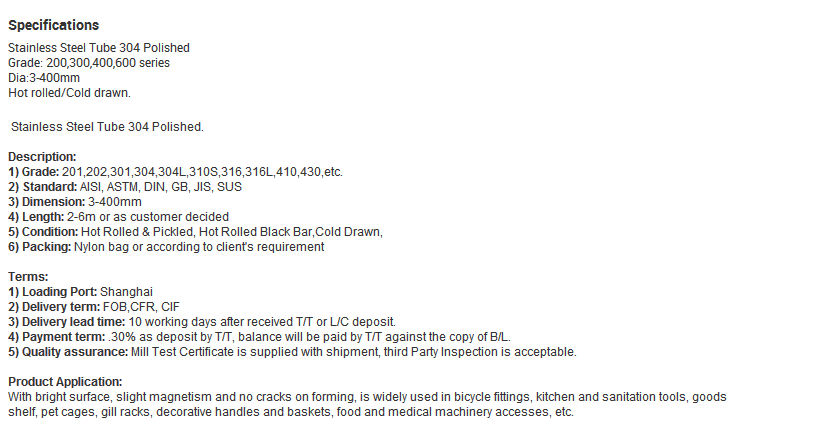

Stainless Steel Tube 304/316L Polished Welded Seamless Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q:Can stainless steel pipes be used for outdoor handrails?

- Indeed, outdoor handrails can be constructed using stainless steel pipes. The reason for stainless steel's prevalence in outdoor settings is its exceptional robustness, resistance to corrosion, and attractive appearance. It remains unscathed even in the face of inclement weather conditions like rain, snow, and exposure to ultraviolet rays, ensuring that it neither rusts nor degrades. Moreover, stainless steel handrails necessitate minimal upkeep and can endure intense usage without faltering. Consequently, they represent a dependable and enduring alternative for outdoor handrails, guaranteeing safety while infusing a contemporary vibe into any given area.

- Q:Are stainless steel pipes suitable for industrial applications?

- Stainless steel pipes excel in industrial settings due to their exceptional corrosion resistance, rendering them a favored option across various industries such as chemical, petrochemical, oil and gas, pharmaceutical, food and beverage, and more. These pipes can endure elevated temperatures and pressures, making them perfect for transporting fluids and gases in industrial procedures. Moreover, their durability, strength, and prolonged lifespan become pivotal in heavy-duty industrial scenarios. Furthermore, stainless steel pipes necessitate effortless maintenance and cleaning, mitigating the risk of contamination in industries that mandate stringent hygiene standards. In summary, stainless steel pipes present myriad advantages that render them highly suitable and extensively employed in industrial applications.

- Q:What is the maximum allowable working pressure for stainless steel pipes?

- Several factors, including the grade of stainless steel, pipe size, and operating temperature, determine the maximum allowable working pressure for stainless steel pipes. Compared to other materials, stainless steel pipes generally have higher pressure ratings due to their exceptional resistance to corrosion. Standards and codes, such as ASME B31.3 and B31.1, typically determine the maximum allowable working pressure (MAWP). These codes provide guidelines for the fabrication, design, and installation of piping systems. For instance, ASME B31.3 offers tables and formulas that allow for the calculation of the maximum allowable working pressure based on the temperature, wall thickness, and material properties of the stainless steel pipe. Additionally, the code takes into account safety factors, corrosion allowances, and the specific service conditions. To determine the maximum allowable working pressure of the stainless steel pipe being used, it is crucial to consult the relevant standards and codes. Working pressures can vary significantly depending on factors such as pipe grade, dimensions, and intended application.

- Q:Can stainless steel pipes be insulated with polyvinyl chloride?

- No, stainless steel pipes cannot be insulated with polyvinyl chloride.

- Q:How do you clean and maintain stainless steel pipes?

- To clean and maintain stainless steel pipes, start by wiping them down with a mild detergent or soap and warm water using a soft cloth or sponge. Rinse thoroughly and dry with a clean cloth to prevent water spots. Avoid using abrasive cleaners or scrub brushes that can scratch the surface. Regularly inspect the pipes for any signs of corrosion, staining, or damage, and promptly address any issues to prevent further deterioration. Additionally, applying a stainless steel cleaner or polish can help remove stubborn stains and restore the shine of the pipes.

- Q:What is the difference between seamless and hot-expanded stainless steel pipes?

- The main difference between seamless and hot-expanded stainless steel pipes lies in their manufacturing processes. Seamless pipes are created by piercing a solid billet of stainless steel, while hot-expanded pipes are made by expanding a hollow tube while it is heated. This process results in a larger diameter and thinner wall thickness compared to seamless pipes. Additionally, hot-expanding allows for a wider range of sizes and shapes to be produced.

- Q:What is the difference between 201 and 316 stainless steel pipes?

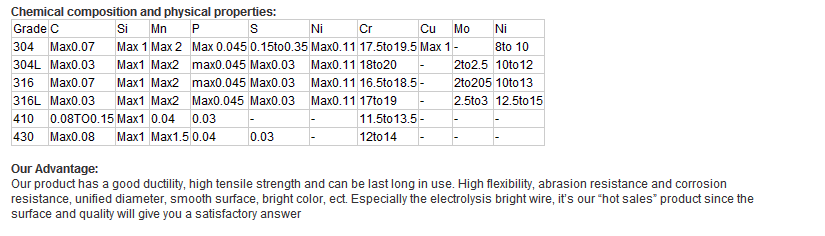

- The chemical composition and respective properties differentiate 201 stainless steel pipes from 316 stainless steel pipes. 201 stainless steel, being lower in grade than 316, contains a higher quantity of manganese and nitrogen, resulting in improved strength and corrosion resistance compared to other lower grade stainless steels. However, it lacks the durability of 316 stainless steel and is more susceptible to corrosion and rusting. On the contrary, 316 stainless steel is a top-notch grade that boasts a higher proportion of chromium and nickel. These elements enhance its corrosion resistance, making it highly resistant to pitting and crevice corrosion, especially in chloride environments. Additionally, 316 stainless steel pipes are more resistant to high temperatures and possess superior strength when compared to 201 stainless steel pipes. Consequently, industries with rigorous demands such as marine, chemical, and medical sectors widely employ 316 stainless steel pipes due to their exceptional corrosion resistance and durability. Conversely, 201 stainless steel pipes, suitable for general applications, are predominantly utilized in less demanding environments where cost-effectiveness is prioritized.

- Q:What are the different grades of stainless steel used for pipes?

- There are several different grades of stainless steel that are commonly used for pipes, each with their own unique properties and characteristics. The most common grades include: 1. Grade 304: This is the most widely used stainless steel grade for pipes. It offers excellent corrosion resistance, high-temperature strength, and good formability. It is commonly used for both indoor and outdoor applications, such as water supply pipes, food processing equipment, and architectural structures. 2. Grade 316: This grade is similar to 304 but contains a higher content of molybdenum, which enhances its corrosion resistance, especially against chlorides and other corrosive chemicals. It is commonly used in marine environments, chemical processing plants, and medical equipment. 3. Grade 321: This grade contains titanium, which stabilizes it against sensitization during welding or high-temperature exposure. It offers excellent resistance to oxidation and can be used in applications where high temperatures are involved, such as exhaust systems and boilers. 4. Grade 409: This grade is commonly used for pipes in automotive exhaust systems due to its excellent heat resistance and durability. It is also resistant to corrosion from road salts and other harsh chemicals. 5. Grade 347: Similar to grade 321, this grade contains niobium, which provides additional stabilization against sensitization. It is commonly used in high-temperature applications where resistance to intergranular corrosion is required, such as in aircraft and jet engine components. These are just a few examples of the different grades of stainless steel used for pipes. The specific grade chosen for a particular application depends on factors such as the environment, temperature, corrosion resistance requirements, and mechanical properties needed.

- Q:Can stainless steel pipes be used in marine environments?

- Indeed, stainless steel pipes are perfectly suitable for marine environments. With its exceptional resistance to corrosion and rust, stainless steel emerges as the ideal material for marine applications. It can effectively endure the severe conditions of saltwater, including elevated humidity levels, moisture, and exposure to diverse chemicals. Given their durability and enduring performance, stainless steel pipes are extensively utilized in marine vessels, offshore platforms, and various other marine structures. These pipes offer remarkable strength and reliability, even in the face of challenging environments, thus rendering them the preferred choice for marine applications.

- Q:Are stainless steel pipelines buried in need of corrosion protection?

- In the aqueous medium such as Cl-, the localized destruction of the passive film due to acidification of the dielectric solution in the crevice (increasing of Cl- concentration, decrease in pH value) and hypoxia (oxygen concentration cell, gap hypoxia). The most fundamental is to eliminate the gap from the structure is designed to avoid the gap of the heat exchanger tube is connected with the gap at the gap on the tube plate, flange, gaskets, bolts, rivets, to take appropriate measures to prevent.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless Steel Tube 304/316L Polished Welded Seamless Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 kg

- Supply Capability:

- 1000 kg/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords