3003 H24 PE and PVDF Color Coated Aluminum Coil of Aluminum 6 Wide for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description:

3003 H24 PE and PVDF color coated aluminum coil for aluminum composite panel

We provide a series of aluminum products,such as aluminum circle,aluminum sheet,aluminum coil,mirror aluminum plate,embossed aluminum plate,aluminum plate,color aluminum plate,etc .

1) PE coated aluminum coil is made via rolling painting and baking, it has various bright colors with small color differences. It is resistant against impact and easy to be machined. All properties meet or surpass the national standard. the product is widely used in indoor and shop front decoration, ceiling roof tile, wall panel, advertisement board, counter, household electric apparatus, and inner and outer decoration of cars and ships.

2) The main raw material of PVDF fluorine carbon coating is PVDF fluorine carbon resin-polyvinylidene fluoride fiber. By maximum electric performance of fluorine atom, a stable and high fluorine bond can be formed. In addition to, the unique equal symmetrical molecular structure, the product are given with outstanding weathering resistance, excellent ultraviolet radiation resistance, and highly endurable corrosion resistance. The outdoor product color and brightness can be maintained for over 20 years. Because of high weather and impact resistance and the high pliability, the product has excellent machining property, and the coated colored panel can be further treated for pattern pressing. This product can be provided in two types: traditional fluorine carbon and nanometer fluorine carbon.

Raw Material

Aluminum Grade:1100,3003,5005.

Temper:H14,H16,H18,H24,etc.

Surface Coating: PE&PVDF

Specification

Thickness:0.024-0.7mm

Coil Width:56-2000mm

Coating Thickness:18-30um.

ID:405/505mm

Coil Weight:0.15-3MT

Gloss:10-90%(EN ISO-2813:1994)

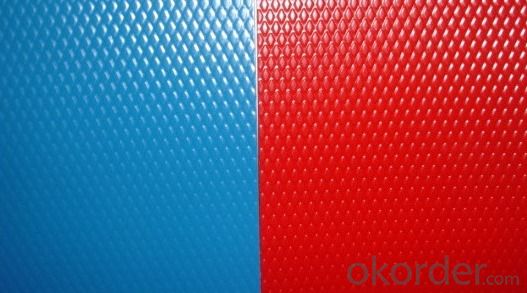

Color: solid, metallic, glossy, real stone, timber design, embossed, etc.

You can choose our color chart, or we adjust the special color as the samples you offer.

Product Feature

1) High gloss

2) High flexibility

3) Excellent impact resistance

4) Excellent weather-proof resistance

5) Anti-ultraviolet

6) High erosion resistance

7) Stable color and gloss

8)Good mechanical processing performance

Coating Characteristic Table

Pre-painted Aluminum Coil | |

Grade and Temper | Alloys: 1050, 1100, 3003,3005,3105, 5005,5052,6061,6063,8011,etc Temper: 0-H112 |

Widths | 35mm -1700 mm available |

Thickness | 0.25mm - 4.0mm |

Coating | PE, PVDF or Customize |

Coil Specifications | I.D.: 405mm, 505mm O.D.: 800mm – 1270mm |

Color | Customized |

Packing Detail | Wooden pallet either eye to wall or eye to sky |

Application | Aluminum Suspended Ceiling ,Aluminum Sandwich Panel, Wall Cladding Panel, Roller Shutter, Metal Roofing, Conner Bead, etc |

Coating Type

| Test Item | Coating | |||||||

| PVDF | PE | |||||||

| Double layers | Three layers | |||||||

| Coating Thickness | ≥24 | ≥30 | ≥18 | |||||

| Glossy Tolerance | While 60°gloosy value ≥80 unit,tolerance±10 unit | |||||||

| While 60°gloosy value ≥20-80 unit,tolerance±7 unit | ||||||||

| While 60°gloosy value<20 unit,tolerance±5 unit | ||||||||

| Pencil Hardness | ≥1H | ≥2H | ||||||

| Flexibility of coating | While ≤2T,coating no crack or peer off | |||||||

| Adhesive property | 0 or 1 grade | |||||||

| Impact resistance | coating no crack no peer off | |||||||

| Acid resistance | Surface immersed with 5% HCL(V/V) for 48H | Surface immersed with 2% HCL(V/V) | ||||||

| without change | for 24H without change | |||||||

| Solvent Resistance | Brushing 200 times with butanone no appearance | Brushing 100 times with butanone no | ||||||

| to bottom | appearance to bottom | |||||||

| Chromatism | The coating color is almost the same as confirmed by buyer and seller,the color difference tested by | |||||||

| colorimeter between single coating and sample is less than 1.2(ΔE≤1.2),same lot products color difference | ||||||||

| ΔE≤1.0 | ||||||||

| Salt Fog Resistance | Outside 2mm the line which is scratched,no corrosion | |||||||

| and coating peel off | ||||||||

| Moisture Resistance | Coating change is less than 1 grade after 1000 hours | |||||||

| humidity test | ||||||||

| Weather Resistance | After 2000 hours xenon lamp shining test(artificially | |||||||

| accelerating ageing test),no powder come into being, | ||||||||

| glossy retention rate(after and before test percent rate) | ||||||||

| ≥85%,color change degree at least reaching to 1 grade | ||||||||

| Note:The test is as per China National Standard and Nonferrous Metals Industry Standard for color coated aluminum | ||||||||

| coil and ACP | ||||||||

FAQ of Coated Aluminum Coil for Aluminum Composite Panel

1.Superior quality of raw material.

2.Reasonable and stable chemical composition.

3.Accurate tolerance.

4.Goode mechanical property.

5.We have the certificate of ISO9001.

- Q: What’s the standard of tensile strength and ductility of aluminum coil 3003?

- Detailed description can help resolve problems quickly. Performance and status is a related. As aluminum coil is usually semi-hard, the tensile strength is greater than or equals 150, ductility is greater than or equals 12.

- Q: How do aluminum coils contribute to sustainable transportation?

- Aluminum coils play a crucial role in promoting sustainable transportation in several ways. Firstly, aluminum is a lightweight material, making it an ideal choice for various components in vehicles. By replacing heavier materials such as steel, aluminum coils help to reduce the overall weight of the vehicle. This, in turn, improves fuel efficiency and reduces greenhouse gas emissions. Furthermore, the use of aluminum coils in vehicle manufacturing helps to enhance the durability and longevity of the vehicle. Aluminum is highly resistant to corrosion, which is particularly beneficial in areas with harsh weather conditions or high levels of road salt. This longevity means that vehicles made with aluminum coils require less frequent repairs and replacements, reducing the amount of waste and resources consumed over the lifetime of the vehicle. In addition, the recyclability of aluminum is another significant factor in sustainable transportation. Aluminum is one of the most recyclable materials on the planet, with almost 75% of all aluminum ever produced still in use today. By using aluminum coils, manufacturers can incorporate recycled aluminum into their production processes, reducing the need for primary aluminum extraction. This not only conserves natural resources but also reduces energy consumption and greenhouse gas emissions associated with aluminum production. Moreover, aluminum coils contribute to sustainable transportation by enabling the advancement of electric vehicles (EVs). The lightweight nature of aluminum helps to improve the range and efficiency of EVs by reducing their energy consumption. Additionally, aluminum's excellent thermal conductivity allows for better heat dissipation in EV batteries, enhancing their performance and lifespan. Overall, the use of aluminum coils in transportation supports sustainability efforts by reducing vehicle weight, improving fuel efficiency, increasing durability, promoting recycling, and enabling the growth of electric vehicles. As the transportation sector continues to strive for reduced emissions and increased efficiency, aluminum coils will continue to play a vital role in achieving these sustainability goals.

- Q: What are the common recycling methods for aluminum coils?

- There are several common recycling methods for aluminum coils. One of the most widely used methods is mechanical recycling, which involves shredding the aluminum coils into small pieces and then melting them down to form new aluminum coils. This method is efficient and cost-effective, as it allows for the reuse of the aluminum material without compromising its quality. Another method is called pyrolysis, which involves heating the aluminum coils at high temperatures in the absence of oxygen. This process breaks down the aluminum into its constituent elements, allowing for the recovery of valuable metals and other byproducts. Chemical recycling is another method that can be used for aluminum coil recycling. This involves dissolving the aluminum coils in a chemical solution to separate the aluminum from other materials. The resulting aluminum can then be used to manufacture new coils. Finally, there is also a method called smelting, which involves melting the aluminum coils and separating impurities through a process called electrolysis. This method allows for the recovery of pure aluminum, which can be used to make new coils. Overall, these recycling methods help to reduce the environmental impact of aluminum coil production by conserving resources and minimizing waste. They also contribute to the sustainability of the aluminum industry by promoting the reuse of materials and reducing the need for virgin aluminum production.

- Q: What are the common transportation methods for aluminum coils?

- The common transportation methods for aluminum coils include trucking, rail shipping, and shipping via container vessels.

- Q: Can aluminum coils be used for pharmaceutical packaging?

- Yes, aluminum coils can be used for pharmaceutical packaging. Aluminum is a popular choice for pharmaceutical packaging due to its various beneficial properties. It is lightweight, corrosion-resistant, and has excellent barrier properties, making it ideal for protecting pharmaceutical products from external factors such as moisture, oxygen, and light. Aluminum coils can be easily formed into different shapes and sizes, providing versatility for packaging needs. Additionally, aluminum is non-toxic and non-reactive, ensuring the safety and integrity of pharmaceutical products.

- Q: Are there any specific certifications or qualifications required for aluminum coil suppliers?

- Certifications and qualifications that are essential for aluminum coil suppliers do exist. The ISO 9001 certification is a vital one for these suppliers as it guarantees the implementation of a quality management system and adherence to international quality standards. When a supplier possesses this certification, it demonstrates their effective quality control processes, consistent product performance, and ability to satisfy customers. Another critical qualification for aluminum coil suppliers is the AS9100 certification, particularly for those serving the aerospace industry. This certification verifies that the supplier has fulfilled the industry-specific requirements for quality management systems, including rigorous quality control, traceability, and compliance with industry standards. Moreover, aluminum coil suppliers may also need to conform to industry-specific standards like the ASTM standards or the REACH regulations of the European Union concerning chemical substances. These standards ensure that the supplier's products fulfill the necessary specifications and are safe to use in various applications. Furthermore, certain aluminum coil suppliers may possess specialized certifications or qualifications tailored to specific industries or applications. For instance, suppliers serving the automotive industry may hold certifications like the IATF 16949 certification, which demonstrates their ability to meet the demanding requirements of automotive manufacturers. In conclusion, while the specific certifications and qualifications required may vary depending on the industry and application, it is crucial for aluminum coil suppliers to possess certifications like ISO 9001 and industry-specific certifications to ensure their products meet the required quality standards and comply with relevant regulations.

- Q: How is the welding performance of 3003 aluminum coil?

- 3003 aluminum coil, a kind of rust-proof aluminum, belongs to AL-Mn series alloy. With low intensity (slightly higher than commercial purity aluminum), it cannot endure heat treatment, so cold processing is adopted to increase its mechanical property: high plasticity in annealing and semi-cold hardening, low plasticity in cold hardening, good corrosion resistance., good weldability and bad machinability. It is mainly used for low load part in liquid or gaseous medium requiring high plasticity and good weldability, such as fuel tanks, gasoline or lubricant conduit. It can also be used for liquid containers and other deep drawing small load parts made by deep drawing. Aluminum wire can be used to make the rivet.3003 aluminum sheet has good formability, weldability and corrosion resistance. It is used to process parts which require good formability, corrosion resistance and weldability and lower intensity than 1xxx series alloy, such as such as kitchenware, food and chemical products processing and storage equipment, groove and tank to transport liquid product, pressure vessel and pipe processed from thin plate, cooling fin, make-up board, photocopier rollers and ship material.

- Q: Can aluminum coils be welded or joined?

- Aluminum coils have the capability to be welded or joined. Aluminum, being a highly weldable metal, can be easily joined through the utilization of different welding techniques. TIG welding, MIG welding, and resistance welding are the most commonly employed methods for welding aluminum coils. TIG welding is a precise and adaptable technique that employs a non-consumable tungsten electrode to generate the arc. This method is extensively utilized in welding aluminum coils due to its ability to offer exceptional control over the welding process, resulting in welds of high quality and strength. On the other hand, MIG welding employs a consumable wire electrode and a shielding gas to safeguard the weld zone from atmospheric contamination. This technique is faster compared to TIG welding and is often favored for larger production runs. Resistance welding is yet another prevalent method employed for joining aluminum coils. It involves the passage of an electric current through the overlapping metal surfaces to generate heat and pressure, thereby creating a robust weld joint. This technique is commonly used in industries that require high-speed production. It is important to note that welding aluminum coils necessitates specific techniques and considerations due to the distinctive properties of the metal. Aluminum possesses a lower melting point and higher thermal conductivity than other metals, which can make the welding process more challenging. Proper cleaning, preheating, and the selection of suitable filler materials are crucial in achieving successful welds. To summarize, aluminum coils can be welded or joined using various techniques such as TIG welding, MIG welding, and resistance welding. However, it is imperative to adhere to proper procedures and take into account the specific properties of aluminum to ensure the creation of strong and dependable welds.

- Q: for purchasing aluminium are the grades to be mentioned

- If it is a product for work, yes engineers and purchasers specify the grades. If for hobby then it is up to you. Common extruded shapes (beams, tubes, angles) - 6061-T6 - 6063-T5 -T6 specifies tempering class. Actually both alloys come in various T4, T5, etc., the above are just two common combinations. 6061 is a little stronger, and T6 gets its strength up quite good. Beware that welded joints are weaker since heat removes the strength from tempering. Some common sheets - 6061 (strength) - 5052 (strength, welds better than 6xxx, good formability) - 5068 (some call it 'marine grade' for corrosion resistance) Sheets can come in many alloys.... you may get cheaper grades if you don't need one of these. (if you are casting - there's whole other system of grades.) The above are just common grades. For high strength requirement you may need a specific grade in the 7xxx family.

- Q: Can aluminum coils be used in the production of aluminum sunshades?

- Aluminum sunshades can indeed incorporate aluminum coils. In the manufacturing process of these sunshades, aluminum coils serve as the initial material. These coils are crafted from top-notch aluminum, renowned for its lightweight and resilient properties. They are subsequently formed and molded into the desired shape for the sunshade, whether it is slats, louvers, or a solid panel. The corrosion resistance and ability to withstand diverse weather conditions are among the reasons why aluminum is a favored choice for sunshades. It is worth noting that aluminum is easily recyclable, rendering it an environmentally friendly material for sunshade production. All in all, aluminum coils are indispensable elements in the creation of aluminum sunshades, contributing to their strength, durability, and aesthetic allure.

Send your message to us

3003 H24 PE and PVDF Color Coated Aluminum Coil of Aluminum 6 Wide for Aluminum Composite Panel

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords