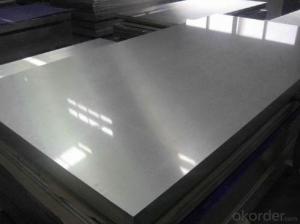

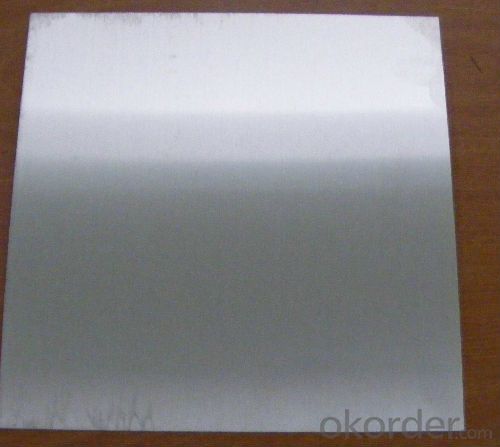

4x10 Sheets of Aluminum Siding - GB Standard Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We can provide all kinds of aluminum sheet,the specification as below:

Description | Alloy | Temper | Sizemm | Norms & | ||

Thickness | Width | Length | ||||

Non-heat- | 1xxx, 3xxx, | O,F,H111,H112,H12, | 0.2~1.0 | 500~1500 | 900~1700 | YS/T91 |

1.1~2.0 | 800~1800 | 500~10000 | ||||

5xxx series | O,F,H111,H112,H12, | 0.2~1.0 | 800~1500 | 2000~10000 | GB/T3880 | |

Heat-treatable | 2xxx, 6xxx, | O,F,H111,H112, | 0.5~1.0 | 800~1500 | 2000~10000 | YGB/T3880 |

T351,T451, | 5.0~150 | 800~2500 | 2000~10000 | GJB1741 | ||

Braze welding | LQ1, LQ2, | O,H24 | 0.5~4.0 | 800~1800 | 2000~10000 | YS/T69 |

Tread plate | 1x,3x,5x | O,H22,H24,H26 | Bottom thick | 800~1600 | 2000~10000 | GB/T3618 |

Curtain wall sheet | 1x,3x series & 5005,5052 | O,H14,H24 | 1.5~4.0 | 914~2200 | 1500~5500 | YS/T429.1 |

Packaging & Delivery

| Packaging Details: | In wooden cases or based on your requirement |

| Delivery Detail: | 15--30 days after we receive deposit |

Question 1: Who are we?

Answer: Are we just Aluminum Sheet manufacturer and seller?

NO! CERTEG is not only selling Aluminum Sheet, but also produce aluminum coil,aluminum foil,aluminum circle,color coated aluminum coil and checkered aluminum sheet

Question 2: How do we provide better service?

Answer:

♥ We focus on every detail of our products, including raw material quality control, production,

package, loading, shipment and the final installation.

♥ SAY NO TO FLAW!

2.1 Manufacture

We have 8 production lines with 10000MT capacity per Month.

2.2 Quality Control

Quality test

Tips: The third party inspection is also acceptable (SGS, BV, COC, etc.)

2.3 Packing & Loading

Wooden Pallet ,Wooden Case or as customer's request.

Question 3: How is the quality?

Answer:

The quality is good.We control the quality from material to whole processing.And we have professional QC team to make sure the quality.Only the good quality goods will be delivered.

- Q: This question asks for methods to prevent aluminum sheets from warping or curling during processing or storage.

- <p>To prevent aluminum sheets from warping or curling, ensure proper storage by keeping them flat and avoiding stacking them under heavy loads. Maintain a controlled environment with consistent temperature and humidity to prevent expansion and contraction. When cutting, use sharp tools to minimize heat generation and stress. Apply a stress-relieving process after fabrication to reduce internal stresses. Use appropriate jigs and fixtures during fabrication to maintain flatness. Finally, consider the thickness and alloy of the aluminum sheet, as some are more prone to warping than others.</p>

- Q: Are the aluminum sheets suitable for manufacturing electronic enclosures?

- Indeed, aluminum sheets are well-suited for the production of electronic enclosures. The reason for aluminum's popularity in this regard lies in its remarkable combination of strength, durability, and lightness. Moreover, its capacity for conducting electricity effectively qualifies it for dissipating the heat generated by electronic components. Furthermore, aluminum sheets can be effortlessly molded, shaped, and machined to meet the precise specifications of electronic enclosures, thereby allowing for personalized and adaptable designs. Additionally, its ability to resist corrosion renders it suitable for safeguarding electronic devices against environmental elements. In summary, aluminum sheets offer the perfect material solution for the manufacturing of electronic enclosures.

- Q: What are the environmental benefits of using aluminum sheets?

- There are several environmental benefits of using aluminum sheets. Firstly, aluminum is a highly recyclable material, meaning that it can be reused repeatedly without losing its quality. This reduces the need for mining and extraction of new aluminum, conserving natural resources and minimizing the environmental impact of the production process. Additionally, aluminum has a lower carbon footprint compared to other metals, as it requires less energy to produce. Moreover, aluminum is lightweight, which reduces fuel consumption during transportation, leading to lower greenhouse gas emissions. Overall, using aluminum sheets helps in promoting a more sustainable and eco-friendly approach to manufacturing and construction.

- Q: Is aluminum sheet resistant to UV rays?

- Yes, aluminum sheet is resistant to UV rays. Aluminum naturally forms a protective oxide layer that acts as a barrier against UV radiation. This oxide layer helps to prevent the aluminum sheet from being damaged or degraded by exposure to the sun's UV rays. This makes aluminum sheet a suitable material for outdoor applications, where it can withstand prolonged exposure to sunlight without fading or deteriorating. Additionally, the reflective properties of aluminum further contribute to its UV resistance, as it can reflect a significant amount of the sun's rays, reducing heat absorption and potential damage.

- Q: Can aluminum sheets be recycled indefinitely?

- Yes, aluminum sheets can be recycled indefinitely.

- Q: what's the size of gap while pressing 6mm aluminum sheet?

- unilaterial gap is 0.1-0.15mm, and you can change the gap according to cutting effect.

- Q: What kind of aluminum sheet is most suitable for constructing the exterior walls of a building?

- <p>The best type of aluminum sheet for building exterior walls is typically aluminum composite material (ACM) or aluminum coil coated with a protective layer. ACM is lightweight, durable, and offers excellent resistance to weather and corrosion. It also provides good thermal insulation and is easy to install. Coated aluminum coils are often used for cladding due to their strength, low maintenance, and longevity. The choice may also depend on specific project requirements, such as aesthetic considerations, budget, and local climate conditions.</p>

- Q: This question asks whether it is possible to utilize stamped or embossed aluminum sheets for a specific project.

- <p>Yes, you can use stamped or embossed aluminum sheets in your project. These sheets are known for their strength, durability, and lightweight properties, making them ideal for various applications such as construction, automotive, and aerospace. Stamped aluminum sheets are formed by pressing the material into a specific shape, while embossed sheets have a raised pattern. Both types offer design flexibility and can be customized to meet specific project requirements. Ensure that the aluminum sheets you select meet the necessary specifications for your project, such as thickness, strength, and finish.</p>

- Q: Is it feasible to recycle aluminum sheets and what factors contribute to its recyclability?

- <p>Yes, aluminum sheets can be recycled easily. Aluminum is one of the most recycled materials due to its lightweight, durability, and the energy efficiency of the recycling process. The recycling of aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. Additionally, aluminum can be recycled indefinitely without losing its properties, making it an environmentally friendly choice. Proper sorting and collection systems are crucial for efficient recycling, and the demand for recycled aluminum is high in various industries, further facilitating its recycling process.</p>

- Q: What are the different methods of surface cleaning for aluminum sheet?

- Different methods exist for cleaning aluminum sheets, each with unique advantages and suitability for various situations. Common methods include: 1. Mechanical Cleaning: Scrubbing the aluminum sheet with abrasive materials like sandpaper or wire brushes can physically eliminate dirt, oxidation, or other contaminants. Although effective for removing severe stains or corrosion, this method may cause scratches. 2. Chemical Cleaning: Utilizing cleaning agents or solvents, chemical cleaning dissolves and eliminates dirt, grease, or oxidation from the aluminum sheet. Depending on requirements, the cleaning agents can be acidic, alkaline, or neutral. This method is ideal for removing light stains or surface oxidation and is suitable for large-scale cleaning operations. 3. Electrolytic Cleaning: By immersing the aluminum sheet in an electrolyte solution and applying a direct current, electrolytic cleaning uses electricity to dissolve and separate contaminants from the surface. This method is effective for eliminating heavy oxidation, corrosion, or stubborn stains. 4. Ultrasonic Cleaning: Placing the aluminum sheet in a tank filled with a cleaning solution and subjecting it to high-frequency sound waves, ultrasonic cleaning creates tiny bubbles that dislodge dirt particles upon contact with the sheet's surface. It is suitable for removing fine particles, oils, or grease. 5. Steam Cleaning: High-pressure steam is employed in steam cleaning to remove dirt, grime, or contaminants from the aluminum sheet's surface. The steam's high temperature and pressure break down dirt particles and sanitize the sheet. This method effectively removes oils, greases, or organic residues. When selecting a cleaning method for aluminum sheets, factors such as the type and severity of contamination, desired cleanliness level, and specific application requirements must be considered. Additionally, it is crucial to follow safety guidelines and use appropriate protective equipment when handling cleaning agents or working with electrical equipment.

Send your message to us

4x10 Sheets of Aluminum Siding - GB Standard Mill Finished Aluminum Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m²

- Supply Capability:

- 9000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords