430 Stainless Steel Plate ss400 hardness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

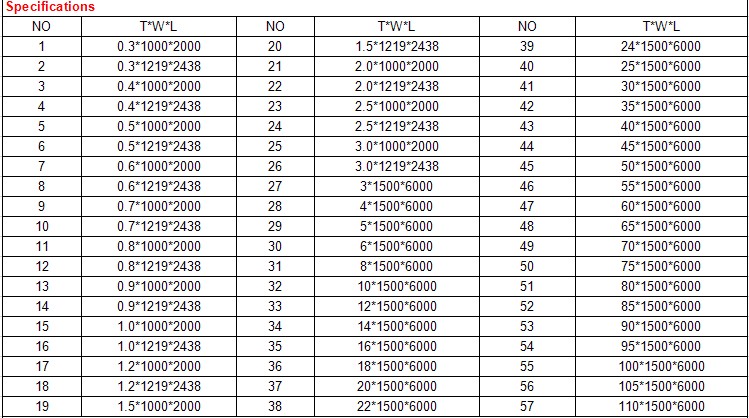

Specification

| Product Details |

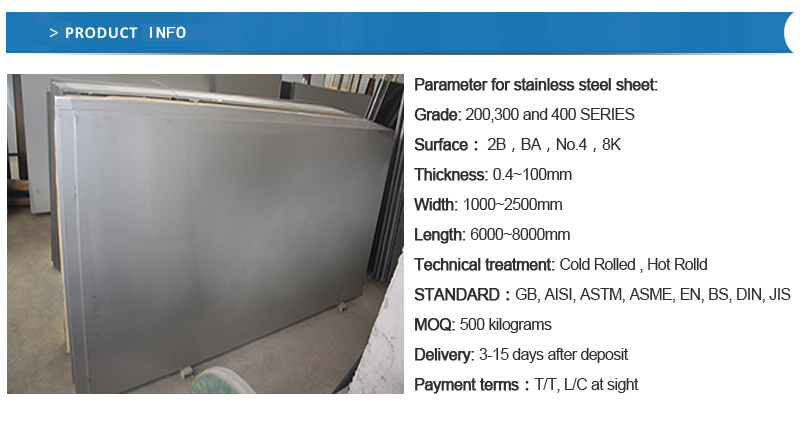

| Product name | Stainless steel sheet |

| Brand name | RONSCO |

| Standard | ASTM A240, ASTM A480, EN10088, JIS G4305 |

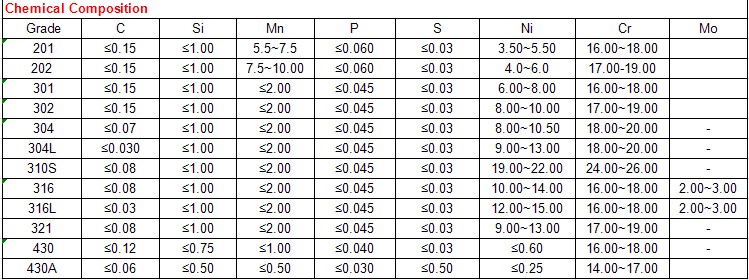

| Material | 304, 316L, 321, 310S, 1.4301, 1.4307, 1.4404, S31803, S32750, 904L, Monel 400, Inconel 800 |

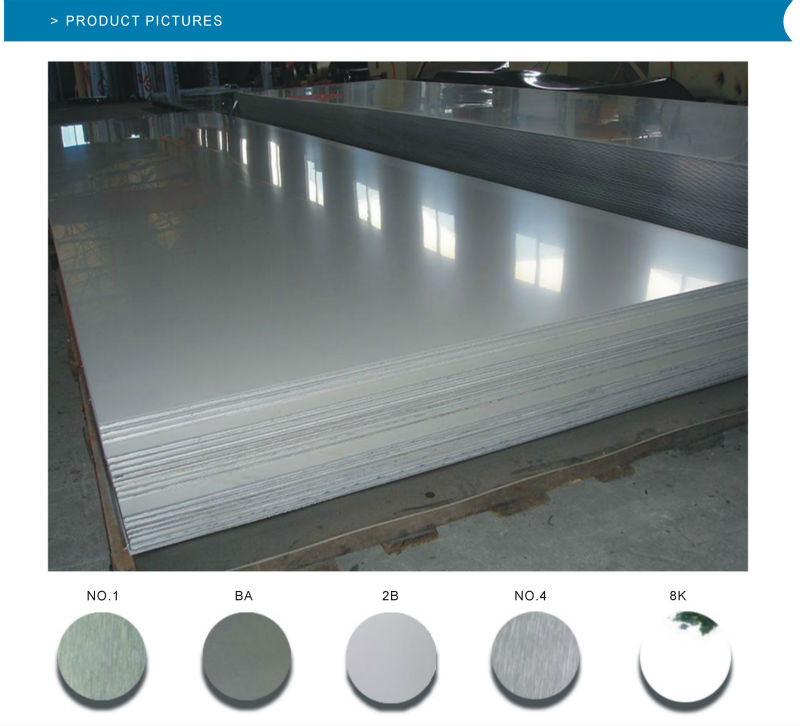

| Surface | NO.1,2B,NO.4,BA,SB,Satin,Brushed,Hairline,Mirror |

| Payment | T/T,L/C at sight |

| Packing | In wooden cases,in wooden pallets |

| Shipment | By sea, by air, by express |

Click here to get more information

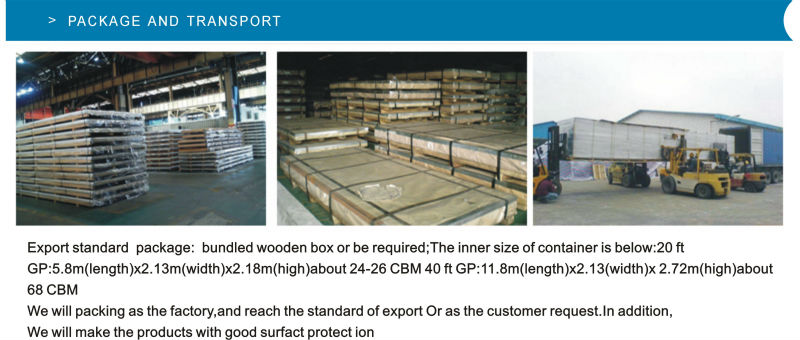

Packaging & Shipping

Packaging is one of the best service of Ronsco, in order to prevent the damage from transit, our finished products are packaged carefully. All of our stainless steel sheet products will be transported with steel pallets or wooden pallets.

Customers will be guaranteed that the product they received from Ronsco can go directly into the production and out to the customers as finished product.

- Q: Stainless steel without fingerprint processing how to get?

- Anti fingerprint (also known as non fingerprint) stainless steel plate is a protective layer treatment process is extremely thin and solid formed on the surface of stainless steel by nano coating technology, the stainless steel surface can not only achieve the anti fingerprint effect, also can improve the anti corrosion resistance;

- Q: Can stainless steel sheets be used for mezzanine flooring?

- Yes, stainless steel sheets can be used for mezzanine flooring. Stainless steel is a durable and corrosion-resistant material, making it suitable for high traffic areas like mezzanine floors. It offers strength and stability, making it a popular choice for industrial and commercial applications.

- Q: How do you remove scratches from stainless steel sheets?

- There are a few techniques you can try to eliminate scratches from stainless steel sheets. To begin, you can opt for a non-abrasive cleaner or a mild detergent mixed with warm water. Apply this solution to the scratched area using a soft cloth or sponge, and gently rub in circular motions. Thoroughly rinse the area and dry it with a clean cloth. If the scratches still persist, you can experiment with a stainless steel scratch removal kit. These kits often provide a polishing compound specially formulated for stainless steel. Apply the compound to the scratched area and use a soft cloth to polish the surface along the grain. Continue polishing until the scratches vanish. For deeper scratches, you might need to employ fine-grit sandpaper or a stainless steel scratch repair pen. Begin by lightly sanding the scratched area, following the grain. Be cautious not to exert excessive pressure, as this can harm the surface. After sanding, meticulously clean the area and use a polishing compound to restore the shine. It is important to acknowledge that these methods may not entirely eliminate deep scratches, and there may be cases where professional repair is necessary. Furthermore, always test any cleaning or repair method on a small, inconspicuous area before applying it to the entire surface to avoid causing further damage.

- Q: Can stainless steel sheets be used in automotive industry?

- Yes, stainless steel sheets can be used in the automotive industry. Stainless steel is a popular material choice in the automotive industry due to its various advantageous properties. It offers excellent resistance to corrosion, making it suitable for parts that are exposed to harsh weather conditions, such as car exteriors and body panels. Stainless steel sheets are also known for their high strength-to-weight ratio, which allows for the design and production of lightweight yet durable automotive components. Additionally, stainless steel is highly resistant to heat and can withstand high temperatures, making it suitable for applications such as exhaust systems. Overall, stainless steel sheets are widely used in the automotive industry for their durability, corrosion resistance, and versatility in various applications.

- Q: How do you bend stainless steel sheets?

- To effectively bend stainless steel sheets, a combination of skill, knowledge, and the right tools is necessary. Follow these steps for successful bending: 1. Identify the specific grade of stainless steel you are working with as each grade possesses unique characteristics affecting malleability and bending response. 2. Prior to bending, ensure the stainless steel sheet is clean and devoid of any dirt or debris. Use a mild detergent and a soft cloth for surface cleaning. 3. Mark the precise bending line by measuring and indicating the desired spot. Utilize a ruler or straight edge for accuracy. 4. Select an appropriate bending tool based on the size and thickness of the stainless steel sheet. Options include a press brake, rolling machine, or bending machine. 5. Gradually apply pressure by placing the stainless steel sheet in the bending tool, aligning it with the marked bending line. Avoid excessive force to prevent cracking or deformation. 6. Adjust the bending angle as needed by repositioning the stainless steel sheet within the bending tool. Utilize the tool's adjustments or supplementary tools like clamps for precise angles. 7. Inspect the result by carefully removing the stainless steel sheet from the bending tool. Check for defects, cracks, or unevenness. Minor adjustments can be made using a rubber mallet or a hammer with a soft face. Keep in mind that bending stainless steel sheets requires practice and precision. Begin with smaller projects and gradually advance to more complex bends. If uncertain or lacking experience, consult a professional in metal fabrication for the best outcomes.

- Q: How do stainless steel sheets resist corrosion?

- Stainless steel sheets resist corrosion due to their unique composition and protective oxide layer. Stainless steel is made up of iron, chromium, and other alloying elements such as nickel and molybdenum. The presence of chromium in stainless steel is crucial for its corrosion resistance. When exposed to oxygen, chromium forms a thin and invisible oxide layer on the surface of the stainless steel, known as the passive layer. This passive layer acts as a barrier that prevents oxygen and moisture from reaching the underlying metal, thus protecting it from corrosion. It is this layer that gives stainless steel its name, as it remains "stainless" or free from rust and corrosion. The chromium oxide layer is self-repairing and can reform if damaged or scratched, ensuring the continued protection of the stainless steel. This property allows stainless steel sheets to be used in various environments, including those with high humidity, exposure to chemicals, and even saltwater. Additionally, the alloying elements like nickel and molybdenum enhance the corrosion resistance of stainless steel. Nickel increases the stability and strength of the passive layer, while molybdenum improves resistance to pitting and crevice corrosion. Furthermore, stainless steel sheets can be further protected against corrosion through surface finishes, such as polishing or passivation. These processes remove any contaminants or impurities from the surface and promote the formation of a more robust and uniform passive layer. Overall, the combination of chromium, other alloying elements, and the protective oxide layer make stainless steel sheets highly resistant to corrosion, providing durability and longevity in various applications.

- Q: Can stainless steel sheets be used for elevator door frames?

- Yes, stainless steel sheets can be used for elevator door frames. Stainless steel is a durable and corrosion-resistant material, making it suitable for such applications where strength and aesthetics are important.

- Q: Are stainless steel sheets good for exhaust systems?

- Yes, stainless steel sheets are highly suitable for exhaust systems due to their exceptional heat resistance, durability, and corrosion resistance properties. Additionally, stainless steel sheets offer high strength and are able to withstand extreme temperatures and harsh environments, making them an ideal choice for exhaust systems that are exposed to heat, moisture, and chemicals.

- Q: Can stainless steel sheets be used for solar panel frames?

- Solar panel frames can indeed be made from stainless steel sheets. The use of stainless steel is quite popular for solar panel frames because of its exceptional strength, durability, and resistance to corrosion. It can endure various weather conditions, such as extreme heat, humidity, and exposure to sunlight. In addition, stainless steel is both non-magnetic and non-combustible, ensuring the safety of solar panel installations. Moreover, its high strength-to-weight ratio permits lighter frame designs, reducing the overall weight of the solar panels and facilitating their installation. All in all, stainless steel sheets are a dependable and enduring choice for constructing solar panel frames.

- Q: Are stainless steel sheets suitable for architectural designs?

- Yes, stainless steel sheets are suitable for architectural designs. Stainless steel is a versatile material that offers a wide range of benefits for architectural projects. Its durability and resistance to corrosion make it ideal for both indoor and outdoor applications. Additionally, stainless steel sheets can be easily fabricated into various shapes and sizes, allowing architects to create unique and visually appealing designs. The sleek and modern appearance of stainless steel adds an aesthetic appeal to buildings, making it a popular choice in contemporary architecture. Furthermore, stainless steel is a sustainable material as it is 100% recyclable, making it an environmentally friendly choice for architectural designs. Overall, stainless steel sheets offer numerous advantages that make them highly suitable for architectural designs.

Send your message to us

430 Stainless Steel Plate ss400 hardness

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords