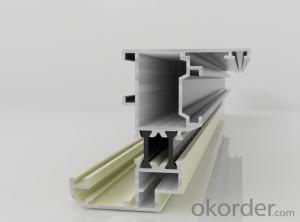

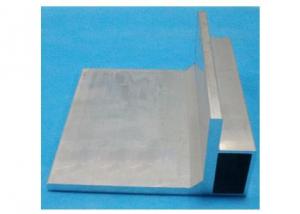

10mm Anodized Bronze Color Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: Is it possible to recycle aluminum profiles and what are the benefits of doing so?

- <p>Yes, aluminum profiles can be recycled. Recycling aluminum is energy-efficient, as it requires only 5% of the energy needed to produce new aluminum from raw materials. This process reduces greenhouse gas emissions and conserves natural resources. Recycled aluminum maintains its quality, making it suitable for various applications, including construction, automotive, and consumer goods. Proper recycling also helps to reduce landfill waste and promotes a circular economy.</p>

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Domestic aluminum quality is about the same, mainly you installed in the window accessories, is the key to the life of the service, recommend several brands Bar Reid Jan Ron Lixin spring is not recommended, quality is not very rely on live

- Q: This question asks for an explanation of the manufacturing process of aluminum profiles.

- <p>Aluminum profiles are made through a series of processes starting with the selection of high-quality aluminum ingots. These ingots are melted in a furnace and then extruded through a die to create the desired profile shape. The extrusion process involves forcing the molten aluminum through a shaped opening in the die, which gives the aluminum its final form. After extrusion, the profiles are cooled, straightened, and cut to length. They may then undergo secondary processes such as anodizing, powder coating, or painting for enhanced durability and appearance. Finally, the profiles are inspected for quality and packed for distribution.</p>

- Q: Is it possible to recycle aluminum profiles and repurpose them for different uses?

- <p>Yes, aluminum profiles can be recycled and reused in other applications. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing aluminum from raw materials. Recycled aluminum maintains its properties, making it suitable for a variety of new applications, such as construction, automotive, and consumer goods. The recycling of aluminum profiles not only conserves resources but also reduces waste and environmental impact.</p>

- Q: Are there any specific cleaning and maintenance instructions for aluminum profiles?

- Yes, there are specific cleaning and maintenance instructions for aluminum profiles. Here are a few guidelines to follow: 1. Regular cleaning: Aluminum profiles should be regularly cleaned to maintain their appearance and prevent corrosion. Use a mild soap or detergent mixed with water to clean the surface. Avoid using abrasive cleaners or steel wool as they can scratch the aluminum. 2. Avoid harsh chemicals: Harsh chemicals can damage the protective coating on the aluminum profiles. Avoid using strong acids, alkaline cleaners, or solvents for cleaning purposes. 3. Rinse thoroughly: After cleaning, make sure to rinse the aluminum profiles thoroughly with clean water. This will remove any residue from the cleaning solution and prevent streaking. 4. Dry thoroughly: After rinsing, dry the aluminum profiles completely using a soft cloth or towel. Moisture left on the surface can lead to corrosion, so it's important to ensure the profiles are completely dry. 5. Lubrication: If the aluminum profiles have moving parts or hinges, it's recommended to lubricate them regularly to ensure smooth operation. Use a lubricant specifically designed for aluminum to avoid any adverse effects. 6. Protective coatings: Some aluminum profiles come with protective coatings, such as anodized or powder-coated finishes. These coatings provide an extra layer of protection against corrosion and should be maintained as per the manufacturer's instructions. 7. Avoid abrasive cleaning tools: When cleaning aluminum profiles, avoid using abrasive cleaning tools such as brushes or scouring pads. These can scratch the surface and damage the protective coating. It's important to note that specific cleaning and maintenance instructions may vary depending on the type and finish of the aluminum profiles. Therefore, it's always advisable to refer to the manufacturer's guidelines for the best cleaning and maintenance practices for your specific aluminum profiles.

- Q: What are the water-resistant properties of aluminum profiles?

- Because of their natural oxide layer, aluminum profiles have excellent water-resistant properties. This layer acts as a protective barrier, preventing water molecules from penetrating and stopping corrosion. Furthermore, various surface treatments like anodizing, powder coating, or painting can enhance aluminum profiles even more, providing an extra layer of defense against water damage. These treatments not only improve the profiles' appearance but also increase their resistance to water, making them suitable for outdoor use or in areas with high humidity. Additionally, aluminum profiles are inherently structurally sound and dimensionally stable, even in wet environments. This makes them a dependable choice for water-resistant applications such as windows, doors, and façade systems.

- Q: This question asks for an explanation of the various types of aluminum profiles that are specifically used in the manufacturing and construction of windows and doors.

- <p>Aluminum profiles for windows and doors come in various types, each serving specific functions and designs. Common types include: 1) Casement profiles, used for side frames and meeting stiles in casement windows; 2) Mullion profiles, for vertical and horizontal structural members in window walls; 3) Transom profiles, used in the top or bottom of windows to support glazing; 4) Sash profiles, forming the main frame of the window sash; 5) Threshold profiles, used at the bottom of doors for weather sealing; 6) Header profiles, supporting the top of a door or window opening; and 7) Specialty profiles, designed for specific architectural needs like corner posts or decorative elements. Each profile is engineered for strength, durability, and compatibility with glazing and浜旈噾閰嶄欢.</p>

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

- Q: What are the different surface finishing options available for aluminum profiles?

- There are several surface finishing options available for aluminum profiles, each offering different benefits and aesthetic appearances. Some of the commonly used surface finishing options for aluminum profiles include: 1. Anodizing: Anodizing is an electrochemical process that creates a protective oxide layer on the surface of the aluminum. This process not only enhances corrosion resistance but also provides a variety of color options. Anodized aluminum profiles are durable, easy to maintain, and have a smooth, attractive finish. 2. Powder Coating: Powder coating involves applying a dry powder to the surface of the aluminum profile and then curing it under heat. This process creates a tough, decorative finish that is resistant to chipping, scratching, and fading. Powder coating offers a wide range of color options and can be customized to achieve different textures and effects. 3. Polishing: Polishing is a mechanical process that creates a high-gloss, reflective finish on the aluminum profile. It involves using abrasives and polishing compounds to remove surface imperfections and achieve a smooth, mirror-like appearance. Polished aluminum profiles are commonly used in decorative applications where a sleek and shiny finish is desired. 4. Brushing: Brushing involves using abrasive brushes or pads to create a textured, brushed finish on the aluminum profile. This process produces parallel lines or circular patterns on the surface, giving it a unique and stylish appearance. Brushed aluminum profiles are often used in architectural and interior design applications. 5. Electrophoretic Coating: Electrophoretic coating, also known as e-coating, is an immersion process where an electrically charged paint is applied to the aluminum profile. This process ensures uniform coating thickness and excellent corrosion resistance. E-coating provides a smooth, even finish and is commonly used in automotive and industrial applications. 6. Wood Grain Effect: Aluminum profiles can be treated with a special coating to mimic the appearance of wood grain. This option is popular in architectural applications where the durability and low maintenance of aluminum are preferred over natural wood. These are just a few of the surface finishing options available for aluminum profiles. The choice of finishing method depends on the desired appearance, functionality, and intended application of the aluminum profile.

- Q: Can aluminum profiles be used for stage and truss structures?

- Yes, aluminum profiles can be used for stage and truss structures. Aluminum is a lightweight, durable, and versatile material that is commonly used in construction and engineering applications, including stage and truss structures. It offers excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication, making it an ideal choice for such purposes.

Send your message to us

10mm Anodized Bronze Color Aluminum Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords