16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

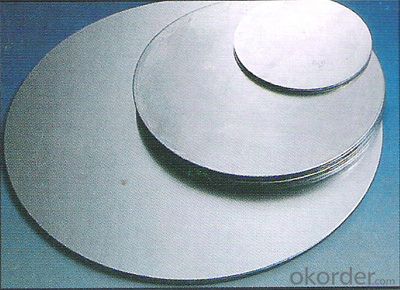

1.Structure of Re-Roling Aluminium Circle for Deep Drawing

Re-Roling Aluminium Circle for Deep Drawing is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Re-Roling Aluminium Circle for Deep Drawing

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| Alloy | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2MM-3MM | 1000MM-1800MM | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum sheets be used for electrical connectors?

- Aluminum sheets are indeed suitable for electrical connectors due to their high conductivity and excellent electrical properties. They are widely employed in various electrical applications, including connectors, thanks to their lightweight nature, durability, and cost-effectiveness compared to materials like copper. However, it is crucial to take into account specific factors such as the type and size of the connection, the amount of current to be transmitted, and the environmental conditions in which the connectors will be used. Furthermore, it is essential to implement proper insulation and protective measures to prevent corrosion, as aluminum is susceptible to oxidation. In summary, while aluminum sheets can be a viable option for electrical connectors, it is imperative to carefully assess individual requirements and conditions.

- Q: 1 ton of aluminium=______ tons of Alumina

- After analyzing the solutions I felt i'd desire to describe a sprint extra what others have not mentioned. constantly examine what the producer prints out on the label the two interior the door jam or glove container as to the finished available weight the truck can carry. Payload (weight it could carry) and towing potential (weight it could tow) are 2 a number of issues. additionally, maximum one ton vehicles can carry extra beneficial than a ton. as an occasion: If the vehicles GVWR gross motor vehicle weight score is 12000 lbs. and the truck weighs 7000 lbs, then you rather can haul 5000 lbs. this is human beings, gas, shipment, each thing. keep in mind, this is the optimal. GCWR Gross blended weight score is that of the truck and towing motor vehicle. If as an occasion this is 15000 lbs, and your truck weighs 7000lbs. then you rather are turning out to be an empty truck and tow as much as 8000 lbs. on the lighter edge, a million/2 ton %. united statesgeneraly are purely that--one thousand to 1900 lbs. 3/4 ton are a sprint extra and would have a camper kit as nicely. One plenty are stable for flatbeds, and the terminology is purely that--a generalization. stable success, and look for the placard.

- Q: What are the different surface finishes available for aluminum sheet?

- There are several different surface finishes available for aluminum sheet, each offering unique aesthetic and functional properties. Some of the common surface finishes for aluminum sheet include: 1. Mill Finish: This is the most basic and widely used surface finish for aluminum sheet. It has a smooth, raw appearance with visible grain lines from the manufacturing process. 2. Brushed Finish: This finish is achieved by brushing the aluminum sheet with a fine abrasive material, creating a pattern of fine lines. It provides a satin-like appearance and is often used for decorative purposes. 3. Anodized Finish: This finish is created through an electrochemical process called anodizing, which forms a durable oxide layer on the surface of the aluminum sheet. Anodized finishes are available in various colors and offer enhanced corrosion resistance. 4. Polished Finish: This finish involves polishing the aluminum sheet to a high gloss or mirror-like surface. It provides a reflective and elegant appearance, making it suitable for decorative applications. 5. Embossed Finish: This finish involves embossing patterns or textures onto the surface of the aluminum sheet. It adds texture and visual interest to the sheet, making it ideal for architectural and decorative purposes. 6. Powder Coated Finish: In this finish, a dry powder is applied to the surface of the aluminum sheet and then heated to form a protective and decorative coating. Powder coated finishes are available in a wide range of colors and offer excellent durability and resistance to weathering. These are just a few of the many surface finishes available for aluminum sheet. The choice of finish depends on the intended application, desired appearance, and specific performance requirements.

- Q: My frame snapped and I want to fix it by welding it back together. In order to do that, I need to know what all is in the aluminum.

- You can NOT weld back an aluminum frame unless you have the facilities to anneal and heat treat the frame again. Rewelding without the post treatments will result in a very soft area around the new weld causing sudden catastrophic failure... this means if you are riding it could fail at any time causing injury or death. EDIT: Wait just a durn minute. The 2100 and 2300 had carbon fiber tubes bonded to aluminum lugs and stays. If your bike failed then you ABSOLUTELY should not try to weld it. The heat from welding (even if you had post treatment facilities) would destroy the bond between the CF and aluminum. Fair warning- cut the frame apart and throw it away.

- Q: This question asks for an explanation of the various types of paint that can be applied to aluminum sheets.

- <p>Aluminum sheets can be coated with different types of paints to enhance their appearance, durability, and functionality. The common types include: 1) Acrylic Paints: Known for their flexibility and resistance to weathering and UV rays. 2) Polyester Paints: These offer excellent adhesion and gloss. 3) Epoxy Paints: Known for their chemical resistance and durability. 4) Polyurethane Paints: They provide a tough, scratch-resistant finish. 5) Powder Coatings: These are electrostatically applied and offer a durable, weather-resistant finish. 6) Fluoropolymer Coatings: They provide excellent resistance to chemicals and UV degradation. Each type has specific properties that make it suitable for different applications and environments.</p>

- Q: What type of aluminum plate does it contain?

- 1 * * * series aluminum sheet: stands for 1050, 1060, 1100. In all series, the 1 x x series belongs to a series with the largest amount of aluminum. Purity can reach more than 99%.2 * * * series aluminum sheet: 2A16 (LY16) and 2A06 (LY6). The characteristics of 2 * * * series of aluminum is high hardness, which belongs to the copper content is the highest, about 3-5%.

- Q: What will reflect light more- aluminum foil or white paper?

- aluminum foil reflects light more. you can almost see your reflection in foil while does not do that.

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

- Q: i added aluminum sulfate to the soil from the bag with out mixing it with water and my hydrangeas look very sad. It burned them i guess... What is best thing to do to take some of it out or all if i can? will adding large amounts of water to the soil help it clear or will it make it worse? please before they die!!!10points!!!

- Aluminum sulfate lowers the pH of soil (increases the acidity). To increase the pH, you need to add lime. The ideal pH for most plants is around neutrality, or pH = 7. I can't tell you how much lime to add, since I don't know how much aluminum sulfate you added. Try to add roughly the same amount as the aluminum sulfate and see if that helps. Overwatering may help some, as it will leach out some of the acid.

- Q: why does the bubble apear a few minutes later after putting aluminum sheet into diluted hydrochloric acid?

- Aluminum element is extremely activated and will react with oxygen, generating aluminum oxide, once being exposed in air, so there is a layer of aluminum oxide on the surface of daily aluminum products including aluminum sheet. When aluminum sheet is put into diluted hydrochloric acid, aluminum oxide on the surface will firstly react with hydrochloric acid, generating aluminium chloride and water, the process won’t generate bubble, but after finishing the reaction of aluminum oxide on the surface, when the exposed aluminum element reacts with hydrochloric acid, generating aluminium chloride and oxygen, the bubble appears.

Send your message to us

16 Gauge 4 X 8 Sheets of Aluminum - Re-Rolling Aluminum Circle for Deep Drawing

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords