Malleable Aluminum Strips - 1xxx Series Decorative Embossed Aluminum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminum

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

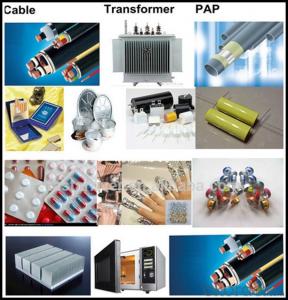

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Advertisement: fascia, shop fronts...

(3).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations..

3. Feature of Aluminum

Aluminium is a very light metal with a specific weight of 2.7 g/cm3, about a third that of steel. For example, the use of aluminium in vehicles reduces dead-weight and energy consumption while increasing load capacity. Its strength can be adapted to the application required by modifying the composition of its alloys.

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? | ||||

A: Normally it would be 40days after received your deposit. | ||||

Q: Can you provide free samples? | ||||

A: Yes, free samples will be sent to you on freight at destination. | ||||

Q: Can I get your latest catalogue? | ||||

A: Yes, it will be sent to you in no time. | ||||

Q: What is the MOQ? | ||||

A: 3 tons | ||||

Q: What are your payment terms? | ||||

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: Can the high frequency of aluminum band replace the high frequency of professional high-power loudspeaker box?

- Can not be replaced, professional speakers generally use the horn loudspeaker, the sound directivity and speaker sensitivity are high, with a sound tweeter transient, clear, but the power and sensitivity of traditional voice Miss horn loudspeaker

- Q: Is there any risk associated with the use of aluminum strips for roofing and siding purposes?

- <p>While aluminum strips are generally safe for roofing and siding, there are a few concerns to consider. Aluminum can expand and contract with temperature changes, which may lead to buckling or warping over time. Additionally, it is a good conductor of heat and electricity, so it may not provide the best insulation or protection against lightning strikes. Aluminum is also prone to denting and can be noisy in heavy rain or hail. However, it is lightweight, durable, and resistant to corrosion, making it a popular choice for many homeowners. Proper installation and maintenance are crucial to minimize these risks.</p>

- Q: Can aluminum strips be recycled repeatedly without any loss in quality?

- <p>Yes, aluminum strips can be recycled indefinitely without losing their quality. Aluminum is a highly recyclable material, and the recycling process does not degrade the metal's properties. In fact, recycled aluminum requires only 5% of the energy needed to produce new aluminum from raw materials. This makes aluminum recycling an environmentally friendly and sustainable practice.</p>

- Q: Is it possible to construct an energy-efficient wall using aluminum strips compared to other materials?

- <p>Aluminum strips alone may not be the best choice for constructing an energy-efficient wall. Aluminum is a good conductor of heat, which means it can transfer heat quickly and isn't ideal for insulation. However, aluminum can be used in combination with insulating materials to enhance energy efficiency. For instance, aluminum composite panels with a core of insulation material can provide both structural strength and thermal insulation. The key to energy-efficient walls is to use materials with high R-values (thermal resistance), such as fiberglass, cellulose, or polyurethane foam. These materials, when combined with aluminum in a composite panel, can create a wall system that is both durable and energy-efficient.</p>

- Q: Is it possible to utilize aluminum strips in a construction project focused on sustainability and environmental responsibility?

- <p>Yes, you can use aluminum strips for a green building project. Aluminum is a versatile and sustainable material due to its recyclability and low energy consumption in production. It also has a high strength-to-weight ratio, which can contribute to the energy efficiency of a building. However, it's important to consider the source of the aluminum and ensure it is produced with minimal environmental impact. Using recycled aluminum can further enhance the green credentials of your project.</p>

- Q: The user is inquiring if it's possible to use recycled paints or coatings to prevent rust and corrosion on aluminum strips.

- <p>Yes, you can use recycled paints or coatings to protect aluminum strips from rusting or corrosion. However, it's important to ensure that the recycled paints are compatible with aluminum and offer sufficient protection. Recycled paints should be free from contaminants that could compromise the protective layer. Additionally, the application process should be done correctly to ensure an even and effective coating. It's also recommended to test a small area first to verify the effectiveness of the recycled paint or coating before applying it to the entire surface of the aluminum strips.</p>

- Q: Is it possible to use aluminum strips as a material for fencing?

- <p>Yes, you can use aluminum strips for fencing. Aluminum is a popular choice due to its durability, resistance to corrosion, and low maintenance requirements. It is lightweight, easy to install, and can be shaped into various designs. Aluminum fencing is also known for its strength and can be an effective barrier for security purposes. However, it may not be suitable for all environments, especially where high wind loads or heavy impacts are expected, as it can dent or bend more easily than some other materials.</p>

- Q: Is it possible to create a more energy-efficient roof using aluminum strips compared to other materials?

- <p>Yes, aluminum strips can be used to create a roof that is more energy-efficient than some other materials. Aluminum is a good conductor of heat, which can help in reflecting sunlight and reducing heat absorption, thus lowering cooling costs. Additionally, aluminum roofs can be designed with energy-efficient features such as solar reflectance and thermal emittance properties, which can further enhance their energy efficiency. However, it's important to consider the overall design, insulation, and installation quality to maximize energy efficiency.</p>

- Q: Can aluminum strips withstand harsh conditions like high humidity or salt spray?

- <p>Aluminum strips can be used in harsh environments to some extent, but their performance may be compromised. Aluminum is resistant to corrosion, making it suitable for high humidity conditions. However, in environments with significant salt spray exposure, aluminum can corrode over time, particularly due to the formation of galvanic cells when in contact with other metals. Protective coatings or anodizing can enhance its corrosion resistance, but it's not entirely impervious. Thus, while aluminum can be used in such environments, it requires proper protection and maintenance to ensure longevity.</p>

- Q: What effect does the aluminum pulley bring to the belt?

- The timing belt pulley is aluminum. Friction wheel? Not seen with aluminum, may be too hot, aluminum easy adhesion, resulting in increased friction

Send your message to us

Malleable Aluminum Strips - 1xxx Series Decorative Embossed Aluminum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 4999 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords