5005 Aluminum Coil with PE Coating for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

Our Quality for PE coated aluminum coils with alloy 3003 is very good, especially in corrosion resistance, weather resistance and high strength.

Embossed aluminum sheets have many advantages. Embossing can not only increase thickness of aluminum, but also enhance strength and rigidity of aluminum coils. Embossed & coated aluminum coils look more beautiful and widely used in decorations.

2. Main Features of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

• Light Weight

• Good in strength and rigidity

• High Flatness

• Good Weathering

• Colorful

• Recycling

• Saving Energy

• Rust proof

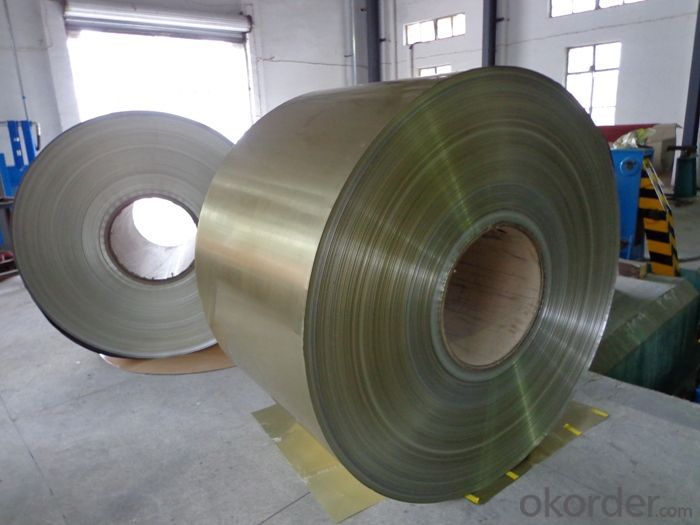

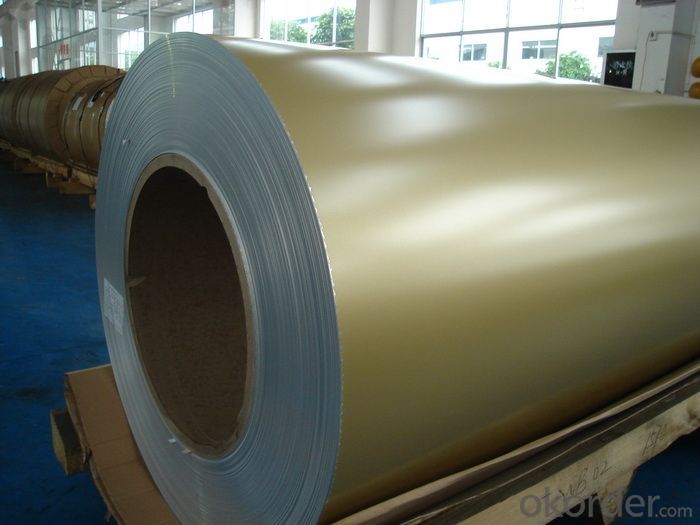

3. 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels Images

4. Specification of 3003 Aluminium Coils with PE Coating Used for Aluminum Composite Panels

ALLOY | TEMPER | THICKNESS | WIDTH | COATING and COLOR |

3003, 3105, etc | H44, etc | 0.2-0.6mm | Less than1600mm | AS PER YOUR REQUIREMENTS |

5. FAQ

A.What about inspections to guarantee quality?

For each order, we will arrange strict inspection for raw materials, inspection during production and inspection for finished goods.

With requirement of customers, we also can arrange the third party inspection.

B.What about delivery?

We will put order in production schedule after order gets confirmed against copy of TT or L/C. Normally it takes about one month for production. Exact shipment schedule is different based on different sizes and quantity.

C.What is the MOQ?

5 tons for each size.

D. Where have you exported?

We have exported to many countries. Main markets include South East Asia, Middle East, North America, South America, etc.

- Q: What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q: How are aluminum coils used in the production of HVAC ductwork?

- Aluminum coils play a significant role in the production of HVAC ductwork. These coils are made from high-quality aluminum material that is lightweight, durable, and corrosion-resistant, making them ideal for use in HVAC systems. The first step in utilizing aluminum coils for HVAC ductwork production is the manufacturing process. The coils are initially rolled into thin sheets, which are then cut into specific widths and lengths to match the size requirements of the ductwork. This flexibility in sizing allows for customized ductwork that fits perfectly in various HVAC systems. Once the aluminum coils are cut into the desired dimensions, they are then formed into the shape of the ductwork. This can be done through a variety of methods, such as bending, folding, or rolling, depending on the design and specifications of the ductwork. One of the key advantages of using aluminum coils in HVAC ductwork production is their excellent thermal conductivity. Aluminum is a highly effective heat conductor, which means that it can efficiently transfer heat or cold air throughout the HVAC system. This property is essential for the proper functioning of the ductwork, as it helps maintain the desired temperature in different areas of a building. Moreover, aluminum coils are known for their resistance to corrosion, which is crucial in HVAC systems. The coils are exposed to various elements, including moisture, which can lead to rust and deterioration in other materials. Aluminum, on the other hand, naturally forms a protective oxide layer that prevents corrosion, ensuring the longevity and reliability of the HVAC ductwork. Furthermore, the lightweight nature of aluminum coils makes them easy to handle and install. This reduces the labor and time required for ductwork installation, resulting in cost savings for both manufacturers and installation teams. Additionally, the lightweight nature of aluminum coils reduces the overall weight of the HVAC system, making it more energy-efficient and reducing the strain on other components. In conclusion, aluminum coils are an essential component in the production of HVAC ductwork. Their lightweight, durable, and corrosion-resistant properties, along with excellent thermal conductivity, make them ideal for efficiently transferring air throughout the HVAC system. Additionally, the flexibility in sizing and ease of installation further contribute to their widespread use in the HVAC industry.

- Q: like we have seen a disk of aluminum spinning, and a permanent magnet repell the plate because apparently because of temporary hystersis and because the north or south field causes the same in the aluminum, so why wont a plate of ruby do the same thing? Are not all metals, crystals? Perhaps its just too big and difficult a question for you simple huumans,..eh?

- Hey, magnets work on iron and steel, but not on non-ferrous metals.

- Q: Can aluminum coils be used in automotive suspension systems?

- Yes, aluminum coils can be used in automotive suspension systems. Aluminum coils are lightweight, durable, and have excellent corrosion resistance, making them suitable for use in suspension systems. They provide better handling, improved ride quality, and enhance fuel efficiency in vehicles.

- Q: Can aluminum coils be customized according to specific requirements?

- Indeed, aluminum coils possess the capability to be personalized in accordance with particular demands. To accommodate diverse applications, aluminum coils can undergo customization to suit distinct dimensions, thicknesses, and finishes. The range of customization options encompasses specific alloys, tempering processes, and even specialized coatings, which serve to enhance corrosion resistance or augment appearance. Furthermore, aluminum coils can be fabricated with specific attributes such as perforations, embossing, or edge treatments, tailored to fulfill precise functional or aesthetic prerequisites. The inherent ability of aluminum coils to be customized bestows upon them a quality of flexibility and versatility, rendering them invaluable across a multitude of industries and applications.

- Q: Can aluminum coils be used in the production of aluminum composite roofs?

- Aluminum composite roofs can indeed utilize aluminum coils. Due to their durability, lightweight composition, and corrosion resistance, aluminum coils are frequently employed in the manufacturing process of aluminum composite roofs. These coils can be effortlessly molded and arranged into the desired roof profile, resulting in a smooth and visually pleasing final product. Furthermore, aluminum possesses exceptional thermal and sound insulation qualities, rendering it an optimal selection for roofing purposes. Its remarkable strength-to-weight ratio additionally bolsters the overall structural stability of the roof. In summary, the utilization of aluminum coils in the production of aluminum composite roofs furnishes a dependable and enduring roofing solution.

- Q: How is Aluminum formed??Thanks!!

- okorder nice.

- Q: So on friday we mixed crystaline copper chloride stuffs with water to make a clear blue solution. We then put some aluminum into the solution. The solution began to heat up and there was a redish brown precipitate at the end. What caused the heat? What was boiling? How does the mass of the original aluminum and original copper chloride crystaline stuff compare with the mass of the red/brown power stuff (we strained the liquid out), and the mass of the dried up blue stuff?

- You're looking at a redox reaction. During this process, the copper ions in solution are reduced to form copper metal (visible as dust) and the aluminum metal is oxidized to form aluminum ions. This process is exothermic due to the relative electron affinities and the positions on the activity sequence such that copper has a greater affinity for electrons and is a stronger oxidizing agent. I think aluminum forms a 3+ ion and copper forms either a 1+ or a 2+ ion. Copper's molecular weight is 63g/mol and aluminums weight is 27 g/mol. You would see the weight decrease because aluminum weighs less than Copper and is replaced less frequently due to the higher charge when you figure out the ionics. Nothing was boiling.

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing aluminum coils in food storage.

- <p>Advantages of using aluminum coils for storing food include their excellent heat conductivity, which allows for even heating and cooling, making them ideal for temperature-sensitive food items. They are also lightweight, durable, and resistant to corrosion, which enhances their longevity. Additionally, aluminum coils are recyclable, contributing to environmental sustainability. Disadvantages include potential health concerns due to the leaching of aluminum into food, especially in acidic environments. There's also the risk of denting or scratching the surface, which can compromise the integrity of the coil and lead to contamination. Moreover, aluminum coils may not be suitable for all types of food storage, particularly those requiring airtight or vacuum sealing.</p>

- Q: I have completely disassembled my aluminum bass boat and it is being sandblasted.I am restoring the boat and will be giving it a new paint job.What do you recommend in the way of primer,paint or anything else I need to know.I just don,t want to mess it up by using the wrong thing.Best answer gets a fishing trip in the same boat we are talking about. If you can make it here I will put you on some fish.Catfish,bream,crappie,bass or even saltwater fish.

- Altough Pettit says you can topcoat this primer, you will probably get a better result if you prime the primer with whatever is recommended for the type of topcoat you use. For the hull, use a paint with a high UV rating, and avoid using red, it oxidizes faster. I would also suggest you use the Alumaprotect inside the hull as well.

Send your message to us

5005 Aluminum Coil with PE Coating for Aluminum Composite Panels

- Loading Port:

- Yantai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 7 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords