304 Stainless Steel Metal Sheet CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 35000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

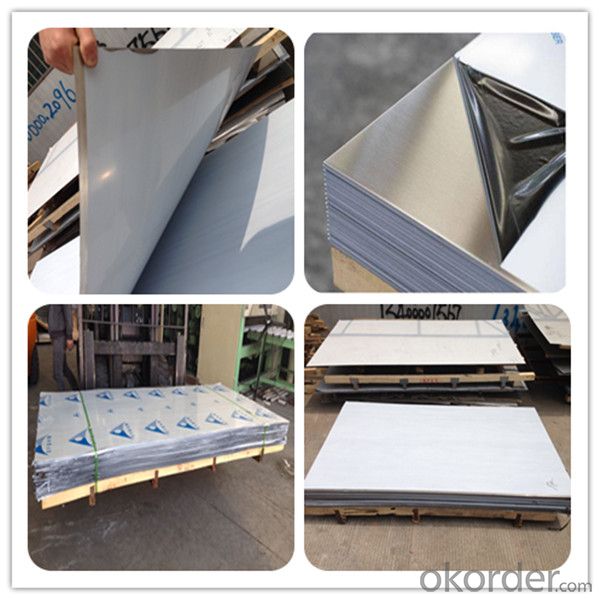

Good quality304 stainless steel metal sheet CNBM

1.Product Description

1. Specifications about stainless steel sheet price sus304

Commodity430 304 304L 316L 201 316 4x8 sheet metal prices stainless steel

Grade201,202,304,304L,316,316L,310S,309S,321,301,310,410,420,430,904L

BrandTISCO ,BAOSTEEL,POSCO,JISCO,LISCO

CertificationSGS,BV,IQI,TUV,ISO,etc

Thickness0.2mm-150mm

Width1000,1219,1250,1500mm, or as your requirements

Length2000,2438,2500,3000,6000mm, or as your requirements

SurfaceNo.1, 2B, BA, 8K Mirror, Hairline,satin, Embossed,brush,No.4,HL,matt,pvc film,laser film.

StandardASTM,AISI,SUS,JIS,EN,DIN,GB, ASME,etc

Delivery time5-7 days after confirming the order

MOQ1 Ton

AdvantagesShowing the splendor of your quality, wearresistant as well , strong corrosion resistance and decorative effect, durable and beautiful in good taste.

2.Products photos

FAQ

Q1. Are you a manufacturer or trader?

We are one of largest trade platform in China, which total turnover volume of CNBM exceeds US$32 billion dollars with a total staff of 11000 and listed in the world top 500 enterprise with good reputation and abundant capital.

Q2.How can you assure your quality and delivery time?

First, our material all from some big mill brands and we get EU CE certification.I will show it to you if you need.

Second,our quality guarantee period is about 3 years within this period, if non-human causes, we will be given a free replacement.

Third,we have complete quality control system and have a lot of mill inspectors all the factory in our country.

Forth,We can provide you certificate of quality accordingly. You know,we only choose the first class manufacturer for cooperation.

Last,We are willing to accept the third party inspection,such as SGS,BV,CE and so on.No doubt,we need to cooperate with you completely.

- Q: How do you prevent warping or distortion in stainless steel sheets?

- To prevent warping or distortion in stainless steel sheets, several measures can be taken. First, it is important to properly handle and store the sheets to prevent any bending or twisting during transportation or storage. Secondly, ensuring a smooth and even distribution of heat during welding or fabrication processes can help minimize the chances of warping. Additionally, using proper clamping techniques and supports during machining or cutting operations can help maintain the shape and integrity of the stainless steel sheets. Lastly, adhering to the recommended thicknesses and specifications provided by the manufacturer for specific applications can also help prevent warping or distortion in stainless steel sheets.

- Q: Are stainless steel sheets fire-resistant?

- Yes, stainless steel sheets are fire-resistant. Stainless steel is a heat-resistant material that can withstand high temperatures without losing its structural integrity. This makes it an ideal choice for applications that require fire resistance, such as in the construction industry, where stainless steel sheets are commonly used for fireproofing walls, roofs, and enclosures. Additionally, stainless steel has a high melting point, which means it can withstand extreme heat without deformation or melting, further enhancing its fire-resistant properties.

- Q: How do stainless steel sheets compare to other types of sheet metals?

- Stainless steel sheets offer several advantages over other types of sheet metals, making them a popular choice in various industries. Firstly, stainless steel sheets have excellent corrosion resistance properties, which is particularly crucial in environments where exposure to moisture or chemicals is common. This resistance to corrosion ensures that stainless steel sheets maintain their structural integrity and aesthetic appeal over an extended period of time. Another key advantage of stainless steel sheets is their high strength-to-weight ratio. Stainless steel is renowned for its durability and strength, allowing manufacturers to use thinner sheets without sacrificing structural integrity. This not only reduces material costs but also makes stainless steel sheets easier to handle and install. Furthermore, stainless steel sheets are highly versatile and can be customized to meet specific requirements. They can be easily formed, welded, and fabricated into different shapes and sizes, making them suitable for a wide range of applications. Stainless steel sheets are available in various finishes, such as brushed, mirror, or satin, allowing for aesthetic customization as well. In terms of hygiene, stainless steel sheets offer exceptional cleanliness and ease of maintenance. Their smooth, non-porous surface prevents the buildup of bacteria, dirt, or contaminants, making them suitable for applications in the food and healthcare industries. Additionally, stainless steel sheets are resistant to high temperatures, making them ideal for use in heat-intensive applications such as industrial ovens or automotive components. Lastly, stainless steel sheets have good sustainability credentials. They are 100% recyclable, allowing for the conservation of resources and reducing environmental impact. Moreover, stainless steel is composed of a high percentage of recycled content, further enhancing its eco-friendly characteristics. Overall, stainless steel sheets outperform other types of sheet metals in terms of corrosion resistance, strength-to-weight ratio, versatility, hygiene, and sustainability. These qualities make stainless steel sheets a top choice for applications in various industries, including construction, automotive, aerospace, food processing, and many more.

- Q: What are the common uses of stainless steel sheets in the automotive industry?

- Stainless steel sheets find numerous applications in the automotive industry due to their unique properties and characteristics. Here are some common uses of stainless steel sheets in this industry: 1. Exhaust Systems: Stainless steel sheets are extensively used for manufacturing exhaust systems in vehicles. The high-temperature resistance, corrosion resistance, and durability of stainless steel make it an ideal choice for this application. 2. Body Panels: Stainless steel sheets are often used for manufacturing body panels, such as fenders, hoods, and doors. The strength, impact resistance, and aesthetic appeal of stainless steel make it a popular material for enhancing the durability and appearance of vehicles. 3. Structural Components: Stainless steel sheets are utilized in the fabrication of various structural components in automotive applications. These may include chassis, brackets, reinforcements, and frame parts. Stainless steel's high strength-to-weight ratio and excellent mechanical properties make it suitable for enhancing the overall stability and strength of the vehicle. 4. Fuel Tanks: Stainless steel sheets are frequently used for manufacturing fuel tanks in automobiles. Stainless steel's resistance to corrosion, particularly against chemicals present in fuels, ensures long-lasting and leak-free fuel storage. 5. Heat Shields: Stainless steel sheets are employed in the production of heat shields to protect sensitive components from excessive heat generated by the engine or exhaust system. Stainless steel's excellent thermal conductivity and resistance to high temperatures make it an ideal material for this purpose. 6. Fasteners and Clamps: Stainless steel sheets are used to manufacture various fasteners, clamps, and brackets in automotive applications. These components require high strength, corrosion resistance, and durability, which stainless steel provides. 7. Trim and Decorative Accents: Stainless steel sheets are often utilized for trim and decorative accents in vehicles. The aesthetic appeal, shine, and corrosion resistance of stainless steel add a touch of elegance and durability to the vehicle's interior and exterior. In summary, stainless steel sheets find a wide range of applications in the automotive industry, including exhaust systems, body panels, structural components, fuel tanks, heat shields, fasteners, clamps, and trim. The unique properties of stainless steel, such as corrosion resistance, high strength, durability, and aesthetic appeal, make it a preferred material for numerous automotive applications.

- Q: What are the features of stainless steel plates?

- Stainless steel plate has a smooth surface, high plasticity, toughness and mechanical strength, corrosion of acid, alkaline gas, solution and other medium. It is an alloy steel which is not easily rusted, but it is not absolutely rusty. Stainless steel plate refers to the atmosphere, steam and water and other weak medium corrosion of steel plate, and acid resistant steel plate refers to acid, alkali, salt and other chemical corrosive medium corrosion of steel plate. Stainless steel plate has been published since the beginning of twentieth Century, and now has a history of more than 1 centuries.

- Q: How are stainless steel sheets made?

- Stainless steel sheets undergo a process called hot rolling to be produced. This starts by melting iron, nickel, chromium, and other elements in an electric arc furnace. The resulting mixture is then cast into large rectangular blocks known as slabs. The slabs are subjected to high temperatures and passed through a series of hot rolling mills. These mills consist of large rollers that gradually decrease the slab's thickness while increasing its length and width. As the slab goes through each rolling mill, it is constantly squeezed by the rollers, resulting in a thinner and longer sheet. Following the hot rolling process, the stainless steel sheet goes through annealing. This involves heating the sheet to a specific temperature and then allowing it to cool slowly. This process helps release internal stresses and enhance the material's mechanical properties. Next comes pickling, where the sheet is submerged in an acid solution to eliminate any surface impurities and oxides. This improves the appearance and corrosion resistance of the stainless steel. Once the pickling process is done, the sheet undergoes cold rolling. Cold rolling further decreases the sheet's thickness and improves its surface finish. This is done at room temperature, increasing the hardness and strength of the stainless steel. Lastly, the stainless steel sheet undergoes various finishing processes. These may include cutting to size, leveling, surface polishing, and coating to enhance appearance or protect against corrosion. In conclusion, the manufacturing process of stainless steel sheets involves a combination of melting, casting, hot rolling, annealing, pickling, cold rolling, and finishing processes. This ensures that the final product meets the desired specifications in terms of thickness, strength, and surface finish.

- Q: How do you calculate the weight of a stainless steel sheet?

- To calculate the weight of a stainless steel sheet, you need to know its dimensions (length, width, and thickness) and the specific gravity of stainless steel. First, determine the volume of the stainless steel sheet by multiplying the length, width, and thickness together. This will give you the volume in cubic units. Next, multiply the volume by the specific gravity of stainless steel, which is typically around 7.93 g/cm³ (grams per cubic centimeter). This will give you the weight of the stainless steel sheet in grams. To convert the weight to a different unit, such as kilograms or pounds, divide the weight in grams by the appropriate conversion factor. For example, to convert grams to kilograms, divide by 1000. To convert grams to pounds, divide by 453.59237. It is important to note that this calculation provides an estimate of the weight, as there may be slight variations in the specific gravity of stainless steel depending on the exact alloy and composition of the sheet.

- Q: How do you determine the grade of a stainless steel sheet?

- The grade of a stainless steel sheet is determined based on its composition, physical properties, and performance characteristics. It is typically identified by a numerical code, such as 304 or 316, which indicates the specific alloy and its respective properties. This information can be obtained through various methods, including visual inspection, chemical analysis, and referencing industry standards and specifications.

- Q: Can stainless steel sheets be used for architectural canopies?

- Architectural canopies can indeed make use of stainless steel sheets. This versatile material offers numerous advantages in architectural applications, including canopies. To begin with, stainless steel possesses great durability and resistance to corrosion, making it ideal for outdoor installations. This ensures that the canopy will endure harsh weather conditions and maintain its appearance over time. Furthermore, stainless steel boasts a sleek and contemporary aesthetic which can enhance the overall design of the canopy. It can be polished to a mirror-like finish or brushed to create a distinctive texture, giving architects a range of options to achieve their desired look. In addition, stainless steel sheets are available in various thicknesses, allowing for customization based on the specific requirements of the canopy. This flexibility guarantees that the material can support the weight of the structure and any additional elements, such as lighting or signage. Moreover, stainless steel is an environmentally-friendly choice for architectural canopies as it is fully recyclable. This aligns with the increasing demand for sustainable construction materials and practices. To summarize, stainless steel sheets are a popular and suitable choice for architectural canopies due to their durability, aesthetic appeal, flexibility, and sustainability.

- Q: Are stainless steel sheets good for high-temperature applications?

- Stainless steel sheets prove to be an exceptional choice for applications at high temperatures. With a high melting point that typically ranges from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), stainless steel becomes suitable for environments with elevated temperatures. Moreover, this type of steel displays remarkable resistance to oxidation when subjected to high temperatures, effectively preventing the formation of scales or rust that could potentially weaken the material. Additionally, stainless steel boasts good thermal conductivity, facilitating efficient heat transfer. These remarkable attributes establish stainless steel sheets as a dependable option for a diverse range of high-temperature applications, such as industrial furnaces, heat exchangers, boilers, and exhaust systems.

Send your message to us

304 Stainless Steel Metal Sheet CNBM in China

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t

- Supply Capability:

- 35000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords