PVDF Coated 1060-H14 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc.

There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5000 series, 6000series, etc. The detailed grade are as follows: 1010, 1050,1060,1100, 2024, 3003, 3005, 3105, 5052,5754,5083,6061,6063,8011, etc.

The temper is include H14, H22, H24, H44,H112,H114,etc.

2. Main features of the product

a.Competitive price

b.Frist-Class Service.

c. Shortest service.

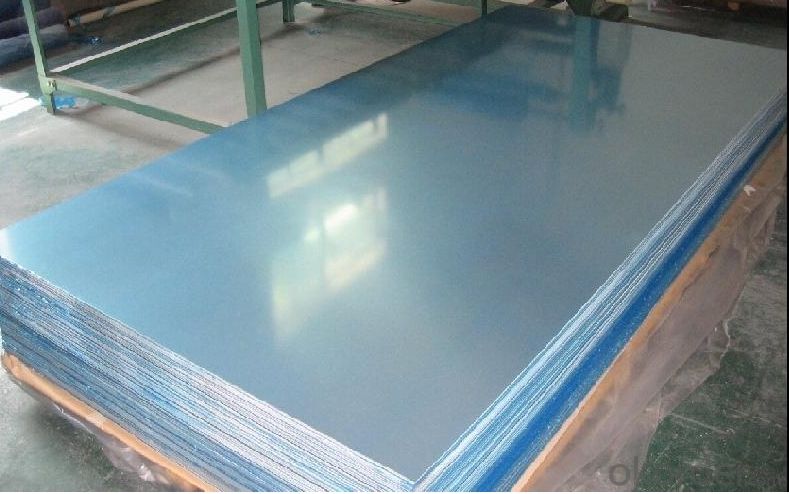

3. Image

4. Product detailed sizes:

1000mm*2000mm, 1219mm*2438mm,1220mm*2440mm, 1250mm*2500mm,1500mm*3000mm, etc.

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

What is the length range:

---It is from 2000mm to 6000mm, etc.

- Q: What are the advantages of using aluminum sheets compared to other materials?

- There are several advantages of using aluminum sheets compared to other materials. Firstly, aluminum sheets are lightweight, which makes them easy to transport and handle. This characteristic also makes them ideal for applications where weight reduction is crucial, such as in aerospace, automotive, and marine industries. Secondly, aluminum sheets have excellent corrosion resistance. They naturally form a protective oxide layer on their surface, which prevents further oxidation and corrosion. This property makes them suitable for outdoor applications, as they can withstand various weather conditions without deteriorating. Thirdly, aluminum sheets have high thermal conductivity. This means they can efficiently transfer heat, making them ideal for heat exchangers and other applications that require efficient heat dissipation. Moreover, aluminum sheets have excellent formability. They can be easily fabricated into different shapes and sizes, making them versatile for various industries. This formability also allows for complex designs and intricate details to be achieved. Furthermore, aluminum sheets have good electrical conductivity. This makes them suitable for electrical applications, such as wiring and electrical conductors. Another advantage of aluminum sheets is their recyclability. Aluminum is one of the most sustainable metals, as it can be recycled repeatedly without losing its quality or properties. This makes aluminum sheets an environmentally friendly choice. Lastly, aluminum sheets are cost-effective. Compared to other materials, aluminum is relatively affordable, making it a popular choice for many industries. In conclusion, the advantages of using aluminum sheets include their lightweight nature, excellent corrosion resistance, high thermal conductivity, good formability, electrical conductivity, recyclability, and cost-effectiveness. These properties make aluminum sheets a versatile and sustainable material for a wide range of applications.

- Q: Is it possible to use aluminum sheets as a material for exterior walls in regions with cold climates?

- <p>Yes, aluminum sheets can be used for exterior walls in cold climates. Aluminum is a durable and lightweight material with good thermal conductivity, which can be beneficial for heat transfer. However, it's crucial to use insulated aluminum panels or combine aluminum with insulation materials to prevent heat loss and maintain indoor comfort. Proper design and installation are essential to ensure the building envelope's thermal performance and structural integrity in cold weather conditions.</p>

- Q: Can aluminum sheets be used in food packaging?

- Indeed, aluminum sheets find widespread application in the realm of food packaging. The utilization of aluminum in this context is prevalent owing to its exceptional capability to shield food from detrimental elements like light, oxygen, moisture, and other external agents that may cause spoilage or contamination. Notably, aluminum sheets possess the qualities of being lightweight, long-lasting, and resistant to corrosion, rendering them perfectly suitable for an array of food packaging formats, including foil wraps, containers, trays, and pouches. Moreover, the recyclability of aluminum further solidifies its status as an eco-friendly option for food packaging.

- Q: Can aluminum be either conductive or magnitized?

- Aluminum is conductive. In fact at one point in time it was used as an alternative to copper wiring for home electrical wiring. (There were problems, so it is no longer used).

- Q: How is the thickness of an aluminum sheet measured?

- The thickness of an aluminum sheet is typically measured using a tool called a micrometer. This handheld device applies pressure to the sheet and displays the measurement in millimeters or inches on a digital or analog gauge.

- Q: This question asks for a guide on the correct procedure to install aluminum sheets, likely for construction or renovation purposes.

- <p>To install aluminum sheets properly, follow these steps: 1. Prepare the surface by cleaning and leveling it. 2. Measure and cut the aluminum sheets to the required size using a metal saw or tin snips. 3. Apply a bead of construction adhesive along the edges of the surface where the sheets will be placed. 4. Position the aluminum sheet, ensuring it's aligned correctly. 5. Secure the sheet with screws or nails, using a washer to prevent tearing. 6. Seal the seams and edges with a weatherproof sealant to prevent water ingress. 7. Inspect the installation for any gaps or unevenness and make adjustments as needed. Always follow the manufacturer's guidelines and safety precautions while working with aluminum sheets.</p>

- Q: Are the aluminum sheets suitable for manufacturing solar reflectors?

- Aluminum sheets, indeed, prove to be fitting for the production of solar reflectors. As a material, aluminum possesses high reflectivity, enabling it to efficiently bounce off sunlight, thereby making it an optimal selection for solar reflectors. Its remarkable reflectivity and minimal heat absorption, owing to its low emissivity, allow it to effectively deflect a substantial amount of solar radiation. Moreover, aluminum exhibits qualities of being lightweight, long-lasting, and resistant to corrosion, rendering it appropriate for outdoor usage. Furthermore, its malleability permits simple shaping and molding into diverse reflector designs. All in all, aluminum sheets offer exceptional performance and dependability when it comes to constructing solar reflectors in solar energy systems.

- Q: Can aluminum sheets be painted?

- Yes, aluminum sheets can be painted. However, it is important to properly prepare the surface by cleaning, sanding, and using a primer specifically formulated for metal surfaces to ensure good adhesion of the paint.

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

- Q: Can aluminum sheets be welded or joined together?

- Indeed, welding or joining together aluminum sheets is possible. Aluminum possesses excellent weldability, allowing for its fusion through diverse welding techniques such as gas tungsten arc welding (GTAW), gas metal arc welding (GMAW), and laser welding. These methods involve the application of heat to liquefy the aluminum sheets and establish a robust connection. Furthermore, mechanical fasteners like screws, rivets, or adhesive bonding can also be employed to join aluminum sheets. The selection of the welding or joining approach hinges upon the particular application and the desired result.

Send your message to us

PVDF Coated 1060-H14 Aluminium Sheet and Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 3000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords