4x8 Sheets of Diamond Plate Aluminum - High Quality 1100 3003 5083 6061 7075 Metal Alloy Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Packaging & Delivery

Packaging Details: | Standard export packing or following customer's demand |

Delivery Detail: | Within 20-25days or according to the order quantity |

High Quality and Factory Price Aluminum Coil

Specifications

Grade

| 1000 Series: 1050 1060 1070 1100 1200 1235 etc. 3000 Series: 3003 3004 3005 3104 3105 3A21 etc. 5000 Series: 5005 5052 5083 5086 5154 5182 5251 5754 etc. 6000 Series: 6061 6063 6082 6A02 etc. 8000 Series: 8006 8011 8079 etc. |

Thickness | 0.05~10mm |

Width | <1600mm< span=""> |

Color | Metallic, Solid, RAL or by customer requirements |

Coating paint: | PVDF(Polyvinylidene Fluoride), PE(Polyester ) |

Coating thickness | as per customer’s request |

Gloss | 10-90%(EN ISO-2813:1994) |

Total coating thick | Polyester18~27micron(EN ISO-2360:1995) PVDF27 ~35micron(EN ISO-2360:1995) |

Coating hardness | 2H |

Protective film | PVC film, Colorless transparent or White-black |

Adhesion | 5B (EN ISO-2409:1994) |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) |

Flexibility (T-bend) | 0T- 2T |

Temper | H16, H18, H24, H26, H26 |

Certification | ISO9001:2000, CE, SGS |

Coil's standard diameter | 1100mm |

Inner Diameter | 405mm/505mm |

Coil's standard weight | 2000kgs |

Payment | L/C ,T/T |

Parameter

Product | Alloy | Temper | Thickness | Width | I.D(mm) | Application |

Aluminum Coil/Strip | 1050,1060,1070, 1100,1200,1235, 1145,3003,304, 3105,3A21, 8011 | O H12 H14 H16 H18 H22 H24 H26 | 0.2-8mm | 50-2400mm | 75,150 200,300 400,505 (as customers's request) | construction,decoration, automobile,electronic, machinery,boat construction, aeronatics&astronautics, cookware,packing etc. |

Application:

1) Radiator

2) Condenser

3) Insulation Material

4) Construction

5) Decoration

6) Advertisement and market applications

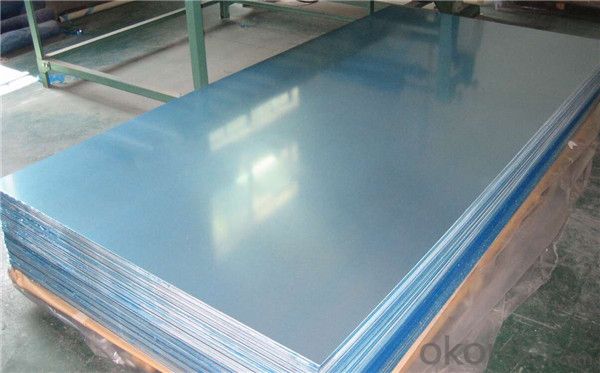

Photos

- Q: Do 101 aluminum sheets have any specific insulation properties?

- No, 101 aluminum sheets do not have any specific insulation properties. Aluminum is a good conductor of heat and electricity, which means it does not provide insulation against heat or cold. However, aluminum sheets can be used as a reflective surface to reflect heat or light. To provide insulation, additional materials such as foam or fiberglass can be added along with the aluminum sheets.

- Q: What is the bending radius for aluminum sheets?

- The bending radius of aluminum sheets may vary depending on the sheet's thickness and alloy. In general, thinner sheets (around 1-3 mm) should have a bending radius of approximately 1.5 times their thickness. On the other hand, thicker sheets (over 3 mm) can increase the bending radius to around 2.5 times their thickness. Nevertheless, it's important to bear in mind that these are general guidelines and the bending radius may need to be adjusted according to the specific application and desired outcome. To obtain accurate bending radius information, it is always recommended to seek advice from a professional or consult the manufacturer's technical data sheets.

- Q: Aluminum plate thickness 1 cm, iron plate thickness 0.15 cm, area 1 square meters, thank you

- It's too difficult. Just think about it

- Q: What are the advantages of using aluminum sheets in the transportation industry?

- There are several advantages of using aluminum sheets in the transportation industry. Firstly, aluminum sheets are lightweight, which helps to reduce the overall weight of vehicles, resulting in improved fuel efficiency and reduced carbon emissions. Secondly, aluminum sheets offer excellent corrosion resistance, ensuring durability and longevity, even in harsh environments. Additionally, aluminum is highly malleable and can be easily formed into various shapes, enabling design flexibility and customization. Moreover, aluminum sheets have high strength-to-weight ratio, providing structural integrity and safety. Finally, aluminum is a recyclable material, making it a sustainable choice for the transportation industry.

- Q: What is the composition of 101 aluminum sheets?

- The composition of 101 aluminum sheets typically consists of 99.5% pure aluminum with trace amounts of other elements such as iron and silicon.

- Q: What is the electrical conductivity of aluminum sheets?

- The electrical conductivity of aluminum sheets is quite high, as aluminum is known to be an excellent conductor of electricity.

- Q: How to mix solid aluminium sheet with solid copper sheet (using heat?) to make a compound.

- I'm not sure if I correctly understand your question - that is, whether you're asking how to physically fasten copper and aluminum pieces together, or of you're asking how to make intermetallic compounds of copper and aluminum. Since you did mention a compound, though, I'm guessing the latter. Copper and aluminum do react to form a number of intermetallic compounds. Among these are Al4Cu9, AlCu, and Al2Cu (see first reference below). These are referred to as aluminides of copper, and may be prepared by melting the two metals together in the proper ratio by weight and cooling slowly. For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 96% aluminum and 4% copper (see second reference below). Note that a protective inert atmosphere is desirable for any work of this sort to prevent oxidation. CORRECTION: The compound CuAl2 contains about 54% copper and 46% aluminum (NOT as above). It's the 2000 series aluminum alloys which contain around 4% copper, and it is the precipitation of CuAl2 during heat treatment which makes them hardenable. The final sentence in the second paragraph above should read: For example, Al2Cu (also called CuAl2) may be prepared by melting a mixture containing 46% aluminum and 54% copper (see second reference below).

- Q: What are the potential safety issues that may arise from the use of aluminum sheets?

- <p>Aluminum sheets are generally safe to use in most applications. However, there are a few safety concerns to consider. First, aluminum can be a skin irritant for some individuals, so it's important to wear protective gloves when handling. Second, aluminum dust, when inhaled, can cause respiratory issues. Proper ventilation should be maintained during cutting or grinding operations. Lastly, aluminum can conduct electricity, so it should not be used in electrical applications without proper insulation. Always follow safety guidelines and use protective equipment when working with aluminum sheets to minimize these risks.</p>

- Q: Is it possible to utilize aluminum sheets in the construction of environmentally friendly buildings?

- <p>Yes, aluminum sheets can be used for green building materials. They are lightweight, durable, and have high recyclability, which reduces waste. Aluminum is also energy-efficient in production and use, and its reflective properties can help in reducing heat absorption, thus lowering cooling costs. Additionally, aluminum's resistance to corrosion and weathering means it requires less maintenance, contributing to its sustainability in green building practices.</p>

- Q: 1) Aluminum ore is not formed in Quebec (why not?) 2)but aluminum ore is smelted into aluminum in Quebec. Why?

- The okorder

Send your message to us

4x8 Sheets of Diamond Plate Aluminum - High Quality 1100 3003 5083 6061 7075 Metal Alloy Made in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords