3003 H14 Aluminum Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium Coil Used for Building Material

l Product Introduction

It is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

1. Temper: O, F, HXX

2. Thickness: Thickness

3. Width: 1000-1500mm

4. Type: Coil/Roll

5. Surface Treatment: mill finished

6. Application: Decoration, packaging, printing, covering

7. Standard size: Upon customer's demand

8. Quantity: 18tons(±10%)in one 20 feet container

l Product Description

Specification:

Aluminium Coil Used for Building Material | ||||||||||||||||

Aluminium Coils, non-alloy and alloy products have many different applications, they are used windly throughout construction, building, decoration, lighting, metal nameplate, aircraft and aerospace structures, etc. | ||||||||||||||||

Specification | ||||||||||||||||

ALLOY | TEMPER | THICKNESS | WIDTH(mm) | LENGTH(mm) | ||||||||||||

1050, 1060, 1070, | O, F, H12, 114, H18, H22, H24, H26, H32, H34, H36, H111, H112, H314 | 3.0-10.0 | 1000--1500mm | in Coil | ||||||||||||

chemical composition | ||||||||||||||||

Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ca | V | Ti | Other | Min.Al | |||

1050 | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.50 | |||

1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | - | - | 0.05 | - | 0.05 | 0.03 | 0.03 | 99.60 | |||

1070 | 0.20 | 0.25 | 0.04 | 0.03 | 0.03 | - | - | 0.04 | - | 0.05 | 0.03 | 0.03 | 99.70 | |||

1100 | 0.95 | 0.05-0.2 | 0.05 | - | - | - | 0.10 | - | - | - | 0.05 | 99.00 | ||||

3003 | 0.60 | 0.70 | 0.5-0.2 | 1.0-1.5 | - | - | - | 0.10 | - | - | - | 0.15 | 96.95-96.75 | |||

3004 | 0.30 | 0.70 | 0.25 | 1.0-1.5 | 0.8-1.3 | - | - | 0.25 | - | - | - | 0.15 | 96.55-95.55 | |||

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payments

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323. |

l CNBM World Wide

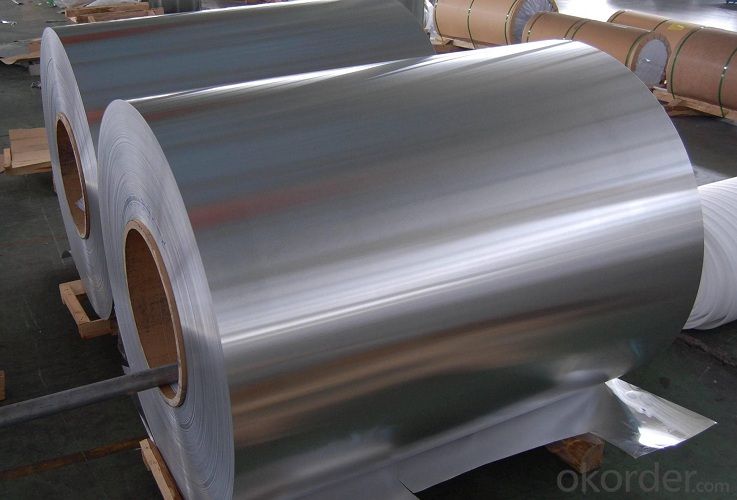

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 2.5 tons

Q: What are your payment terms?

A: We accept L/C, T/T

- Q: How are aluminum coils joined or welded?

- Aluminum coils can undergo various methods of joining or welding, depending on the specific application and desired outcome. Some commonly employed techniques are: 1. Mechanical fastening: This involves physically fastening the aluminum coils together using bolts, screws, or rivets. Mechanical fastening is a cost-effective and straightforward method suitable for thin coils or temporary connections. 2. Adhesive bonding: Specialized adhesives are used to bond aluminum coils together in adhesive bonding. This method creates a strong and durable joint, evenly distributing stress across the entire bond area. Adhesive bonding is often used when aesthetics, weight reduction, or vibration dampening are important considerations. 3. Resistance welding: Resistance welding employs an electric current to generate heat and pressure at the joint, effectively welding the aluminum coils. This method is particularly suitable for high-speed production lines, providing a strong and reliable joint. However, it requires specialized equipment and may not be suitable for all aluminum alloys. 4. Laser welding: Laser welding is a precise and efficient method that utilizes a laser beam to melt and join the aluminum coils. This technique allows for precise control of heat input, resulting in minimal distortion and excellent weld quality. Laser welding is commonly used in industries where high precision and aesthetic appearance are crucial, such as automotive and aerospace. 5. Friction stir welding: Friction stir welding is a solid-state joining process that employs a rotating tool to generate heat and friction, effectively welding the aluminum coils without melting the material. This method produces strong and high-quality welds with minimal distortion and no need for additional filler material. Friction stir welding is commonly used in industries that require excellent mechanical properties and high productivity, such as shipbuilding and railway construction. Overall, the choice of joining or welding method for aluminum coils depends on factors such as desired joint strength, application requirements, production volume, and available equipment and expertise.

- Q: What are the common cutting and shaping methods for aluminum coils?

- The common cutting and shaping methods for aluminum coils include shearing, blanking, punching, and forming.

- Q: Is it possible to use a crowbar as a tool for opening an aluminum coil?

- <p>While a crowbar can be used to apply force to open various objects, it may not be the most suitable tool for opening an aluminum coil. Aluminum coils can be sharp and using a crowbar could lead to injury or damage to the coil. It's recommended to use gloves and a pair of pliers or a coil cutter specifically designed for handling aluminum coils to ensure safety and avoid damaging the material.</p>

- Q: A nitrate is added with sodium hydroxide, then a piece of aluminum foil. After warming the mixture, ammonia gas is released.A source tells me that aluminum reduces nitrate ion into the ammonium ion. How is this done?

- Aluminum is an active metal and wants to be ionized. Al -- Al(3+) + 3e(-) ?n basic media, tetrahydroxoaluminate complex will be formed: Al(3+) + 4OH(-) -- Al(OH)4(-) ======================================... Al + 4OH(-) -- Al(OH)4(-) + 3e(-) Nitrate is reduced to ammonia in basic media, ammonium in acidic media: N(5+) + 8e(-) -- N(3-) NO3(-) + 8e(-) + 10H(+) -- NH4(+) + 3H2O in basic media, we add base (OH-) to both sides: NO3(-) + 8e(-) + 11OH(-) + 10H(+) -- NH4(+) + 3H2O + 11OH(-) NO3(-) + 8e(-) + OH(-) + 10H2O --- NH3 + 4H2O + 10OH(-) ======================================... NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) Now, to the balancing of these two redox half reactions: Al + 4OH(-) -- Al(OH)4(-) + 3e(-) NO3(-) + 8e(-)+ 6H2O -- NH3 + 9OH(-) ============================= 8Al + 32OH(-) -- 8Al(OH)4(-) + 24e(-) 3NO3(-) + 24e(-) + 18H2O -- 3NH3 + 27OH(-) ================================== 8Al + 3NO3(-) + 32OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 + 27OH(-) //////////////////////////////////////... 8Al + 3NO3(-) + 5OH(-) + 18H2O -- 8Al(OH)4(-) + 3NH3 Hope this helps.

- Q: What are aluminum coils used for?

- Aluminum coils are commonly used in various industries, such as construction, automotive, and HVAC, for their excellent thermal conductivity and corrosion resistance properties. They are primarily used for manufacturing heat exchangers, air conditioning systems, refrigeration units, and other heat transfer applications.

- Q: This question is asking about the potential negative effects or hazards associated with the use of aluminum coils.

- <p>The use of aluminum coils can pose certain risks and dangers, primarily due to their high thermal conductivity and reactivity. When used in cooking or heating applications, aluminum coils can cause uneven heat distribution, which may lead to burning or melting of food. Additionally, aluminum can react with acidic or alkaline foods, potentially leaching aluminum into the food and causing health concerns such as neurological disorders and bone diseases. Moreover, aluminum coils can corrode over time, especially when exposed to moisture or certain chemicals, which can weaken their structure and pose a risk of breakage or injury. It's important to use aluminum coils appropriately and to monitor their condition regularly to minimize these risks.</p>

- Q: How are aluminum coils tested for surface roughness?

- Aluminum coils are tested for surface roughness through various methods, including visual inspection, mechanical profiling, and non-destructive testing techniques. Visual inspection involves examining the surface with the naked eye to identify any visible roughness or irregularities. Mechanical profiling employs instruments like profilometers to measure the surface roughness parameters, such as Ra (average roughness) or Rz (mean peak-to-valley height). Non-destructive testing methods, like ultrasonic or eddy current testing, can also be utilized to detect surface irregularities without causing any damage to the coil. These tests ensure that the aluminum coils meet the required surface roughness specifications for their intended applications.

- Q: How do aluminum coils contribute to lightweight construction?

- Aluminum coils contribute to lightweight construction by providing a material that is significantly lighter than other metals such as steel. This allows for the reduction of overall weight in structures, vehicles, and appliances, leading to increased fuel efficiency, improved performance, and lower environmental impact. Additionally, aluminum coils have high strength-to-weight ratio, making them ideal for applications where strength is required without compromising on weight.

- Q: For the reaction at the anode:Al ----gt; Al3+ + 3eHowever, at the anode, oxygen are also produced and forms aluminium oxide(Al2O3) with aluminium.Are Oxygen produced by oxidation of water by electrolysis? or some reaction else?If Oxygen are produced by oxidation of water, then why it can be oxidise sinceAl ----gt; Al3+ + 3e E^0= + 1.66V2H2O ---gt; O2 + 4H+ + 4e E^0= - 1.23V(if refers to E null value) Oxygen should only be produced after all the Al have been finish oxidised.Both reaction happen at the same time? Is it possible?

- with respect to your massege, i must say that it depends of what electrode you choice for your work. but with refer to E i think oxidation of watter do not interference with oxidation of Al and only oxidation of Al happen .

- Q: I'm trying to cast aluminum using plaster and i was wondering if any one know how much the plaster has to be baked and how to tell if the plaster is dried fully and ways to do it. thx

- When okorder /... Aluminum melts at about 1200 F. Silver at about 1700 F. So this would work fine. You would need a Kiln to heat the investment up to these temps - in a pinch a ceramic kiln would work. If you don't get all the moisture out the mold could explode from steam pressure - be careful - read some books or visit some backyard casting sites. Aluminum is also cast using sand casting techniques.Good luck.

Send your message to us

3003 H14 Aluminum Coil for Building Material

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2.5

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords