Green Diamond PVC Conveyor Belt For Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Green Diamond PVC Conveyor Belt For Light Industry

PVC/PU Conveyor Belt

PVC is widely used in construction because it is durable and easily worked. It can be made softer and more flexible by the addition of plasticizers. In this form, it is used in clothing and upholstery, electrical cable insulation, inflatable products, and many applications in which it replaces rubber.

PVC's biological and chemical resistance and workability have resulted in its use in a wide variety of applications. It is used for sewerage pipes and other pipe applications where cost or vulnerability to corrosion limits the use of metal. With the addition of impact modifiers and stabilizers, it has become a popular material for window- and door frames. By adding plasticizers, it can become flexible enough to be used in cabling applications as a wire insulator.

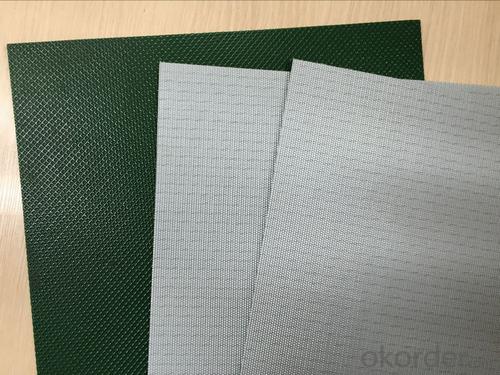

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

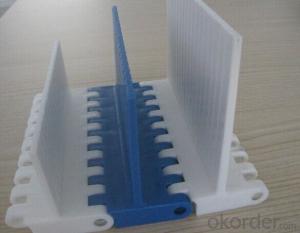

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Please contact us freely if you need any conveyor belt.

- Q: Can olive nets be used to improve fruit set?

- Yes, olive nets can be used to improve fruit set. These nets can help protect olive trees from pests and birds, ensuring that the flowers are not damaged or eaten. By keeping the flowers intact, olive nets promote pollination and increase the chances of successful fruit set.

- Q: Do olive nets protect against hailstorms?

- No, olive nets do not provide protection against hailstorms.

- Q: Are there any specific guidelines for using olive nets on olive trees with specific flowering patterns?

- Yes, there are specific guidelines for using olive nets on olive trees with specific flowering patterns. These guidelines typically recommend the optimal time for installing the nets to protect the blossoms from wind, pests, and excessive sunlight. It is important to consider the specific flowering pattern of the olive trees to ensure effective coverage and prevent any damage to the blossoms during the pollination process.

- Q: Are there any specific techniques for preventing olive net damage from wildlife?

- Yes, there are several specific techniques for preventing olive net damage from wildlife. One commonly used method is installing bird netting or mesh around the olive trees, which acts as a physical barrier to prevent birds from reaching the olives. Another technique is the use of scare devices, such as reflective tape, noise-making devices, or predator decoys, to deter birds and other wildlife from approaching the olive trees. Additionally, employing bird repellents, such as taste aversion sprays or natural deterrents like grape concentrate, can help discourage wildlife from feeding on the olives. Regular monitoring and early detection of wildlife activity can also be useful in implementing timely preventive measures.

- Q: How do I wipe the paint off the plastic?

- According to the plastic color, the specific way to remove is as follows.(1) water color, you can use detergent or detergent dipped in water directly wash off.(2) oily color, you can use alcohol, oil, paint thinner removal.(3) solidified paint, paint remover can be used, but pay attention to proper amount.

- Q: Are olive nets safe for the tree's branches and foliage?

- Yes, olive nets are generally safe for the tree's branches and foliage. These nets are designed to be lightweight and non-abrasive, allowing for proper air circulation and sunlight penetration while protecting the fruit from birds and insects. However, it's important to ensure that the nets are properly installed and regularly checked to prevent any potential damage or entanglement to the tree's branches and foliage.

- Q: Can olive nets be used to improve fruit coloration?

- Yes, olive nets can be used to improve fruit coloration. Olive nets provide shade to the fruits, reducing sunburn and heat stress, which can lead to better color development in the fruit. Additionally, the nets protect the fruits from pests and birds, allowing them to fully ripen and develop their natural color.

- Q: Can olive nets be used in combination with other pest control methods?

- Yes, olive nets can be used in combination with other pest control methods. Olive nets are primarily used to protect olive trees from birds, but they are not effective against all types of pests. To control other pests such as insects or diseases, additional pest control methods like insecticides or fungicides may need to be used alongside olive nets.

- Q: Waste plastics recycling plant how to solve environmental problems

- Characteristics of plastics:Plastic has excellent chemical stability, corrosion resistance, electrical insulation and shock absorption, sound insulation effect is good sound insulation,, and has good elasticity, good with metal, glass, wood and other materials bonding, easy processing. In the four big industrial materials, the quantity, function, status and application range of plastics are expanding rapidly, leading a large number of metals, wood, paper and so on. They are widely used in various fields of national economy.Hazards of plastic use:However, it is because of some excellent properties of plastics that it is not easy to decay after use or consumption. It has seriously affected the ecological environment of the earth, and has aroused great concern all over the world.

- Q: Are olive nets easy to set up and take down?

- Yes, olive nets are generally easy to set up and take down. They are designed to be lightweight and flexible, allowing for easy installation and removal. Additionally, most olive nets come with user-friendly instructions and simple mechanisms that make the process quick and hassle-free.

Send your message to us

Green Diamond PVC Conveyor Belt For Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords