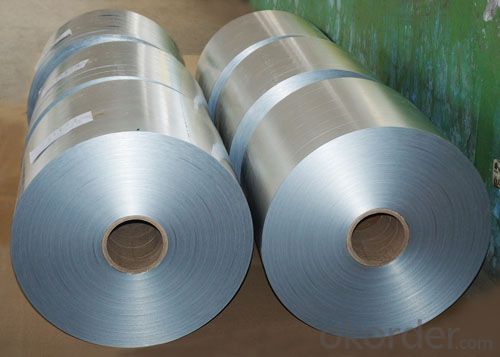

1235 Coated Aluminum Alloy Coil H24 Temper Aluminum Coil Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1235 Aluminum Alloy Coil H24 Temper Aluminum Coil

1050 1060 1070 1100 1235representative series aluminum plate is also known as pure aluminum, in the series in 1xxx series belongs to all the alumina quantity of a maximum number of series. Purity can achieve 99.00% above

3xxx series aluminum represents 3003 3004,3005, 3 A21 primarily. And can be called in the 3xxx series aluminum antirust aluminum production process more outstanding. The 3xxx series aluminum plate is by manganese as the main component. Content at 1.0-1.5 between. Is a rust-proof function better series. Conventional application in the air conditioning, the refrigerator, such as car in damp environment.

6xxx series represents 6061 mainly contain magnesium and silicon of two elements, so focused on the 4000 series and the advantages of the 5000 series 6061 is a cold treatment aluminum forging products, apply to fight against corrosion, oxidizing demanding applications.

Description

item | 1050 1060 1100 3003 Aluminum coil | |

Standard | GB/T3190-2008,GB/T3880-2006,ASTM B209,JIS H4000-2006,etc | |

Material | 1060,1050,1100 3003,3103,3004,3005,3105 5052, 5454,5754 | |

Size | Thickness | 0.5mm-3.5mm |

Width | 800-1500mm | |

Weight/Roll | About 1.5MT/3MT | |

Quality control | Mill Test Certificate is supplied with shipment, Third Part Inspection is acceptable. | |

Surface | Bright, polished, hair line, brush, checkered, embossed, etc | |

Trade terms | Price term | ,FOB, CNF, CIF, etc |

Payment Term | TT,L/C | |

MOQ | 2MT | |

20 GP Capacity | About 20-25MT | |

Delivery time | 1.The products will delivery immediately after receiving the payment. 2.According to the order quantity, prompt delivery. | |

Export to | Ireland,Singapore,Indonesia,Ukraine,Spain,Canada,USA,Brazil,Thailand,Korea,Iran,India,Egypt,Kuwait, Oman,Viet Nam, South Africa, Dubai, Russia, etc | |

Package | Stick blue film→plastic film→waterproof paper→1~2 tons on a export standard pallet(corner protection) | |

Application | 1)Further making utensil.2)Solar reflective film3)The appearance of the building4)Interior decorating:ceilings,walls,etc.5)Furniture cabinets6)Elevator decoraction7)Signs,nameplate,bags making.8)Decoration inside and outside the car9)Household appliances:refrigerators,microwave ovens,audio equipment,etc.10)The consumer electronics:mobile phones,digital cameras,MP3,etc. | |

- Q: How do aluminum coils compare to other types of coils (e.g., copper)?

- The usage of aluminum coils and copper coils is prevalent in multiple industries. While each type has its own pros and cons, it is crucial to understand their relative comparisons. An important distinction between aluminum and copper coils is their conductivity. Copper is renowned for its exceptional electrical and thermal conductivity, making it the preferred choice for applications that necessitate efficient heat transfer. Conversely, aluminum possesses lower conductivity than copper, yet it still conducts electricity and heat effectively. Another factor to consider is cost. Copper is more expensive than aluminum due to its higher demand and limited availability. Consequently, aluminum coils are often chosen as a cost-effective alternative, particularly in applications where the high conductivity of copper is not necessary. In terms of weight, aluminum coils are significantly lighter than copper coils. This attribute facilitates easier handling and installation, leading to reduced transportation and labor costs. The lightweight nature of aluminum coils also renders them suitable for weight-sensitive applications, such as automotive and aerospace industries. In terms of corrosion resistance, copper coils outperform aluminum coils. Copper exhibits high resistance to corrosion, ensuring a longer lifespan and reduced maintenance requirements. Conversely, aluminum is more prone to corrosion, especially in environments with high humidity or exposure to specific chemicals. However, through proper coatings and treatments, aluminum coils can be effectively protected against corrosion. Durability is another crucial aspect to consider. Copper coils are known for their durability and ability to withstand extreme conditions, making them suitable for applications requiring longevity. While aluminum coils may not be as durable as copper, they can still offer satisfactory performance in many applications, particularly when designed and maintained appropriately. In conclusion, aluminum coils and copper coils possess distinct characteristics and advantages. Copper coils offer superior conductivity, corrosion resistance, and durability, albeit at a higher cost. On the other hand, aluminum coils are lighter, more cost-effective, and suitable for various applications. Ultimately, the choice between the two types of coils depends on specific requirements, budget constraints, and environmental factors of the given application.

- Q: Can aluminum coils be customized in terms of thickness?

- Yes, aluminum coils can be customized in terms of thickness. The thickness of aluminum coils can be modified through various manufacturing processes to meet specific requirements and applications.

- Q: What are the different forming processes for aluminum coils?

- Aluminum coils can be formed using various methods. These methods include: 1. The most commonly employed technique for forming aluminum coils is hot rolling. It requires heating the aluminum to a high temperature and then passing it between two large rolls to decrease its thickness. This process enables precise control over the coil's thickness and shape. 2. Cold rolling, a similar process to hot rolling, involves cooling the aluminum to room temperature before rolling it. Cold rolling is often preferred for producing coils with a smoother surface finish and stricter tolerances. 3. Continuous casting involves pouring molten aluminum into a continuous casting machine, which generates an uninterrupted strip of aluminum. The strip is then cooled and coiled to form aluminum coils. Continuous casting is commonly used for large-scale production. 4. Extrusion is a process that entails pushing aluminum through a die to create a particular shape or profile. The extruded aluminum is subsequently cooled and coiled to produce aluminum coils. Extrusion is frequently employed to manufacture coils with intricate shapes or profiles. 5. Slitting is a process used to cut aluminum coils into narrower strips. It involves passing the coil through a set of rotating blades that slice it into multiple smaller strips. Slitting is often utilized to produce coils with specific widths or for further processing. These are just a few examples of the various forming processes available for producing aluminum coils. The selection of a process depends on factors such as the desired shape, thickness, and surface finish of the coil, as well as considerations of production volume and cost.

- Q: What is the composition of aluminum coils?

- Aluminum coils are typically composed of pure aluminum or an aluminum alloy. Pure aluminum coils consist of 99.5% aluminum, with trace amounts of other elements. Aluminum alloys, on the other hand, are made by combining aluminum with other metals such as copper, magnesium, manganese, or zinc. These alloys are specifically designed to enhance the strength, corrosion resistance, and other desired properties of the aluminum coils. The exact composition of aluminum coils may vary depending on the specific application and requirements, but they generally contain a high percentage of aluminum along with small quantities of other elements to create a more durable and efficient product.

- Q: Can aluminum coils be used for HVAC systems?

- Yes, aluminum coils can be used for HVAC systems. Aluminum coils are commonly used in HVAC systems as they offer several advantages over other coil materials. Firstly, aluminum is a lightweight material, which makes it easier to handle and install. This can result in lower installation costs and reduced strain on the structure of the HVAC system. Secondly, aluminum coils have excellent heat transfer properties. They efficiently transfer heat from the refrigerant to the surrounding air, which is crucial for the effective functioning of the HVAC system. Aluminum coils also have a high resistance to corrosion, which is particularly important in humid environments or areas with high levels of pollutants. Additionally, aluminum is a highly recyclable material, making it an environmentally friendly choice for HVAC systems. It can be easily recycled and reused, reducing the need for new material extraction and minimizing waste. Overall, aluminum coils are a reliable and efficient choice for HVAC systems, providing excellent heat transfer, durability, and environmental sustainability.

- Q: Can aluminum coils be used in the production of aluminum louvers?

- Aluminum coils have the capability to be utilized in the manufacturing of aluminum louvers. These coils are a prevalent raw material in various industries, including the louver production sector. In order to meet the necessary strength and durability criteria, the aluminum coils undergo processing and shaping to match the required design for the louvers. This process also permits the customization and flexibility of louvers to meet specific demands. Moreover, aluminum, being a lightweight and corrosion-resistant material, is ideal for louvers that are exposed to outdoor conditions. Consequently, due to their multitude of benefits and suitability for this purpose, aluminum coils are extensively employed in the production of aluminum louvers.

- Q: I HEARD THAT ALUMINUM POWDER TIGHTEN YOUR VAGINA BUT WHERE DO I BUY IT AND HAVE ANY ONE HEARD OF BEYDARY PILLS, I HEARD THEY TIGHTEN YOUR VAGINA ALSO AND WHERE CAN I BUY THEM

- try leaving it alone for awhile

- Q: Can aluminum coils be used in food packaging?

- Yes, aluminum coils can be used in food packaging. Aluminum is a popular choice for food packaging due to its excellent barrier properties, lightweight nature, and ability to maintain the freshness and quality of food products. It is widely used in various forms, including coils, for packaging food items like beverages, snacks, and canned goods.

- Q: Are aluminum coils suitable for interior design applications?

- Aluminum coils are indeed a fitting choice for interior design purposes. The versatility of aluminum as a material presents a multitude of advantages for interior design endeavors. To begin with, aluminum possesses a lightweight nature, ensuring ease of handling and installation. This quality proves particularly advantageous for projects necessitating extensive installations or suspended ceilings. Moreover, aluminum coils exhibit exceptional durability and corrosion resistance, guaranteeing extended lifespan and suitability for high-traffic regions. Furthermore, aluminum can be effortlessly tailored and molded to meet specific design requirements, thereby offering limitless design possibilities. Additionally, the material is available in a plethora of finishes, including brushed, polished, or anodized options, which can significantly enhance the aesthetic allure of any interior space. Furthermore, aluminum emerges as a sustainable and eco-friendly alternative, given its easy recyclability and low carbon footprint relative to other materials. All in all, aluminum coils represent a pragmatic and visually pleasing choice for interior design applications.

- Q: Can aluminum coils be used in the production of electrical transformers?

- Yes, aluminum coils can be used in the production of electrical transformers. Aluminum is a lightweight and cost-effective material that offers many advantages in transformer manufacturing. While copper has traditionally been the preferred choice for transformer windings, aluminum is becoming increasingly popular due to its lower cost and weight. Aluminum coils have good electrical conductivity and high thermal conductivity, which are essential for efficient transformer operation. Moreover, aluminum coils are easier to handle and install due to their lighter weight. However, it is important to note that aluminum coils require larger cross-sectional areas compared to copper coils to achieve the same electrical conductivity. Additionally, aluminum coils may require additional measures to mitigate the effects of aluminum's higher coefficient of expansion, such as using proper insulation and mechanical support. Overall, aluminum coils can indeed be used in the production of electrical transformers, offering a viable alternative to copper coils in certain applications.

Send your message to us

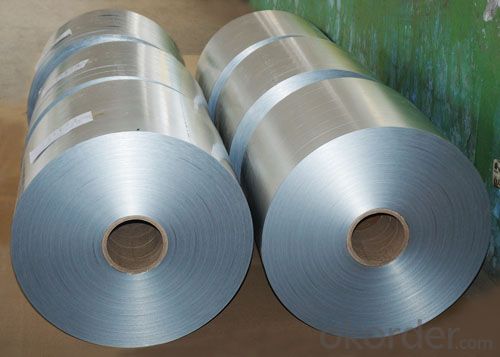

1235 Coated Aluminum Alloy Coil H24 Temper Aluminum Coil Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 6000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords