- Q: Can aluminum coils be painted or coated for aesthetic purposes?

- Yes, aluminum coils can be painted or coated for aesthetic purposes. Aluminum is a versatile material that can be easily painted or coated to enhance its appearance. Painting or coating aluminum coils can provide a wide range of color options and finishes, allowing for customization and aesthetic appeal in various applications. The paint or coating can also provide additional protection against corrosion and weathering, increasing the durability and longevity of the aluminum coils. However, it is important to select the appropriate type of paint or coating that is compatible with aluminum and suitable for the intended use to ensure optimal results.

- Q: Is it possible to utilize aluminum coil as a conductor for speaker wires?

- <p>While it is technically possible to use aluminum coil as speaker wire, it is not recommended. Aluminum has higher resistance and lower conductivity compared to copper, which is the standard material for speaker wires. This can result in signal loss and reduced sound quality. Copper is preferred due to its superior electrical conductivity, ensuring minimal signal degradation over distance. For optimal audio performance, it's best to use speaker wire made from high-quality copper or copper-clad aluminum.</p>

- Q: Can aluminum coils be anodized for enhanced durability?

- Yes, aluminum coils can be anodized to enhance their durability. The anodizing process creates an oxide layer on the surface of the aluminum, making it more resistant to corrosion, wear, and abrasion. This improves the overall lifespan and performance of the coils.

- Q: When they say to coat entire roof system with Aluminum coating, what does that mean? The area to coat is NOT the ceramic barrel tiles of a roof but the flat section covered with tar paper and granules of shiny sand. Is it a liquid? Clear? Good for the roof.? How is it applied?

- Why you would be coating a flat roof with Aluminum coating is beyond anything I have learned. Flat roofs should have a felt and tar coating to water proof them. Aluminum roof coating is used mostly on mobile homes to reflect heat because mobile homes don't have attics to trap the heat and carry it to vents. It also seals the water out at the metal seams. Aluminum coating is a type of polymer that has aluminum flakes in it. It is brushed on like a thick coat of paint and allowed to dry.

Send your message to us

6063 Alloy H22 Aluminum Rolled Sheet Aluminium Coil - Aluminum Coil Slitting Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords