ASTM 1080 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 1080 Carbon Steel Round Bars

Products Details

1.Characteristics

1) Even material.

2) Good machinability and polishability.

3) High toughness and high plasticity.

4) High abrasive resistance in high temperature.

5) Excellent total hardenability.

6) Low deformability during heat treatment.

7) Better isotropy.

2.Application

1) Diecasting mould(mold, fixed block, upper die, jet nozzle, nitride thimble ).

2) Extrusion die(mold, supporting member, choke blocks).

3) Hot press die. (aluminum, magnesium, copper alloy)

4) Parts, such as cold cutting, overlap, hot shears, wearable parts.

5) Important parts for aviation industry.

We can produce one hundred kinds of products, including cold work tool steel, hot work tool steel, plastic mould steel and many other alloy tool steel. We are mainly supplying tool steels as below aboard:

AISI: D2, D3, D6, D7, A2, A6, A8, A10, H10, H11, H13, H21, S1, S5, S7, O1, O6;

DIN: 1.2080, 1.2316, 1.2343, 1.2344, 1.2379, 1.2510, 1.2601, 1.2713, 1.2714, 1.2767, 1.2842;

JIS: SKD1, SKD11, SKD61, DC53;

GB: Cr12, Cr12MoV, Cr12Mo1V1, 6CrW2Si, 4Cr5MoSiV, 4Cr5MoSiV1, 3Cr2W8V.

3. Chemical composition of steel bar

| Standard | C | Si | Mn | Cr | Ni | P/S ≤ |

| DIN | ≤0.15 | ≤1.0 | ≤2.0 | 18 | 9 | 0.03 |

| GB | ≤0.15 | ≤1.0 | ≤2.0 | 18 | 9 | 0.03 |

4.Material and Grade

| Material | Grade | Material | Grade |

| 8#-10# | φ16-290 | 65Mn | φ40-300 |

| 15# | φ14-150 | 45Mn2 | φ18-75 |

| 20# | φ8-480 | 60Si2Mn | φ16-150 |

| 35# | φ8-480 | 20CrMnTi | φ10-480 |

| 45# | φ6.5-480 | 20CrMnTiB | φ16-75 |

| Q235B | φ6.5-180 | GCr15 | φ16-400 |

| 40Cr | φ8-480 | ML35 | φ8-150 |

| 20Cr | φ10-480 | T8-T13 | φ8-480 |

| 42CrMo | φ12-480 | Cr12 | φ16-300 |

| 35CrMo | φ12-480 | Cr12MoV | φ16-300 |

| 20CrMo | φ12-300 | 3Cr2W8V | φ16-300 |

| 38CrMoAL | φ20-300 | 45Cr50Cr | φ20-300 |

| 5CrMnMo | φ20-450 | 20CrMnMo | φ20-300 |

| 16Mn(Q345B) | φ14-365 | 40Mn2 | φ28-60 |

| 50Mn | φ40-200 | 35Cr | φ55 |

| 15CrMo | φ21 φ24 φ75 | 15Mn | φ32φ170 |

| 25# | φ16-280 | 40CrMnMo | φ80φ160 |

| YF45MnV | φ28-80 | 20CrMnMo | φ20-300 |

| 30# | φ6.5-480 | 27SiMn | φ20-350 |

| 30CrMo | φ28 | Crwmn | φ20-300 |

| 30CrMnTi | φ16-300 | H13(4Cr5MoSiVi) | φ20-300 |

| 60# | φ210 φ260 | 40CrNiMo | φ20-400 |

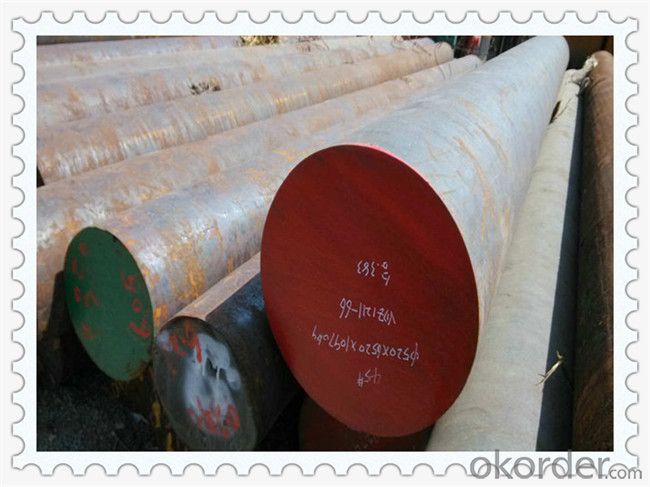

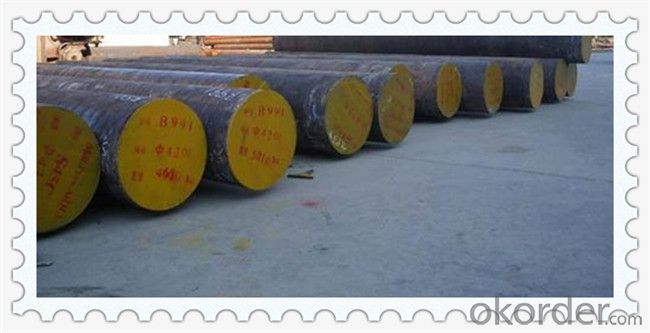

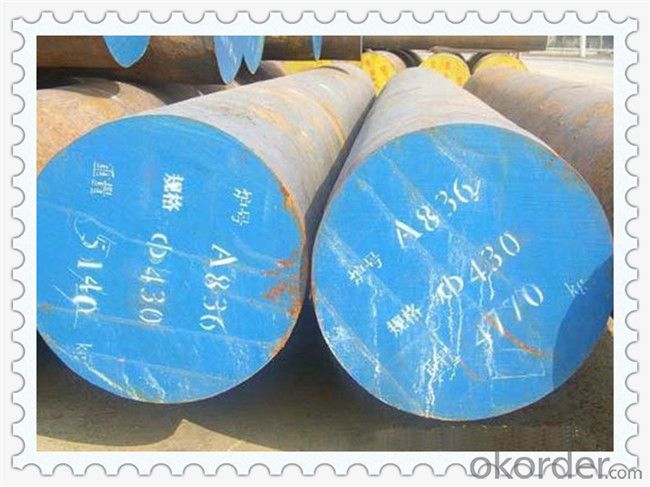

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and

logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: How do you determine the hardness of a steel round bar?

- There are various methods available to determine the hardness of a steel round bar. One commonly used method is the Rockwell hardness test, where a minor load is applied to the bar's surface using a diamond or hardened steel ball, followed by a major load. The depths of penetration for both loads are measured, and the hardness value is determined based on the difference between these depths. Another method is the Brinell hardness test, which involves indenting the steel bar's surface using a hardened steel ball under a specific load. The resulting indentation's diameter is measured, and the hardness value is calculated based on the load and indentation diameter. Alternatively, the Vickers hardness test can also be utilized. This test employs a diamond pyramid-shaped indenter applied to the steel bar's surface under a specific load. The size of the indentation is measured, and the hardness value is determined based on the load and indentation's surface area. It's important to consider that the choice of method depends on factors such as the steel type and desired accuracy of the measurement. Moreover, other factors like heat treatment and composition can impact the steel bar's hardness, so they should be taken into account during hardness determination.

- Q: What are the advantages of using bearing steel round bars?

- There are several advantages of using bearing steel round bars: 1. High strength and durability: Bearing steel round bars are known for their exceptional strength and durability. They are specifically designed to withstand heavy loads and high impact forces, making them ideal for applications that require a reliable and robust material. 2. Excellent wear resistance: Bearing steel round bars have excellent wear resistance properties, which means they can endure constant friction and abrasion without experiencing excessive wear and tear. This makes them suitable for applications where the material needs to withstand repetitive rotational motion or sliding. 3. Superior hardness: Bearing steel round bars are typically heat-treated to achieve optimal hardness levels. This hardness allows them to maintain their shape and structural integrity even under extreme conditions, such as high temperatures or heavy loads. 4. Dimensional stability: Bearing steel round bars exhibit excellent dimensional stability, meaning they maintain their shape and size even under varying temperature and environmental conditions. This quality is crucial in applications where precise dimensions are required to ensure proper functioning and performance. 5. Corrosion resistance: Bearing steel round bars are often alloyed with elements like chromium and molybdenum, which enhance their corrosion resistance. This makes them suitable for use in corrosive environments, such as marine or chemical industries. 6. Machinability: Bearing steel round bars are relatively easy to machine and process, which allows for efficient production and customization. This makes them a cost-effective choice for various applications, as they can be easily shaped, cut, or drilled according to specific requirements. Overall, the advantages of using bearing steel round bars include their high strength, excellent wear resistance, superior hardness, dimensional stability, corrosion resistance, and machinability. These qualities make them a preferred choice in industries such as automotive, aerospace, machinery, and construction, where reliability, durability, and performance are crucial.

- Q: Can steel round bars be used for making conveyor belts or rollers?

- No, steel round bars are not typically used for making conveyor belts or rollers. Conveyor belts and rollers are usually made from materials such as rubber, polyurethane, or other flexible and durable materials that can withstand the constant movement and friction involved in conveying items.

- Q: What is the difference between a polished and a precision ground steel round bar?

- A polished steel round bar refers to a bar that has undergone a polishing process to achieve a smooth and shiny surface finish. This process involves using abrasive materials to remove any imperfections or roughness on the surface of the bar. The end result is a visually appealing bar with a high level of aesthetic appeal. On the other hand, a precision ground steel round bar is a bar that has been precisely ground to achieve tight dimensional tolerances and a smooth surface finish. This grinding process involves removing material from the surface of the bar using grinding wheels or other cutting tools. The purpose of precision grinding is to ensure that the bar meets specific size and shape requirements, making it suitable for use in applications that demand precise dimensions and tight tolerances. In summary, the main difference between a polished and a precision ground steel round bar lies in the purpose of the respective finishing processes. Polishing is primarily done for aesthetic reasons, enhancing the appearance of the bar, while precision grinding focuses on achieving precise dimensions and tight tolerances to meet specific technical requirements.

- Q: Which is stronger, steel pipe or round steel? Which is good at bending?

- Of resistance to shearing, of course, of high round steel, generally used with steel tubes (light weight and material saving) for transmitting torque

- Q: What are the different types of steel round bar alloys for improved machinability?

- There are several types of steel round bar alloys that are specifically designed to improve machinability. These alloys are chosen for their ability to be easily shaped, cut, and drilled, which is crucial in various machining applications. Some of the commonly used steel round bar alloys for improved machinability include: 1. 12L14 Steel: This alloy contains added lead, which enhances its machinability. The presence of lead lubricates the cutting tool, reduces friction, and improves chip formation during the machining process. 2. 1215 Steel: Similar to 12L14, 1215 steel also contains added lead, which provides excellent machinability. This alloy is known for its high cutting speeds, smooth surface finish, and improved chip control. 3. 4140 Steel: Although not specifically designed for machinability, 4140 steel is known for its excellent overall machining properties. With proper heat treatment, this alloy offers good strength, toughness, and wear resistance while still maintaining a reasonable level of machinability. 4. 1018 Steel: This low carbon steel alloy is widely used for its excellent machinability. It is easy to cut, drill, and shape, making it suitable for a variety of machining operations. However, it may have lower strength compared to some other alloys. 5. 8620 Steel: This alloy is specifically designed for case hardening, but it also offers good machinability. 8620 steel can be easily machined, providing high surface finish and dimensional accuracy. 6. 416 Stainless Steel: This stainless steel alloy provides good machinability due to its sulfur content. It is used in applications where corrosion resistance is required along with improved machinability. These are just a few examples of steel round bar alloys that are chosen for their enhanced machinability. The selection of the appropriate alloy depends on the specific machining requirements and the desired properties in the final product.

- Q: Can steel round bars be coated with protective coatings?

- Yes, steel round bars can be coated with protective coatings. These coatings serve as a barrier to protect the steel from corrosion, abrasion, and other forms of damage. The most common type of protective coating used on steel round bars is called a corrosion-resistant coating. This coating is typically applied through processes such as hot-dip galvanizing, electroplating, or powder coating. These coatings provide a layer of protection that prevents the steel from coming into contact with corrosive substances, moisture, and other environmental factors that may cause deterioration. Additionally, protective coatings can also enhance the appearance of the steel round bars and increase their lifespan.

- Q: What is the difference between a turned and a polished steel round bar?

- A turned steel round bar and a polished steel round bar both undergo separate processes that result in different surface finishes and properties. A turned steel round bar is typically created by using a lathe machine to remove material from the surface of a steel bar. This process involves rotating the bar against a cutting tool, which cuts away the outer layer and leaves behind a smooth and cylindrical surface. The turned bar may have visible machining marks due to the cutting process, although it is generally considered to have a more precise and uniform diameter compared to other types of steel bars. Turned bars are often used in applications where dimensional accuracy is crucial, such as in machinery or tooling. On the other hand, a polished steel round bar undergoes a different process that involves grinding or buffing the surface to achieve a smooth and reflective finish. Polishing removes any imperfections or roughness from the surface of the steel bar, resulting in a highly lustrous appearance. Polished bars are often used in decorative applications or where visual aesthetics are important, such as in architectural designs or high-end consumer products. In summary, the main difference between a turned and a polished steel round bar lies in their respective manufacturing processes and resulting surface finishes. A turned bar is machined to achieve precise dimensions, while a polished bar is subjected to a polishing process to obtain a smooth and reflective surface. The choice between the two depends on the specific requirements of the application, with turned bars being preferred for dimensional accuracy and polished bars for aesthetic appeal.

- Q: What are the different types of steel used in manufacturing round bars?

- There are several different types of steel that are commonly used in the manufacturing of round bars. Some of the most common types include: 1. Carbon Steel: This is the most common type of steel used in manufacturing round bars. It is made up primarily of iron and carbon, and is known for its strength and durability. Carbon steel round bars are used in a wide range of applications, including construction, automotive, and machinery. 2. Alloy Steel: Alloy steel is made by adding various elements to carbon steel, such as manganese, nickel, chromium, and molybdenum. These additional elements enhance the strength and hardness of the steel, making it ideal for applications that require high strength and resistance to wear and tear. 3. Stainless Steel: Stainless steel is a type of alloy steel that contains a minimum of 10.5% chromium. This high chromium content gives stainless steel its unique corrosion resistance properties, making it suitable for applications where exposure to moisture or chemicals is a concern. Stainless steel round bars are commonly used in the manufacturing of kitchen utensils, medical equipment, and automotive parts. 4. Tool Steel: Tool steel is a type of alloy steel that is specifically designed to have high hardness, wear resistance, and heat resistance. It is commonly used in the manufacturing of cutting tools, dies, and molds. Tool steel round bars are typically made from high-carbon steel with additional elements like tungsten, vanadium, or cobalt. 5. Bearing Steel: Bearing steel is a type of alloy steel that is specifically designed for use in bearing applications. It is characterized by its high hardness, wear resistance, and fatigue strength. Bearing steel round bars are commonly used in the manufacturing of bearings for various industries, including automotive, aerospace, and industrial machinery. These are just a few examples of the different types of steel used in the manufacturing of round bars. The specific type of steel chosen will depend on the desired properties and requirements of the application.

- Q: Can steel round bars be used for making bicycle frames or handlebars?

- Yes, steel round bars can be used for making bicycle frames or handlebars. Steel is a commonly used material in bicycle manufacturing due to its strength, durability, and affordability. Round bars made of steel provide excellent rigidity and stability, which are essential for ensuring the structural integrity of a bicycle frame or handlebars. Additionally, steel has a high tensile strength, allowing it to withstand the stresses and strains experienced during cycling. It is worth noting that different types of steel, such as chromoly steel, may be preferred for bicycle frames and handlebars as they offer specific advantages such as improved strength-to-weight ratio. However, in general, steel round bars are a suitable choice for constructing bicycle frames and handlebars.

Send your message to us

ASTM 1080 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords